13

Snap-On EEWH329A

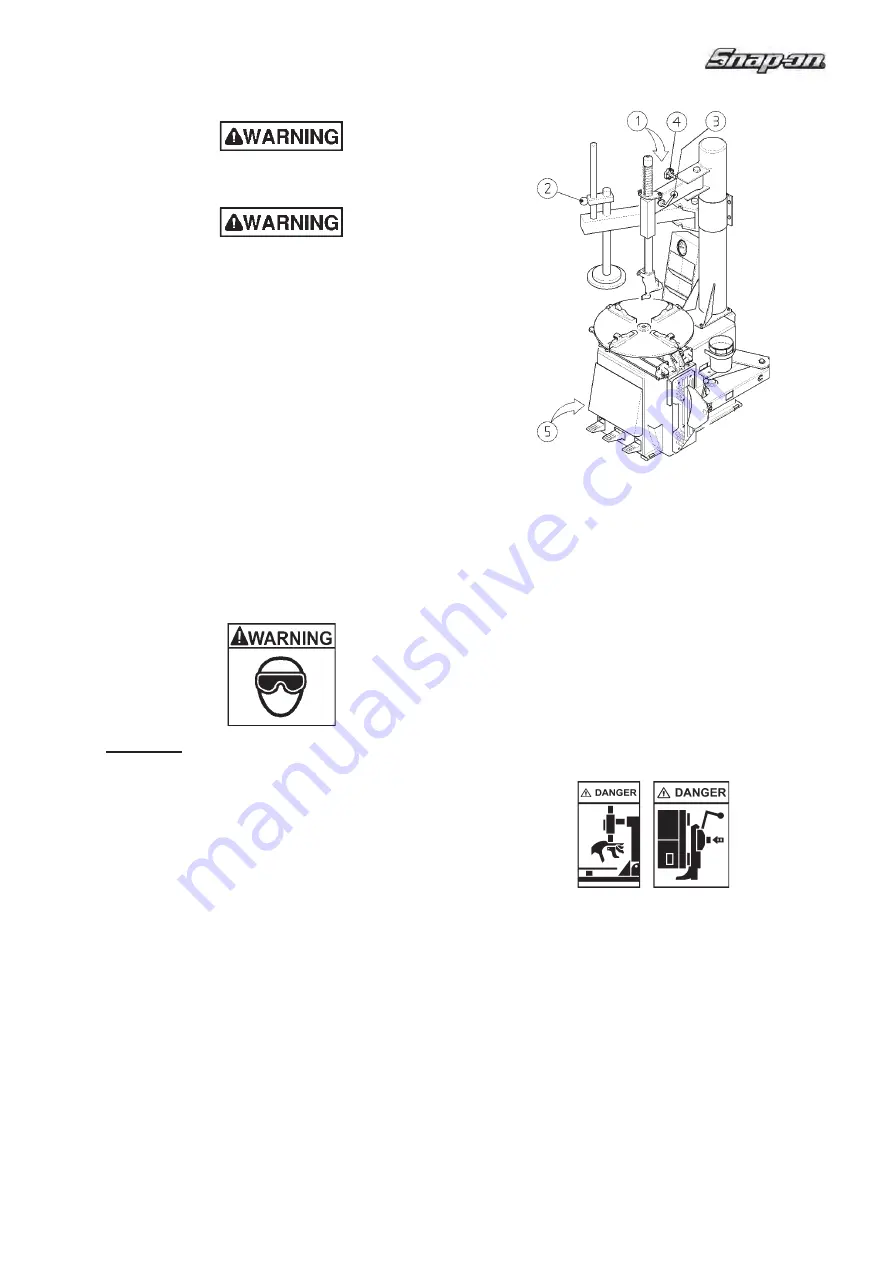

3.0 CONTROLS

889

Figure 3.0-1

Before operating the machine, take the time to

familiarize yourself with the operation and function of

all the controls.

A

Press down and release the fi rst pedal from the left:

the jaws of the turntable will retract. Do it again:

the jaws will expand. If you press the pedal prior

to the end of the stroke and release, the jaws may

be stopped in any position.

B

Open the bead breaker arm. Press down and hold

the middle pedal: by doing this you operate the

bead breaker blade and the arm will move towards

the machine. Release the pedal: the bead breaker

blade will retract.

WARNING!

ALWAYS KEEP ARMS AND LEGS AWAY FROM THE

BEAD BREAKER STROKE!!

C

Press down the right pedal: the turntable turns

clockwise. Placing your foot under the pedal and

lift, the turntable turns counterclockwise.

D

Lower the Lock Lever

(3)

to unlock the vertical

slide; lift the Lock Lever to lock.

2.3 AIR INSTALLATION

THE AIR INSTALLATION MUST BE MADE ONLY BY

QUALIFIED PERSONNEL.

EXCESSIVE AIR PRESSURE CAN SERIOUSLY

INJURE PERSONNEL AND DAMAGE THE MACHINE.

Ensure that the line pressure is within the limits

required by the machine. If the pressure exceeds

170 psi (12 bar) it is mandatory to install a pressure

regulator before the air inlet of the machine.

If the air pressure is lower than the minimum required of

110 psi (8 bar) the clamping power of the turntable and

the bead breaker power may be insuffi cient for certain

tires and substantially reduces tire changer performance.

It is suggested that the shop air supply be equipped

with a water separator/dryer type modifi cation for

maximum performance.

After ensuring all the above proceed as follows:

A.

Connect the machine to the air supply with a rubber

hose (rated for the pressure) with an internal diameter

of no less than 1/2” (12.5mm).

WARNING! BEFORE CONNECTING THE MACHINE

TO THE AIR SUPPLY BE SURE ALL PERSONNEL

ARE CLEAR OF THE MACHINE AND NO ITEMS

ARE LEFT ON THE TURNTABLE.

B.

It is strongly recommended that an air valve shut-off be

installed between the shop air supply and the tire changer

for routine maintenance and in case of an emergency.

C.

Should you install any optional accessories, please

refer to the relevant instructions.

D.

Ensure the functional ability of the air lubricator by

ensuring that the glass sight bowl is fi lled with air lubricant.

Summary of Contents for EEWH329A

Page 25: ...25 Snap On EEWH329A Blank Page ...

Page 28: ...28 Snap On EEWH329A ...

Page 51: ...51 Snap On EEWH329A Page blanche ...

Page 54: ...54 Snap On EEWH329A ...