17

Section 4 - REPAIR & ADJUSTMENTS

WARNING

DO NOT attempt any maintenance, adjustments or

service with engine and blade running. STOP engine

and blade. Disconnect spark plug wire and secure

away from spark plug. Engine and components are

HOT. Avoid serious burns, allow sufficient time for

all components to cool.

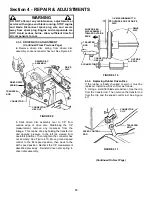

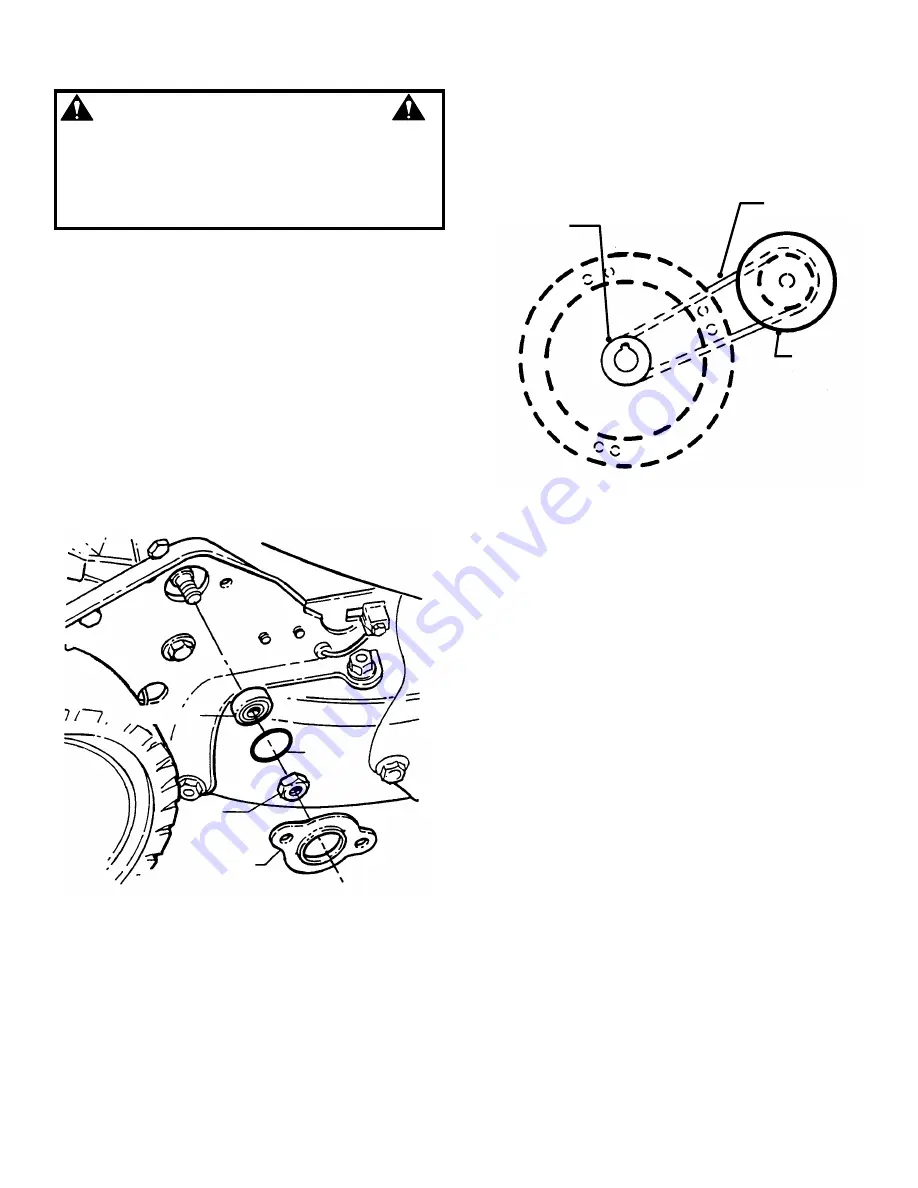

4.3.6. Replacement Of Bearing On Pulley End Of

Hex Shaft

To replace the bearing on the pulley end of the hex

shaft, proceed as follows:

1. Hold the hex shaft with an adjustable wrench

held next to the pulley.

2. Remove the 3/8” hex lock nut, which is located

on the outside of the right wheel bracket. See

Figure 4.14.

3. Remove holder, O-ring and bearing.

4. Install new bearing.

5. Carefully install new O-ring over the outside of the

new bearing.

6. Install bearing holder and secure with screws.

7. Install 3/8” hex lock nut.

FIGURE 4.14

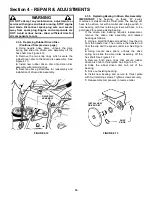

4.4 BELT

SERVICE

On self-propelled mowers, the engine belt transmits

power from engine to drive disc. The drive disc

powers the poly-v belt, which engages the

transmission that powers the rear wheels. Should

these belts become worn, they could cause slippage,

which would impair mower performance. The

condition of the engine belt and poly-v belt should be

checked after every 25 hours of mower operation.

4.4.1. Engine Drive Belt Replacement

(Stretch Type Belts)

1. Empty the fuel tank.

2. Note the belt routing in Figure 4.15. There is no

idler pulley on these models to disconnect. See Figure

4.15.

TOP VIEW OF STRETCH TYPE BELT ROUTING

FIGURE 4.15

(Continued On Next Page)

BALL BEARING

“O” RING

3/8”

LOCK NUT

BALL BEARING

HOLDER

DRIVE DISC

DRIVE BELT

ENGINE DRIVE

PULLEY