3

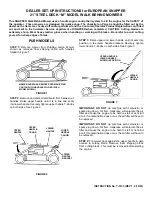

STEP 8: Driven disc to drive disc adjustment is set up at

the factory. In case driven disc may need adjustment,

proceed as follows:

A. Place speed control rod in the number six speed

position. See Figure 7.

FIGURE 7

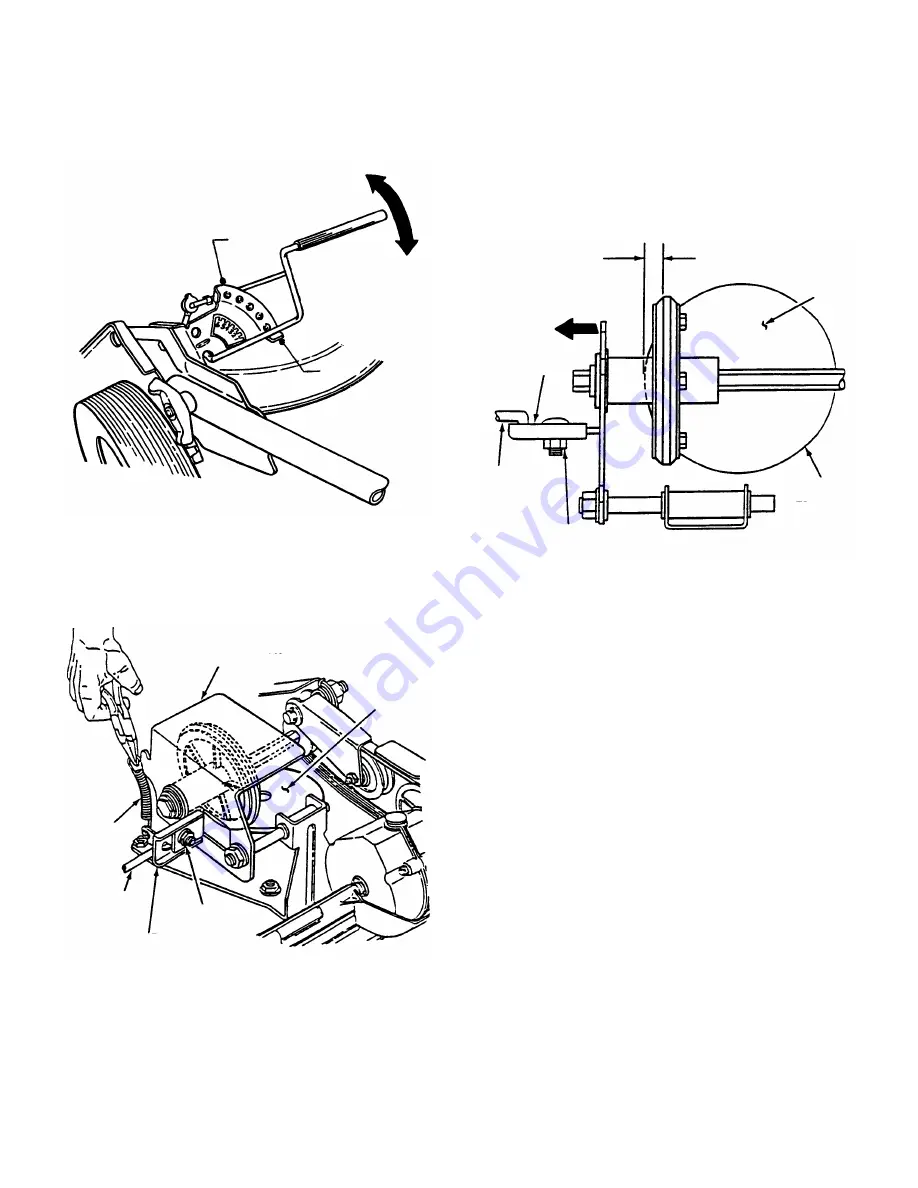

B. Remove driven disc spring from driven disc

assembly as shown. Loosen connector hex-nut. See

Figure 8.

FIGURE 8

C. Slide driven disc assembly over until 1/8” from

outside edge of drive disc. Maintaining the 1/8”

measurement, remove any looseness from the linkage.

This can be done by holding the transfer rod and

applying pressure to the left (as viewed from operators

position), then retighten the connector hex nut

securely. See Figure 9. Move shift rod to the number

one speed position, then back to the number six speed

position. Recheck the 1/8” measurement described

previously. Reinstall driven disc spring to driven disc

assembly.

FIGURE 9

STEP 9: Make sure all nuts and bolts are tight. Set-up is

now complete for self-propelled models Proceed to the

pre-sale checklist page of this instruction to prepare

mower for use.

MOVE GROUND SPEED

CONTROL TO SIX SPEED

POSITION

SIXTH SPEED

POSITION

SIXTH

FIRST SPEED

POSITION

FIRST

DRIVEN DISC

ASSEMBLY

DRIVE DISC

DRIVEN

DISC

SPRING

TRANSFER

ROD

CONNECTOR

CONNECTOR HEX

NUT

1/8” MEASUREMENT

TO OUTSIDE EDGE

OF DRIVE DISC

SLIDE DRIVEN

DISC ASSEMBLY

TOWARD

OUTSIDE EDGE

CONNECTOR

TRANSFER

ROD

CONNECTOR

HEX NUT

OUTSIDE

EDGE

DRIVE

DISC