5

Safery

Safety Rules and Information

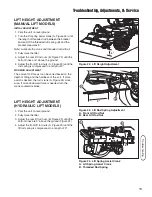

Slope Operation

You could be seriously injured or even killed if you use this unit on too

steep an incline. Using the unit on a slope that is too steep or where

you don’t have adequate traction can cause you to lose control or roll

over.

A good rule of thumb is to not operate on any slope you cannot back up

(in 2-wheel drive mode). You should not operate on inclines with a

slope greater than a 3.5 foot rise over a 20 foot length. Always drive up

and down slopes: never cross the face.

Also note that the surface you are driving on can greatly impact stability

and control. Wet grass or icy pavement can seriously affect your ability

to control the unit.

If you feel unsure about operating the unit on an incline, don’t do it. It’s

not worth the risk.

Moving Parts

This equipment has many moving parts that can injure you or someone else.

However, if you are seated in the seat properly, and follow all the rules in this

book, the unit is safe to operate.

Do not allow anyone near the equipment while it is running!

To help you, the operator, use this equipment safely, it is equipped with an

operator-present safety system. Do NOT attempt to alter or bypass the system.

See your dealer immediately if the system does not pass all the safety interlock

system tests found in this manual.

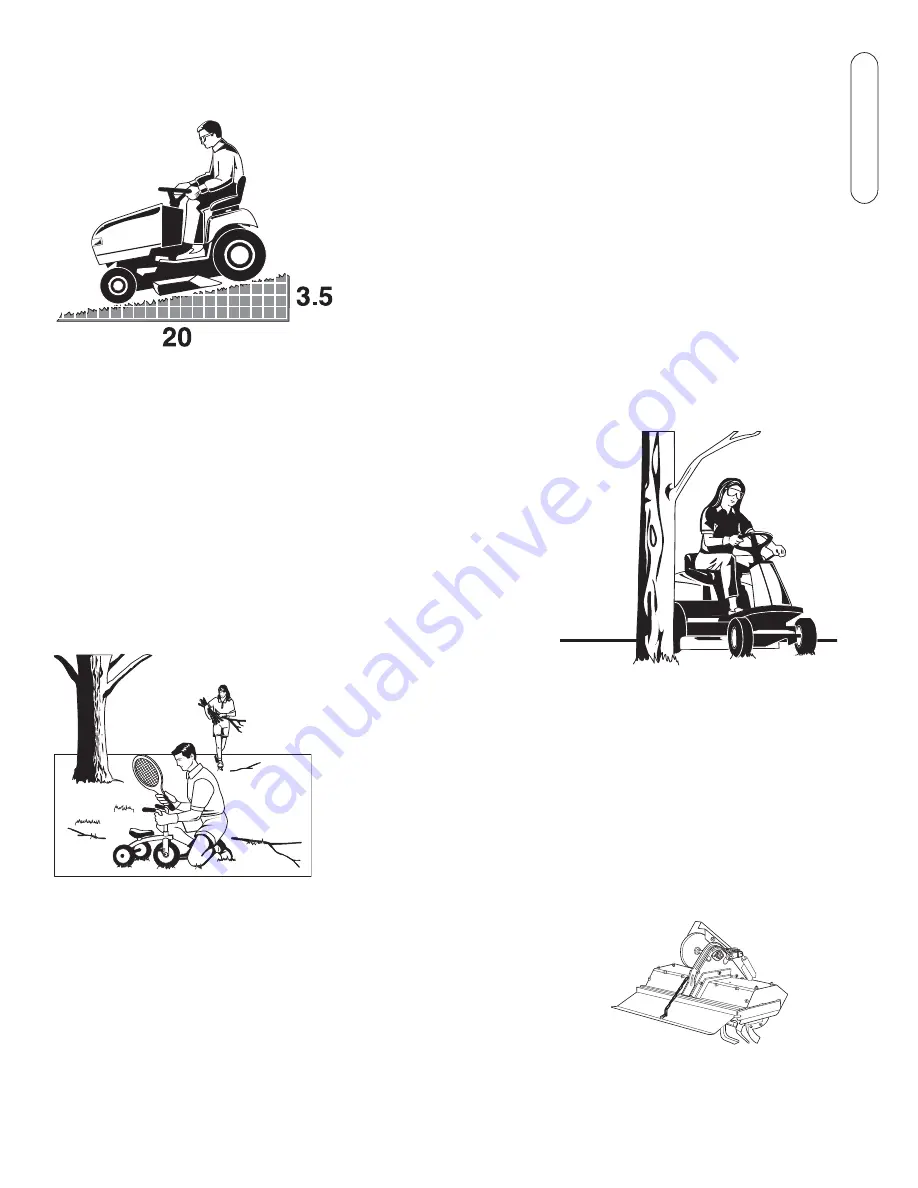

Thrown Objects

This unit has spinning mower blades. These blades can pick up and throw

debris that could seriously injure a bystander. Be sure to clean up the area to

be mowed BEFORE you start mowing.

Do not operate this unit without the entire grass catcher or discharge guard

(deflector) in place.

Also, do not allow anyone in the area while the unit is running! If someone

does enter the area, shut the unit off immediately until they leave.

Maintenance

Proper maintenance is critical to the safety and performance of your unit.

Be sure to perform the maintenance procedures listed in this manual,

especially periodically testing the safety system.

Summary of Contents for 1694151

Page 21: ...21 Notes NOTES...