P

PR

RO

OB

BL

LE

EM

M

P

PO

OS

SS

SIIB

BL

LE

E C

CA

AU

US

SE

E

S

SO

OL

LU

UT

TIIO

ON

N

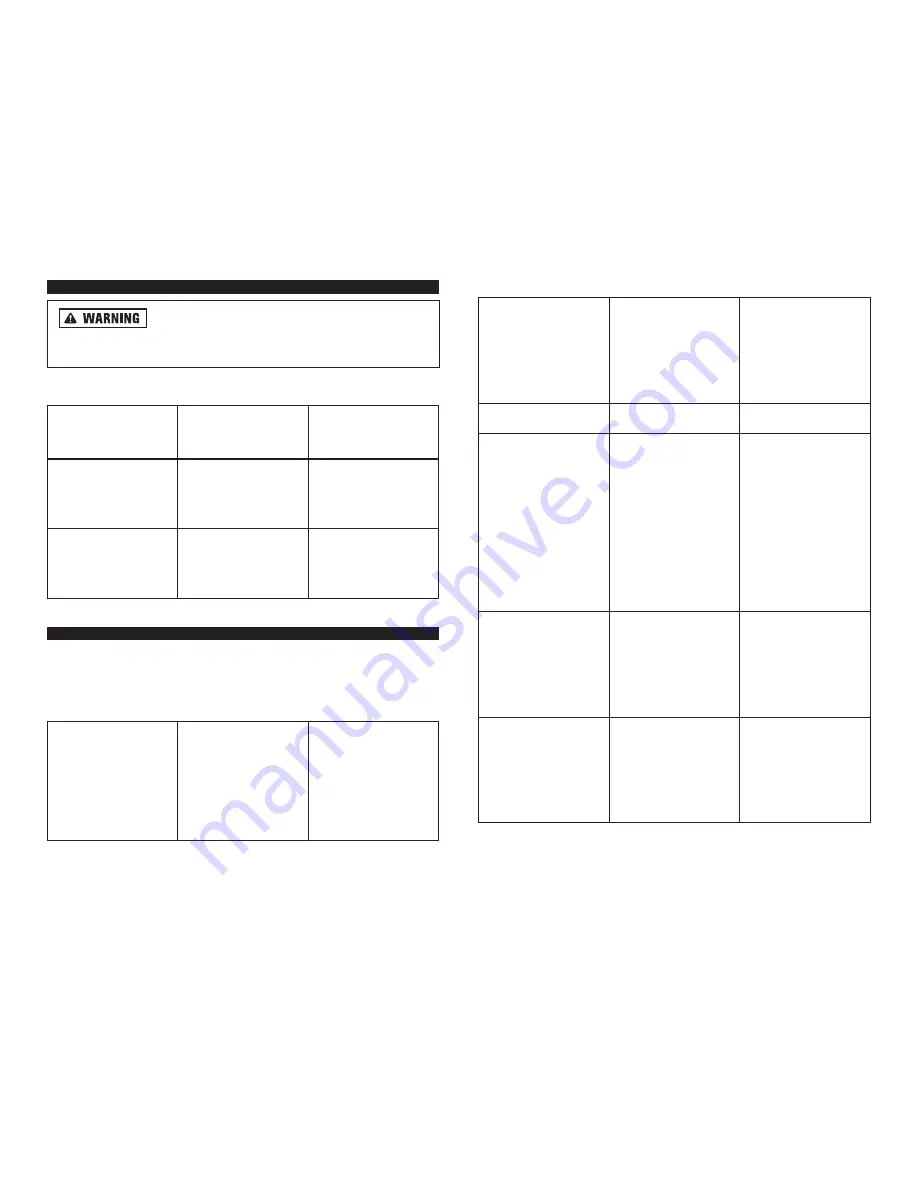

MANDATORY MAINTENANCE

A

Allll m

ma

aiin

ntte

en

na

an

ncce

e a

an

nd

d rre

ep

pa

aiirrss ssh

ho

ou

ulld

d b

be

e p

pe

errffo

orrm

me

ed

d b

byy a

an

n

a

au

utth

ho

orriizze

ed

d rre

ep

pa

aiirr ffa

acciilliittyy.. C

Ca

allll 1

1--8

88

88

8--2

27

78

8--8

80

09

92

2 tto

o o

ob

btta

aiin

n a

a lliisstt o

off rre

ep

pa

aiirr ffa

acciill--

iittiie

ess iin

n yyo

ou

urr a

arre

ea

a o

orr tto

o m

ma

akke

e a

arrrra

an

ng

ge

em

me

en

nttss tto

o rre

ettu

urrn

n tth

he

e tto

oo

oll ffo

orr sse

errvviicce

e..

A

AC

CT

TIIO

ON

N

R

RE

EA

AS

SO

ON

N

O

OP

PE

ER

RA

AT

TIIO

ON

N

TROUBLESHOOTING

Most minor problems can be resolved quickly and easily using the troubleshooting

table below. For problems that cannot be solved, contact Alltrade Customer Service

(toll free) at 1-888-278-8092.

P

PR

RO

OB

BL

LE

EM

M

P

PO

OS

SS

SIIB

BL

LE

E C

CA

AU

US

SE

E

S

SO

OL

LU

UT

TIIO

ON

N

Clean magazine and

feeder mechanism.

Prevents brad nailer

from jamming.

Use compressed air and

clean daily.

Inspect and ensure work

piece contact operates

properly.

Ensures operator safety

and keeps brad nailer

working efficiently.

Use compressed air and

clean daily.

Lubricate brad nailer

after every use using

pneumatic tool oil.

Extends life of brad nailer.

Apply 2 – 3 drops of

pneumatic tool oil to

brad nailer air inlet after

every use.

Weak drive. Slow to

cycle between nailings.

Ensure proper air pres-

sure is being used.

Inspect for worn driver

blade.

Inspect piston O-ring for

wear or damage.

Increase air pressure,

Do not exceed 120 psig

(8.3 bars, 8.5 kg/cm

2

)

Contact Customer

Service.

Nails driven too deep.

Check air pressure.

Reduce air pressure.

Brad nailer feeds inter-

mittently or skips nails.

Ensure correct nails are

being used.

Inspect nail feeder

mechanism.

Piston O-ring damaged

or worn

Nail feeder worn or

damaged.

Use ONLY recommend-

ed nails.

Clean and lubricate nail

feeder.

Use recommended

pneumatic tool oil.

Contact Customer

Service.

Replace nail feeder.

Nails jam or driven nail

is bent.

Ensure correct nails are

being used.

Inspect for worn driver

blade.

Nail feeder worn or

damaged.

Use ONLY recommend-

ed nails.

Contact Customer

Service.

Replace nail feeder.

Drives nails properly

during normal nailing

operations, but fails to

drive nails fully at faster

operating speeds.

Check inside diameter of

air hose.

Switch to air hose with

larger inside diameter.

Nailer operates, but no

nail is driven.

Check for jammed nail.

Inspect nail feeder

mechanism.

Ensure correct nails are

being used.

Clear jammed nail.

Clean and lubricate nail

feeder.

Use ONLY recommend-

ed nails.

17

18