28

www.SnapperPro.com

Regular Maintenance

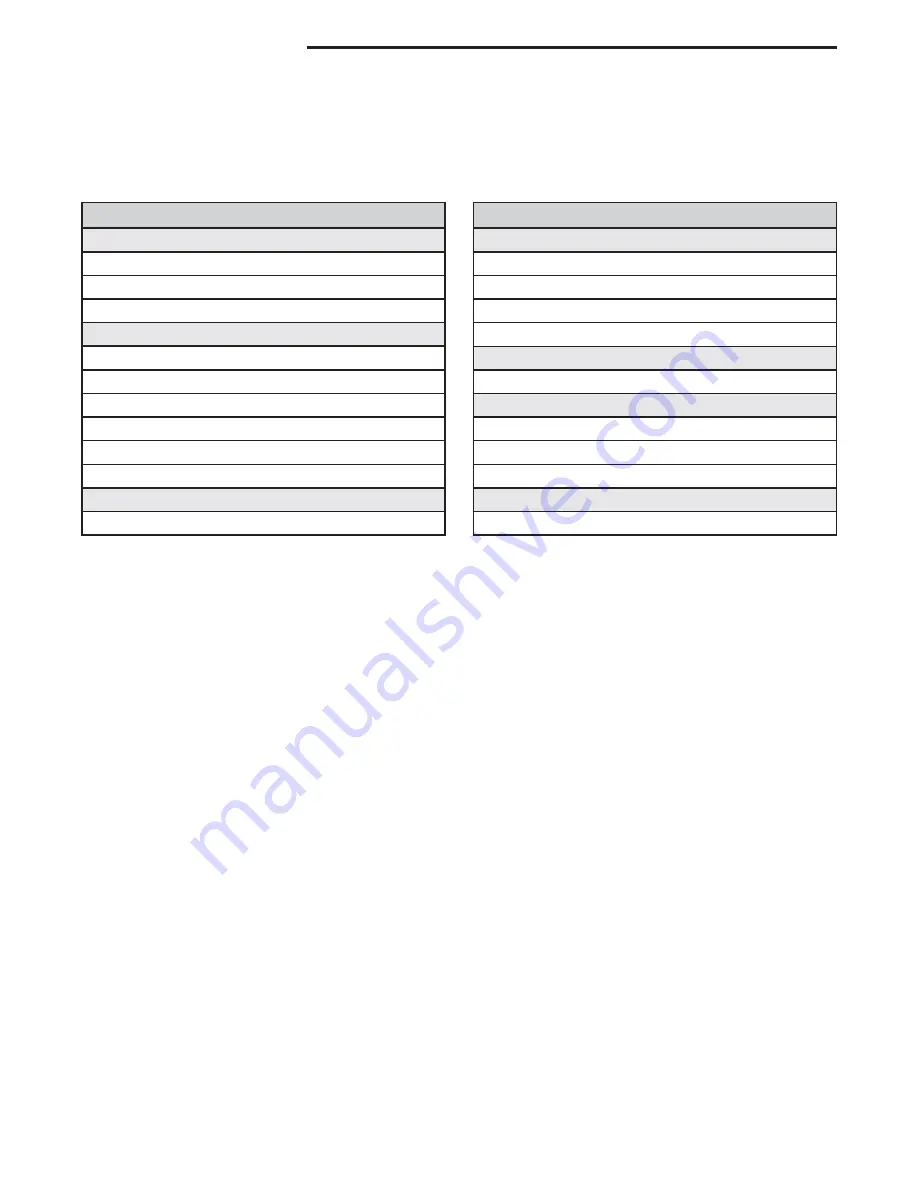

Maintenance

Maintenance Schedule & Procedures

The following schedule should be followed for normal care of your rider and mower. You will need to keep a

record of your operating time. Determining operating time is easily accomplished by observing the hour meter.

RIDER MAINTENANCE

Before Each Use

Check Safety Interlock System

Check Rider Brakes

Check Rider / Mower for loose hardware

Every 100 Hours or Annually*

Check Gearbos Oil Level***

Clean Deck & Check / Replace Mower Blades

Lubricate Rider & Mower**

Clean Battery & Cables

Check Tire Pressure

Check Hydraulic Oil**

Every 250 Hours or Annually*

Change Hydraulic Oil Filter**

ENGINE MAINTENANCE

Before Each Use

Check Engine Oil Level

Check Engine Coolant Level

Check & Clean Radiator Screens

Check / Clean Cooling Fins & Intake**

Every 25 Hours

Check Fuel Filter / Drain Water Seperator

Refer to Engine Manufacturer’s Owner’s Manual

Service Air Filter**

Change Oil & Filter

Check / Replace Spark Plugs

Annually

Change Engine Coolant

* Whichever comes first.

** More often in hot (over 85° F; 30° C) weather or

dusty operating conditions

*** Change gearbox oil after first 100 hours and every

500 hours thereafter

(See Gearbox Maintenance).

* Change original engine oil after first 5 hours of

operation.

** More often in hot (over 85° F; 30° C) weather or

dusty operating conditions.

Not

for

Reproduction