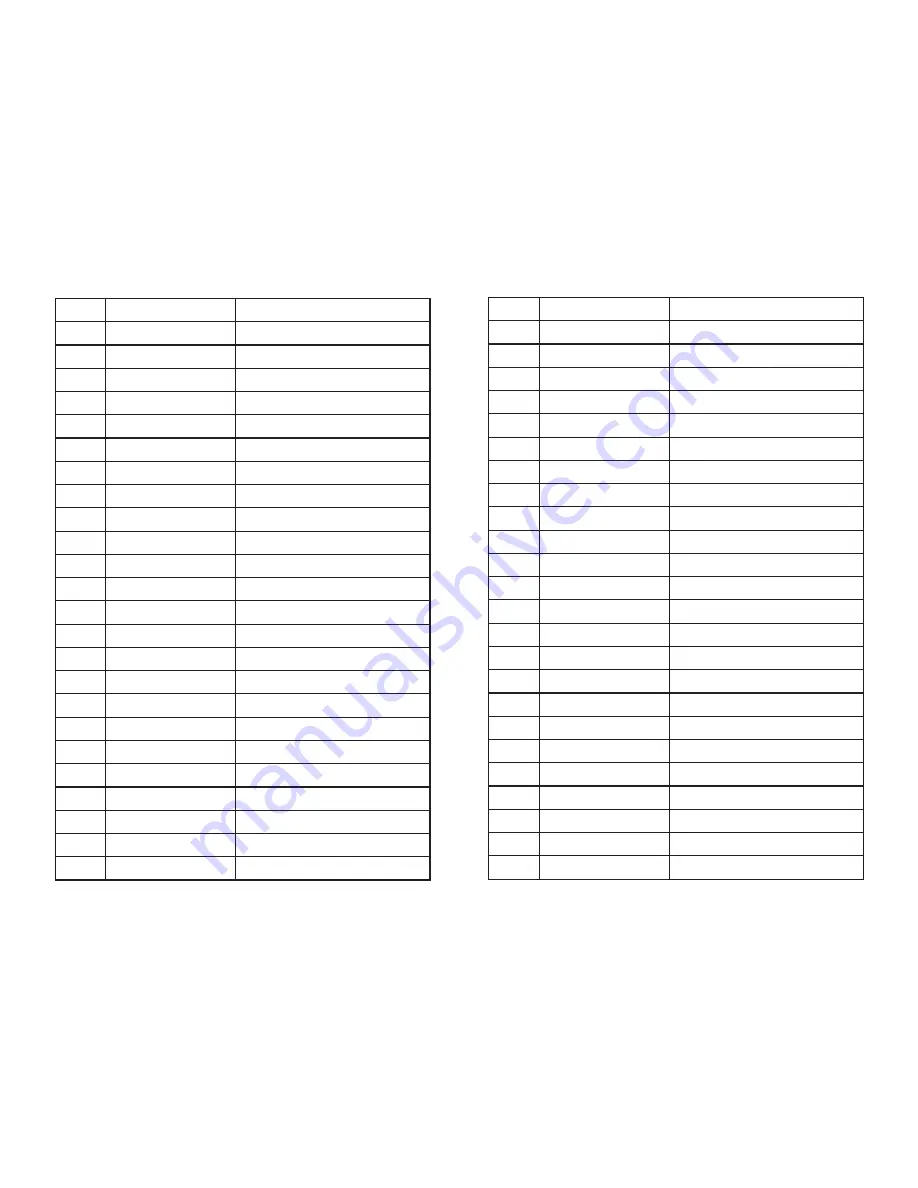

ITEM NO.

PART NO.

DESCRIPTION

24

ITEM NO.

PART NO.

DESCRIPTION

23

50

A0401-2031

Body

51

A0004-0021

Nylon Nut M5

52

K0500-1501

Trigger Set

53

A0011-0201

Spring Pin 3*30

54

A0009-0011

Steel Ball

55

A0100-1961

Spring

56

B0000-0351

Lock Pin Set

57

A0000-0411

Nylon Screw M5*20

58

A0712-1191

Catch Cover

59

A0201-0122

Bushing

60

A0711-2021

Lower Safety B

61

A0711-2001

Lower Safety A

62

A0204-1081

No Mar Pad

63

A0106-0101

Spring Clip

64

A0713-0881

Guide Body

65

A0100-2151

Spring

66

A0000-0891

Screw M8*25

67

A0713-0341

Feeder Shoe Stop

68

A0309-0731

Bumper

69

A0200-0791

O-Ring 63.9*2.5

70

A0200-1101

O-Ring 7*2

71

K1100-2421

Magazine Set

72

A0706-1371

Support

73

A0708-0392

Steel Bar

74

A0713-0352

Insert

25

A0200-3221

O-Ring 58*2.5

26

A0200-1952

O-Ring 57.5*3.3

27

A0303-0811

Cylinder

28

A0800-0781

Spacer

29

A0200-2002

O-Ring 85*3.5

30

A0311-0351

Sleeve Hold Down

31

A0305-0131

Collar

32

K0500-0901

Trigger Valve Set

33

A0313-0651

Main Body Bumper

34

A0712-1181

Release Guide

35

A0011-0091

Spring Pin 3*20

36

A0005-0131

E-Ring 4

37

A0719-1211

Hook Fixer

38

A0000-1791

Nylon Screw M5*28

39

A0005-0531

Washer 14*1T

40

A0100-1051

Outlet Spring

41

A0011-0071

Spring Pin 3*16

42

A0000-0351

Screw M3*8

43

A0706-1711

Support

44

A0316-0341

Hook

45

A0204-1671

Grip

46

A0306-1201

Tail Cover

47

A0011-0161

Spring Pin 3*24

48

A0203-0191

Filter

49

A0200-3011

O-Ring 50*3