CLEARING JAMS

Typically, jams are caused when a fastener or a fastener fragment becomes wedged

between the driver blade and nail guide. Using the wrong fastener can also cause jams.

TO CLEAR A JAM:

1. Disconnect the air supply and

remove the fastener strip. Leave the

pusher assembly open.

2. Loosen hex screws from back of

magazine and pull magazine back.

See Figure 9.

3. Remove jammed fastener.

4. Slide magazine back in position and

refasten hex screws (Figure 10).

MAINTENANCE

STORAGE OF NAILS

Always handle nail strips and their box very carefully. If the nail strips have been mis-

handled, they may be out of shape or have breaks in the connecting strips. This will

cause the nails to feed poorly and possibly result in misfiring or jams in the air nailer.

Avoid storing nails in a very humid or hot environment or place in direct sunlight.

OVERALL MAINTENANCE OF AIR NAILER

Always disconnect the air hose from clipped head nail-

er before attempting any type of maintenance or visual inspection of tool.

DO NOT hold the trigger in a half-pulled position. This

could cause an unexpected nailing to occur if the work piece contact is permit-

ted to re-contact the work piece. Failure to comply could result in damage to

work piece.

LOCKING AND UNLOCKING THE TRIGGER

Always move lever to the locked position immediately

after using the nailer to prevent unintended firing of fastener.

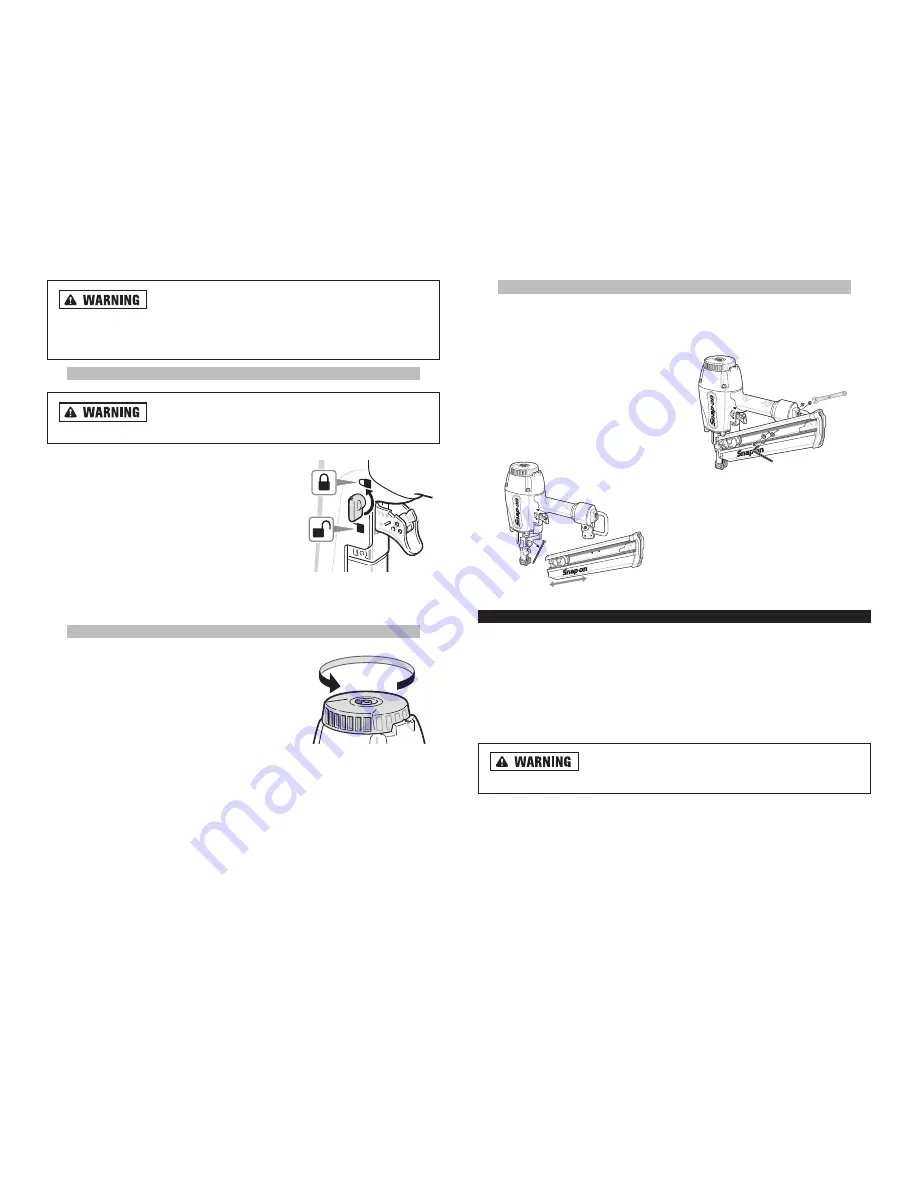

The clipped head nailer is equipped with a trigger

lock to prevent operation of the tool when not

actively being used. To lock trigger, move trigger

lock lever up to the locked position. To unlock trig-

ger in preparation for use, move the trigger lock

lever down to the unlocked position (Figure 7).

CHANGING DIRECTION OF EXHAUST AIR

The direction of exhaust air on the air nailer can be

directed 360˚ degrees by placing hand on exhaust

cover and turning. See Figure 8.

15

16

Figure 8

Figure 7

Figure 9

Figure 10