O

OP

PE

ER

RA

AT

TIIO

ON

N IIN

N S

SIIN

NG

GL

LE

E S

SE

EQ

QU

UE

EN

NT

TIIA

AL

L A

AC

CT

TU

UA

AT

TIIO

ON

N M

MO

OD

DE

E

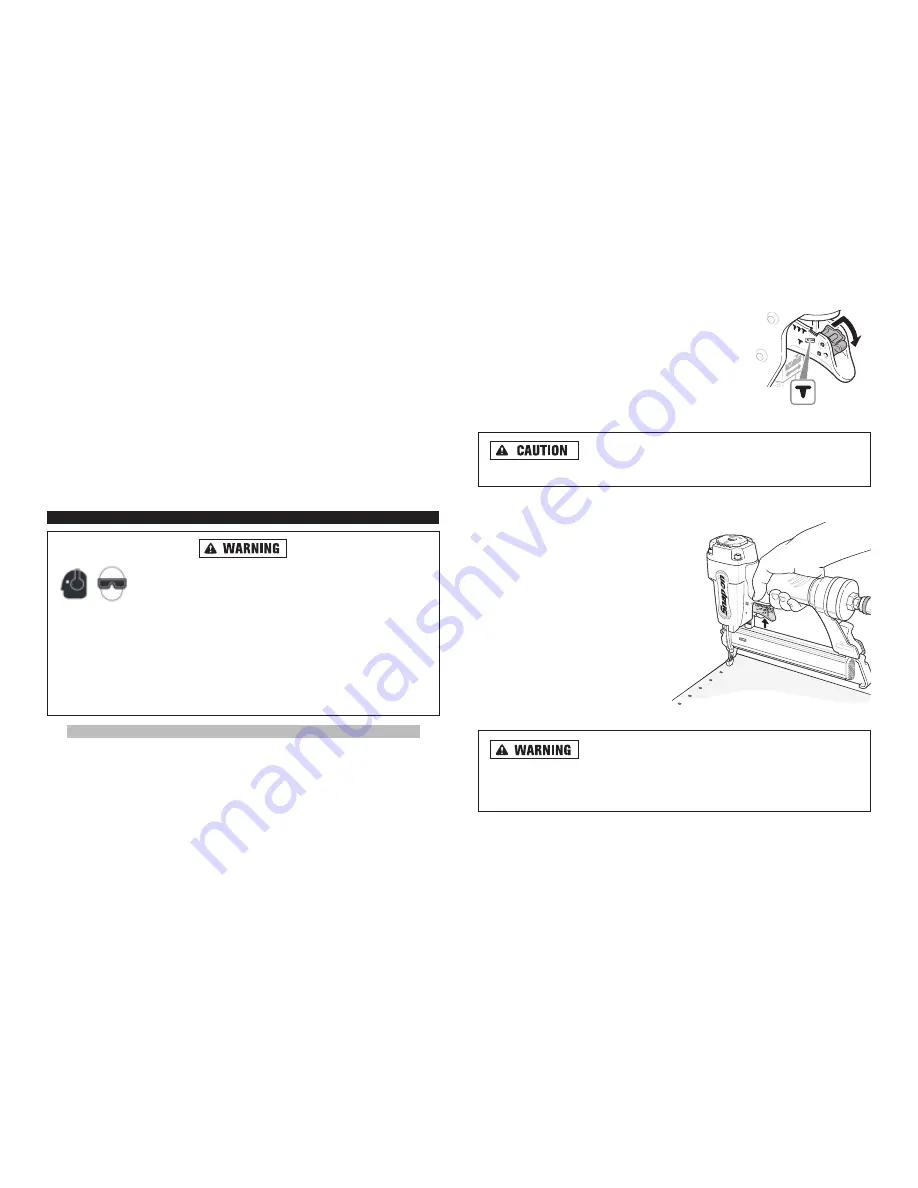

To select the Single Sequential Actuation Mode (see

Figure 1):

1. Press and hold the red Actuation Selector embedded

in the trigger.

2. Rotate Actuation Selector down to the Single

Sequential Actuation (T).

3. Release Actuation Selector, ensuring locking tab is

fully seated in the slot.

E

En

nssu

urre

e sse

elle

ecctto

orr h

ha

ass llo

occkke

ed

d iin

ntto

o p

po

ossiittiio

on

n.. E

En

nssu

urre

e

a

accttu

ua

attiio

on

n p

prro

occe

essss iiss ffu

ullllyy u

un

nd

de

errsstto

oo

od

d b

be

effo

orre

e a

atttte

em

mp

pttiin

ng

g tto

o u

usse

e b

brra

ad

d n

na

aiille

err..

