16

Rider Maintenance Items

CLEAN DEBRIS FROM RIDER AND

ENGINE COMPARTMENT

Service Interval:

Before each use.

CAUTION: If debris is not removed from the engine

compartment and other hot surfaces, it creates a fire

hazard.

Before starting the unit at the beginning of the

mowing session, remove any grass clippings, dirt,

leaves, or other debris from the unit. Also clean out the

engine compartment.

CLEAN DEBRIS FROM ENGINE

COOLING AREAS AND AIR FILTER

Service Interval:

Before each use.

CAUTION: If debris is not removed from the engine

compartment and other hot surfaces, it creates a fire

hazard.

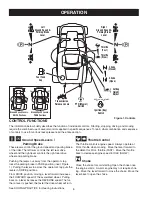

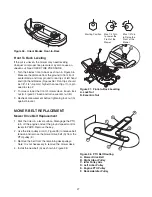

Before starting the unit at the beginning of the

mowing session, lift the seat deck and clean any debris

from the intake screen on top of the engine (A, Figure

13), exposed engine cooling fins, and around the air filter

assembly. Also open the air filter cover (B) and remove

any debris that has accumulated in the air filter compart-

ment.

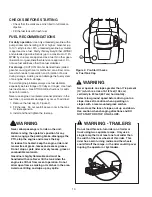

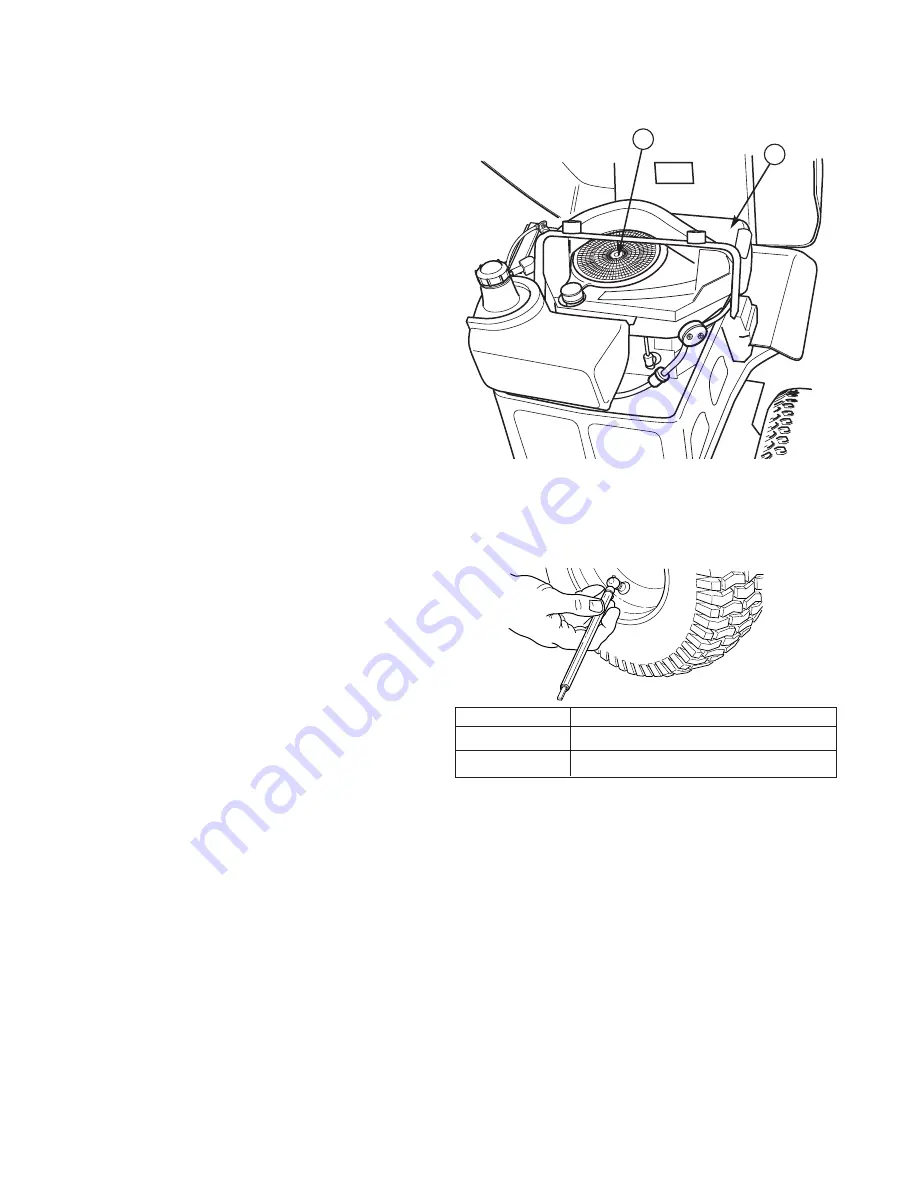

CHECK TIRE PRESSURE

Service Interval:

25 Hours.

Tire pressure should be checked periodically, and main-

tained at the levels shown in Figure 14. Note that these

pressures may differ slightly from the “Max Inflation”

stamped on the side-wall of the tires. The pressures

shown provide proper traction, improve cut quality, and

extend tire life.

Tire

Pressure

Front

18-20 psi (1,24-1,38 bar)

Rear

10-12 psi (,69-,83 bar)

Figure 13. Engine Compartment

A. Intake Screen

B. Air Filter Cover

Figure 14. Tire Pressures

A

B