2

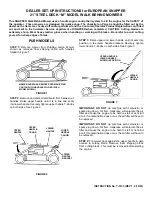

STEP 5: Handle height is adjustable for different height of

operators. Loosen the two nuts on the inside of each of

the lower handles. See Figure 4. Move the handle up or

down to the desired height. See Figure 5. Retighten all

nuts securely after adjustment. Pull blade control against

upper handle, pull rope start handle and loop into rope

guide. See Figure 5.

FIGURE 4

FIGURE 5

STEP 6: Set-up is now complete for push models

without self-propelled drive system. For self-propelled

models continue to the “Self-Propelled Models” Section.

Proceed to the pre-sale checklist page of this instruction

to prepare the mower for use.

SELF-PROPELLED MODELS

NOTE: The set-up procedure for self-propelled models is

basically the same as the Push Models. Follow the exact

procedure as described in Steps 1 thru 6 from the Push

Models section.

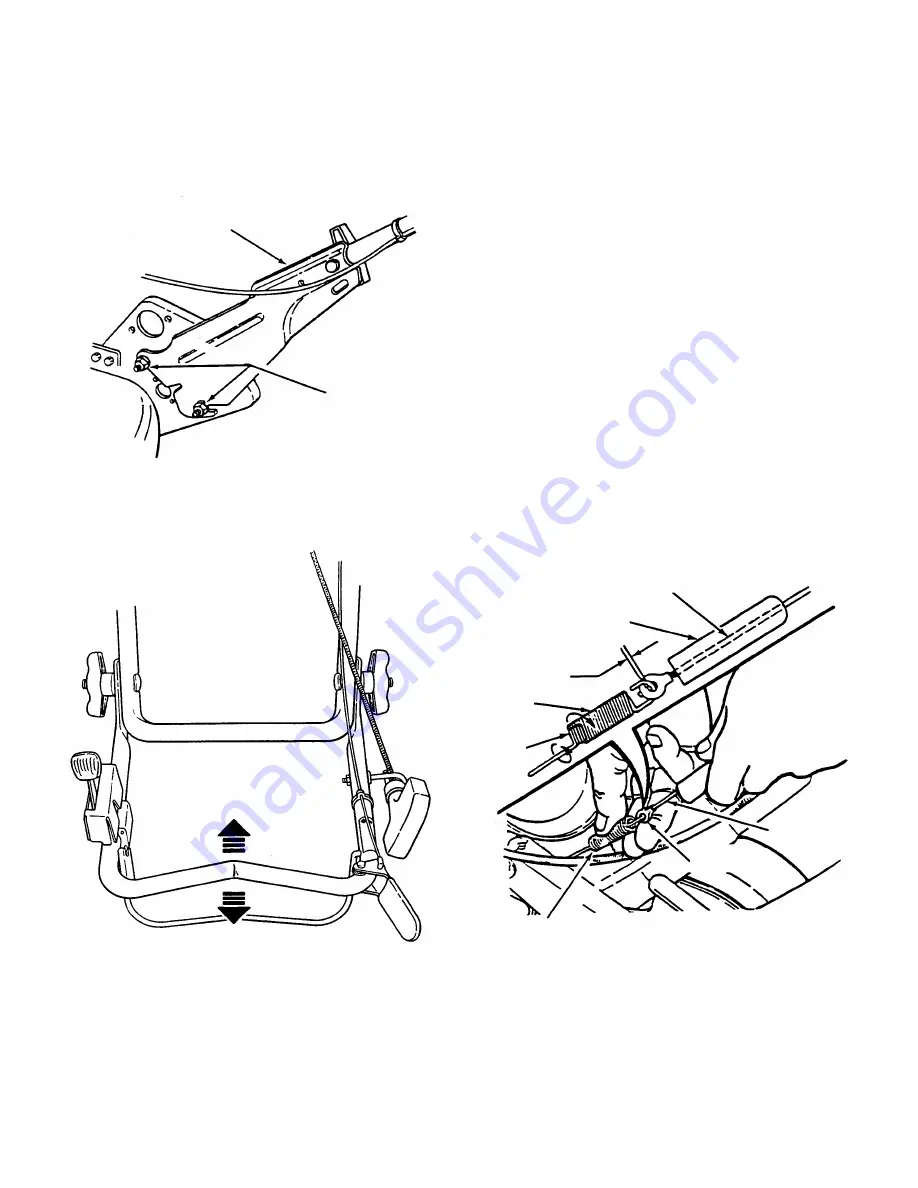

STEP 7: Check the clearance between the clutch cable

and clutch spring. NOTE: Clearance between spring and

cable is very important. Excessive clearance will cause

drive system NOT to operate when wheel drive control

handle is depressed. No clearance at all will cause

mower to continue to propel itself when wheel drive

control handle is released to stop mower movement.

Slide vinyl spring cover (located at the end of clutch

cable) up clutch cable to gain access to the end of spring

and cable loop. With wheel drive control handle

released, clearance between spring hook and cable loop

should be 1/16” to 1/8”. If clearance is more or less than

specified, unhook spring from clutch cable eye, then

adjust by rotating outer spring clockwise or counter

clockwise to achieve the proper clearance. Rehook

spring to clutch cable eye. Slide vinyl cover over the

spring when correct clearance is reached. See Figure 6.

FIGURE 6

LOWER HANDLE

BRACKET

LOOSEN

TWO NUTS

MOVE UPPER HANDLE

UP OR DOWN FOR

PROPER HEIGHT

CLUTCH CABLE

VINYL SPRING COVER

1/16” - 1/8”

CLEARANCE

OUTER

SPRING

INNER

SPRING

CABLE

CLUTCH

CABLE EYE

SPRINGS