T

TO

O U

US

SE

E T

TH

HE

E B

BR

RA

AD

D N

NA

AIIL

LE

ER

R IIN

N S

SIIN

NG

GL

LE

E S

SE

EQ

QU

UE

EN

NT

TIIA

AL

L

A

AC

CT

TU

UA

AT

TIIO

ON

N M

MO

OD

DE

E::

1. Firmly grip brad nailer handle.

2. Position brad nailer work piece con-

tact on work piece surface.

3. Push brad nailer against work piece

compressing work piece contact.

4. Pull trigger on brad nailer to drive

nail. The brad nailer will recoil away

from the work piece as nail is driven.

5. Remove finger from trigger and lift

brad nailer away from surface of work

piece.

O

OP

PE

ER

RA

AT

TIIO

ON

N IIN

N C

CO

ON

NT

TA

AC

CT

T A

AC

CT

TU

UA

AT

TIIO

ON

N M

MO

OD

DE

E

W

Wh

he

en

n u

ussiin

ng

g cco

on

ntta

acctt a

accttu

ua

attiio

on

n m

mo

od

de

e,, b

be

e cca

arre

effu

ull o

off u

un

niin

n--

tte

en

nttiio

on

na

all d

do

ou

ub

blle

e ffiirre

ess rre

essu

ullttiin

ng

g ffrro

om

m tto

oo

oll rre

ecco

oiill.. U

Un

nw

wa

an

ntte

ed

d ffa

asstte

en

ne

errss m

ma

ayy b

be

e

d

drriivve

en

n iiff tth

he

e w

wo

orrkk p

piie

ecce

e cco

on

ntta

acctt iiss a

allllo

ow

we

ed

d tto

o a

acccciid

de

en

ntta

allllyy rre

e--cco

on

ntta

acctt tth

he

e w

wo

orrkk

p

piie

ecce

e..

9

10

To improve the connection between the quick disconnect and air nailer, and to help

prevent oxidation, apply PTFE tape or joint compound to the connector threads

before insertion.

3. Snap the air hose onto the quick disconnect on the air nailer. Check for air

leaks.

L

LU

UB

BR

RIIC

CA

AT

TIIO

ON

N

To ensure maximum performance, it is recommended to install an air set (oiler, reg-

ulator, and air filter) as close as possible to the air nailer. Adjust the oiler so that

approximately one drop of oil will be released for every 50 nails.

If an air set is not used or is unavailable, oil the tool using pneumatic tool oil by plac-

ing 2 or 3 drops into the air inlet. This should be done before and after use. For

proper lubrication, the tool must be fired several times after the oil is introduced to

the filter.

OPERATING THE BRAD NAILER

A

Allw

wa

ayyss u

usse

e h

he

ea

arriin

ng

g p

prro

otte

eccttiio

on

n tto

o p

prro

otte

ecctt yyo

ou

urr e

ea

arrss a

ag

ga

aiin

nsstt

h

he

ea

arriin

ng

g llo

ossss d

du

ue

e tto

o e

exxh

ha

au

usstt n

no

oiisse

e.. A

Allw

wa

ayyss w

we

ea

arr p

prro

op

pe

err ssa

affe

e--

ttyy g

glla

asssse

ess tto

o p

prre

evve

en

ntt iin

njju

urriie

ess tto

o tth

he

e e

eyye

ess ffrro

om

m ffrra

ag

gm

me

en

nttss o

off

tth

he

e w

wo

orrkk p

piie

ecce

e,, d

de

effe

eccttiivve

e n

na

aiillss o

orr o

otth

he

err d

de

eb

brriiss cca

au

usse

ed

d b

byy u

ussiin

ng

g tth

he

e b

brra

ad

d n

na

aiill--

e

err.. All safety glasses must have side shields and should conform to the require-

ments of the American National Standards Institute (ANSI) z87.1. Failure to

comply with this warning could lead to serious or permanent damage to the

ears as well as serious damage or permanent blindness in the eyes.

A

Allw

wa

ayyss d

diisscco

on

nn

ne

ecctt tth

he

e a

aiirr h

ho

osse

e b

be

effo

orre

e m

ma

akkiin

ng

g a

ad

djju

ussttm

me

en

nttss o

orr cch

he

ecckkiin

ng

g tth

he

e

ffu

un

nccttiio

on

na

alliittyy o

off tth

he

e a

aiirr n

na

aiille

err..

SELECT TRIGGER ACTUATION MODE

The brad nailer is equipped with a selectable trigger. This allows the selection of

S

Siin

ng

glle

e S

Se

eq

qu

ue

en

nttiia

all A

Accttu

ua

attiio

on

n M

Mo

od

de

e or C

Co

on

ntta

acctt A

Accttu

ua

attiio

on

n M

Mo

od

de

e.

Figure 1