3

STEP 6

INSTALL OPERATOR PROTECTIVE

STRUCTURE (OPS)

The installation of the Operator Protective Structure

requires two people. The mounting hardware for the

OPS and seat belts must be properly torqued. Do Not

modify the OPS in any way. Install the OPS with the

“WARNING” sign on the right (passenger’s) side of the

machine.

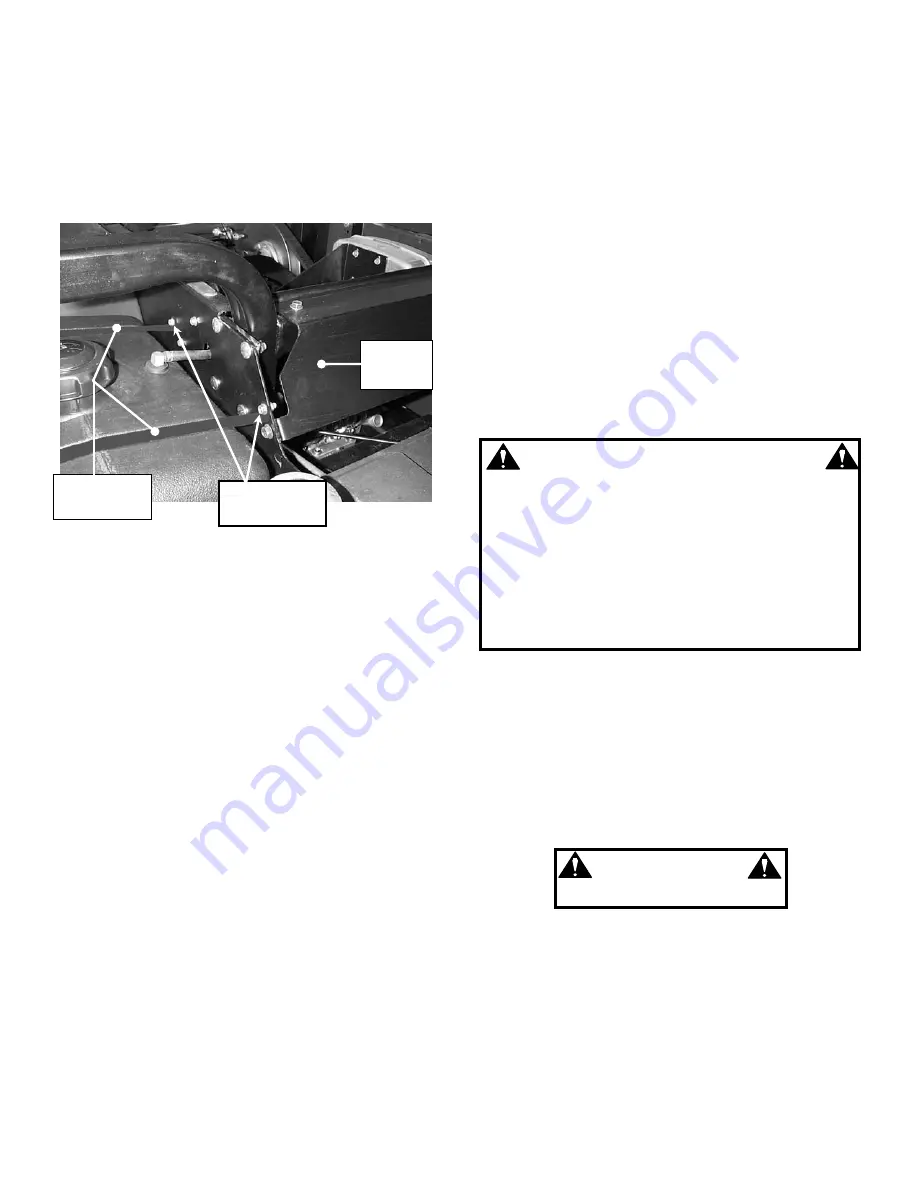

FIGURE 1.4

1. Locate the mounting hardware – (12) 3/8-16 x 1”

round head carriage bolts and (12) 3/8-16 Nyloc

nuts. Place 6 of each in the left and right seat

support tray for easy access when attaching OPS

to frame.

2. Raise OPS to vertical position and orientate so that

the “WARNING” decal located on the side of the

OPS is on the passenger’s side of the machine.

3. Align holes in OPS with holes in frame. Get (1)

carriage bolt started on each side. NOTE: insert

bolts with head towards outside of frame as shown.

Secure with 3/8-16 Nyloc nut. Do not tighten at this

time.

4. Install remainder of the bolts and secure each with

a Nyloc nut.

5. Torque ALL OPS mounting hardware to 30-35 ft-lb.

6. Reattach fuel tank straps. Tighten hardware

securely.

7. Attach heat shield to OPS using (2) 5/16-18 self-

tapping bolts. Do Not tighten at this time.

8. Attach heat shield to left and right frame rails using

(2) 5/16-18 x 7/8” bolts and (2) 5/16-18 NyLoc nuts.

9. Tighten all heat shield hardware securely.

10. Reattach fuel tank straps. Tighten hardware

securely.

STEP 7

ENGINE OIL AND TRANSMISSION FLUID

The engine oil and transmission fluid must be checked

before operation.

1. Fill engine crankcase to proper level. Refer to

Engine Owner’s Manual for capacity and oil

specifications. Check with dipstick unthreaded.

2. Check transmission fluid level. Bring to full level as

necessary using MOBILFLUID 424 or equivalent.

Check with dipstick fully threaded.

STEP 8

ACTIVATE BATTERY

Battery is located under the operator’s seat. Remove

battery from compartment before activating or charging.

Activate and charge the battery in well ventilated area

away from sparks and flame. Do Not smoke.

1. Remove battery from the battery compartment

before charging.

2. Place battery in a well ventilated area on a level

non-concrete surface.

WARNING

The electrolyte (acid) produces a highly explosive gas.

Keep all sparks, flame and fire away from area when

charging battery or when handling electrolyte or

battery. Electrolyte (acid) is a highly corrosive liquid.

Wear eye protection. Wash affected areas immediately

after having eye or skin contact with electrolyte (acid).

Battery acid is corrosive. Rinse empty acid containers

with water and mutilate before discarding. If acid is

spilled on battery, bench, or clothing, etc., Flush with

clear water and neutralize with baking soda.

3. Remove battery cell caps. Fill cells as required with

electrolyte (purchased separately) to proper level.

Fill to 3/16” above cell plates. Filling battery with

electrolyte will bring the battery to 80% of full

charged state.

IMPORTANT: 3/16” above cell plates is the

recommended level. Never place anything in battery other

than specified electrolyte.

WARNING

DO NOT OVERFILL!

4. With cell caps removed, connect battery charger to

battery terminals; RED to positive (+) and BLACK

to negative (-) terminal.

5. Slow charge the battery at 4 to 6 amps for 2 hours

to bring the battery to full charge.

6. After charging, check level of electrolyte and add as

needed to bring level to 3/16” above cell plates.

7. Reinstall cell caps. Tighten securely to prevent

leakage.

FUEL TANK

STRAPS

REMOVE TOP

TWO BOLTS

HEAT

SHIELD