10 • Snap-on

Brake Lathes

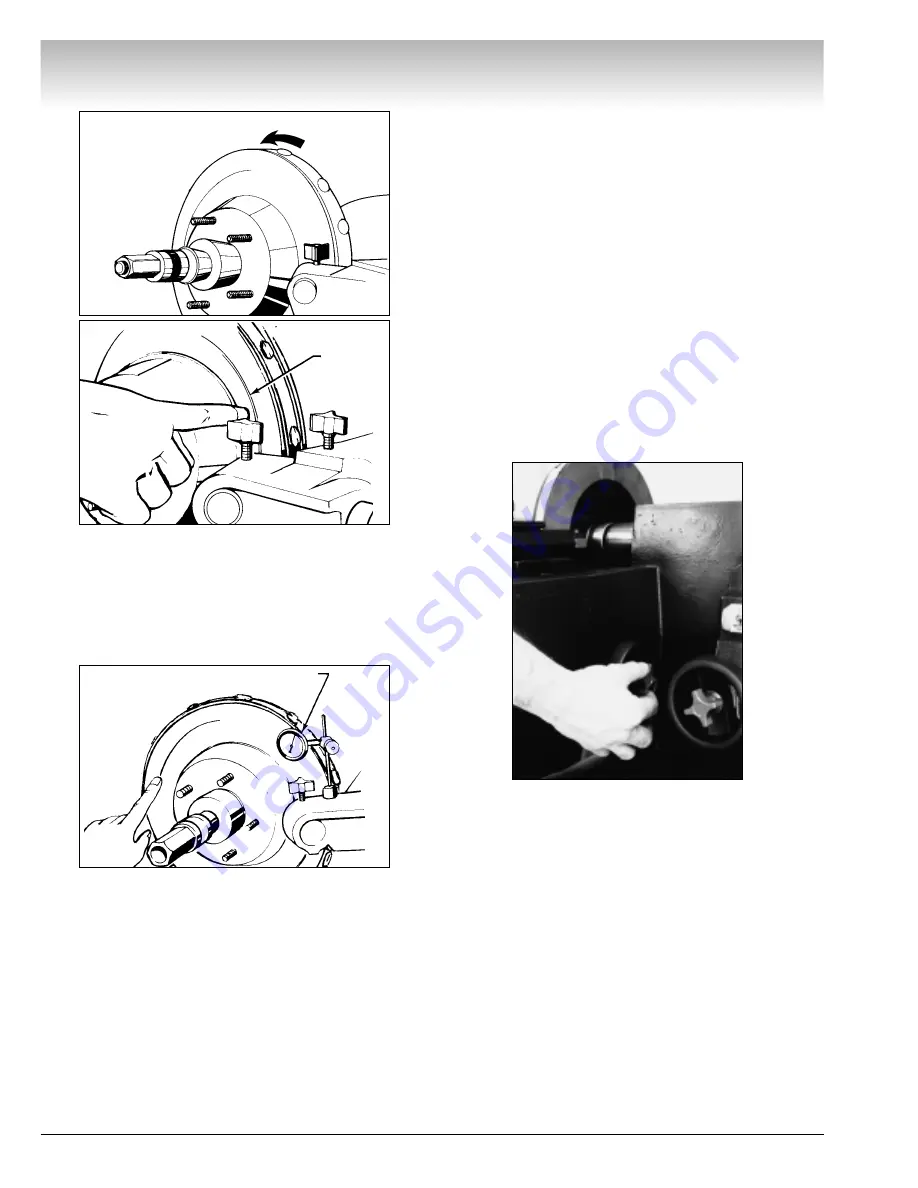

Figures 8 & 9

11.

Check rotor mounting by loosening the arbor

nut and turning the rotor 180° by hand on the arbor.

Make sure the inside adapter does not rotate along

with the rotor. Then retighten the arbor nut, turn the

rotor slide handwheel back 1/2 turn, turn the lathe ON,

and repeat step 10 to make a second scratch cut.

Figure 10

12.

If the scratch cuts are side-by-side, the runout

or wobble is caused by rotor condition. A dial indicator

may be used to compare rotor runout with manufac-

turer’s specifications.

13.

If the scratch cuts are opposite one another

(180°), the rotor may not be properly mounted on the

arbor. Remove the rotor and examine the arbor and all

adapters for nicks, burrs, chips, dirt, or rust. Inspect

the rotor hub for loose or damaged bearing cups.

Clean, repair, remount, or replace as necessary.

14.

Recheck the setting of the depth-of-cut collars,

which were set to zero earlier by moving the tool bits

inward until they just contact the surfaces of the rotor.

The collars should be at zero. Reset the collars if nec-

essary.

15.

Turn the rotor slide handwheel clockwise until

the tool bits are near the rotor hub.

16.

Turn the lathe ON.

17.

Turn both tool bit controls to the desired depth-

of-cut and lock them in position by tightening the red

lock knobs above the tool bits.

Note:

Either rough or finish cuts may be taken to

resurface a rotor. Generally, finish cuts should be

0.004" (0.10 mm) to 0.006" (0.15 mm) per side. Very

shallow cuts of less than 0.004" (10 mm) per side tend

to reduce tool bit life because the heat generated dur-

ing reconditioning isn’t transferred to the rotor effi-

ciently. Rough cuts may be taken from 0.006" to 0.010"

per side.

Figure 11

18.

Tighten the engagement knob in the center, the

rotor slide handwheel, to engage rotor slide feed.

When the tool bits have cleared the outer edge of the

rotor, loosen the engagement knob to stop the feed.

19.

Turn the lathe OFF and inspect both surfaces.

20.

If part of the brake surface was not cut, leave

the twincutter in the locked position. Turn the lathe

ON. Slowly turn the rotor slide handwheel clockwise

to move the left tool bit to the groove at the bottom of

the brake surface.

21.

Repeat steps 18, 19, 20, and 21.

Note:

If one side of the rotor was fully cut and the

other only partially cut, recut the fully cut side at a

.002" depth-of-cut, for support, and the partially cut

side as needed.

Rotate rotor only 180°

Loosen arbor

nut, do not turn

inside adapter

Second

scratch cut

Scratch cuts

opposite each

other

Dial indicator