33

Troubleshooting, Adjustment, & Service

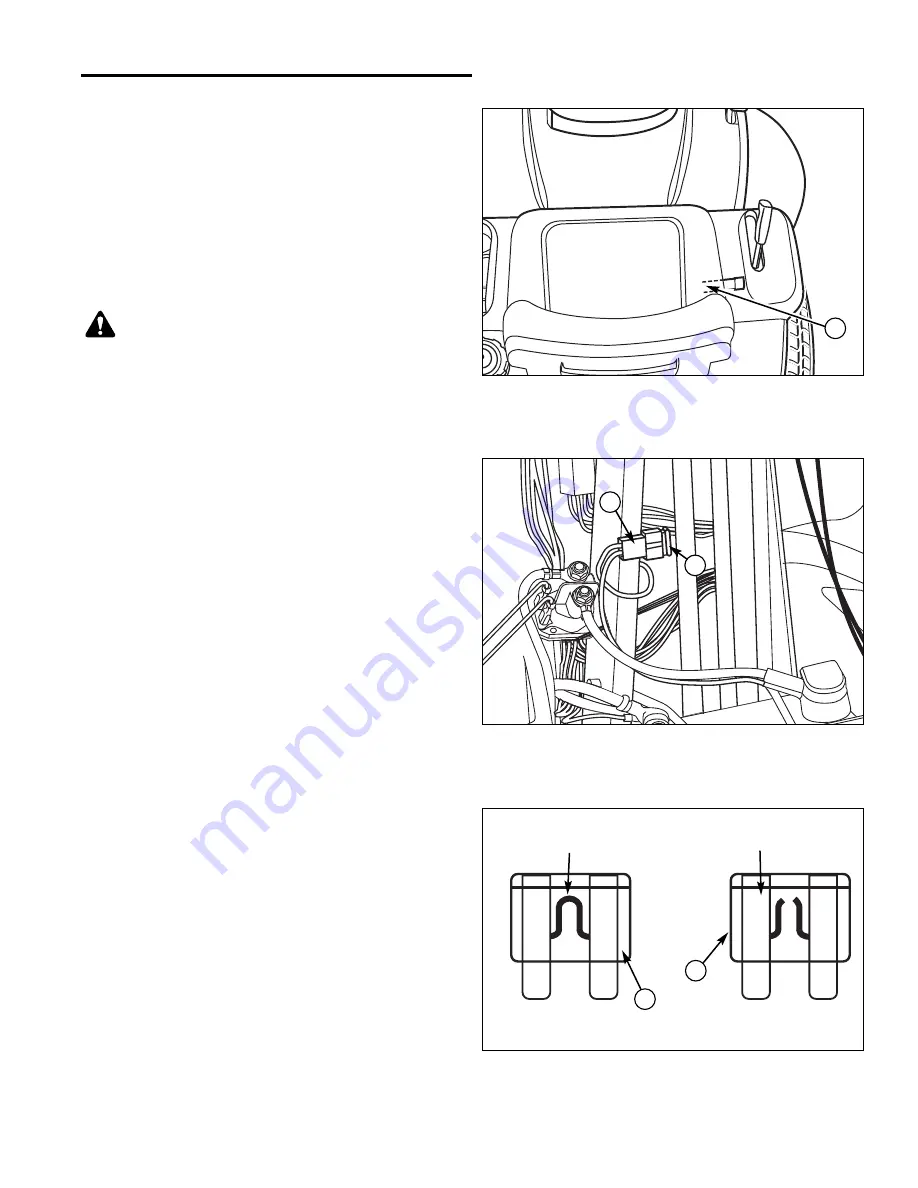

Figure 36. Seat Adjustment

A. Seat Adjustment Lever

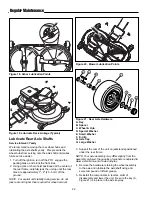

Figure 37. Fuse

A. Fuse, 20-amp

B. Fuse Holder

B

A

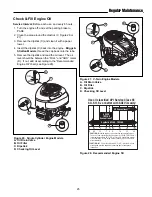

Figure 38. Blade Type Fuse

A. Good Fuse with Solid Fusible link

B. No Good Fuse with Broken Fusible link

Solid Fusible Link

Broken Fusible Link

B

A

Seat Adjustment

The seat can be adjusted forward and back. Move the

lever (A, Figure 36), position the seat as desired, and

release the lever to lock the seat into position.

Brake Adjustment

This unit does not have a manually adjustable brake.

If the brake does not function properly, see your dealer.

Battery Charging

WARNING

Keep open flames and sparks away from the

battery; the gasses coming from it are highly

explosive. Ventilate the battery well during

charging.

A dead battery or one too weak to start the engine may

be the result of a defect in the charging system or other

electrical component. If there is any doubt about the

cause of the problem, see your dealer. If you need to

replace the battery, follow the steps under “Cleaning the

Battery & Cables” in the Regular Maintenance Section.

To charge the battery, follow the instructions provided by

the battery charger manufacturer as well as all warnings

included in the “Safety Rules” section of this book.

Charge the battery until fully charged. Do not charge at

a rate higher than 10 amps.

Fuse Replacement

The fuse is a 20-amp blade type automotive fuse located

behind the battery on the steering tower.

Replace only

with the same rated fuse: 20-amp.

To replace the fuse:

1. Open the hood and locate the fuse holder (B, Figure 37)

and fuse (A) attached to the steering tower.

2. Hold the fuse holder (B) and pull out the fuse (A).

3. Inspect the fuse for a broken fusible link (see Figure 38).

Replace fuse if connection is broken. If you are not sure

if the fusible link is broken, replace fuse.

4. Hold the fuse holder (B, Figure 37) and insert new fuse

(A) until it is seated properly.

A