7

Section 2 - OPERATING INSTRUCTIONS

2.1 PRE-START CHECK LIST

Make the following checks and perform the service

required before each start-up.

2.1.1. Check tires and add or release air as needed

to bring pressure to 12 P.S.I. in front and 12 P.S.I. in

rear tires.

2.1.2. Check guards, deflectors and covers to make

sure all are in place and securely tightened.

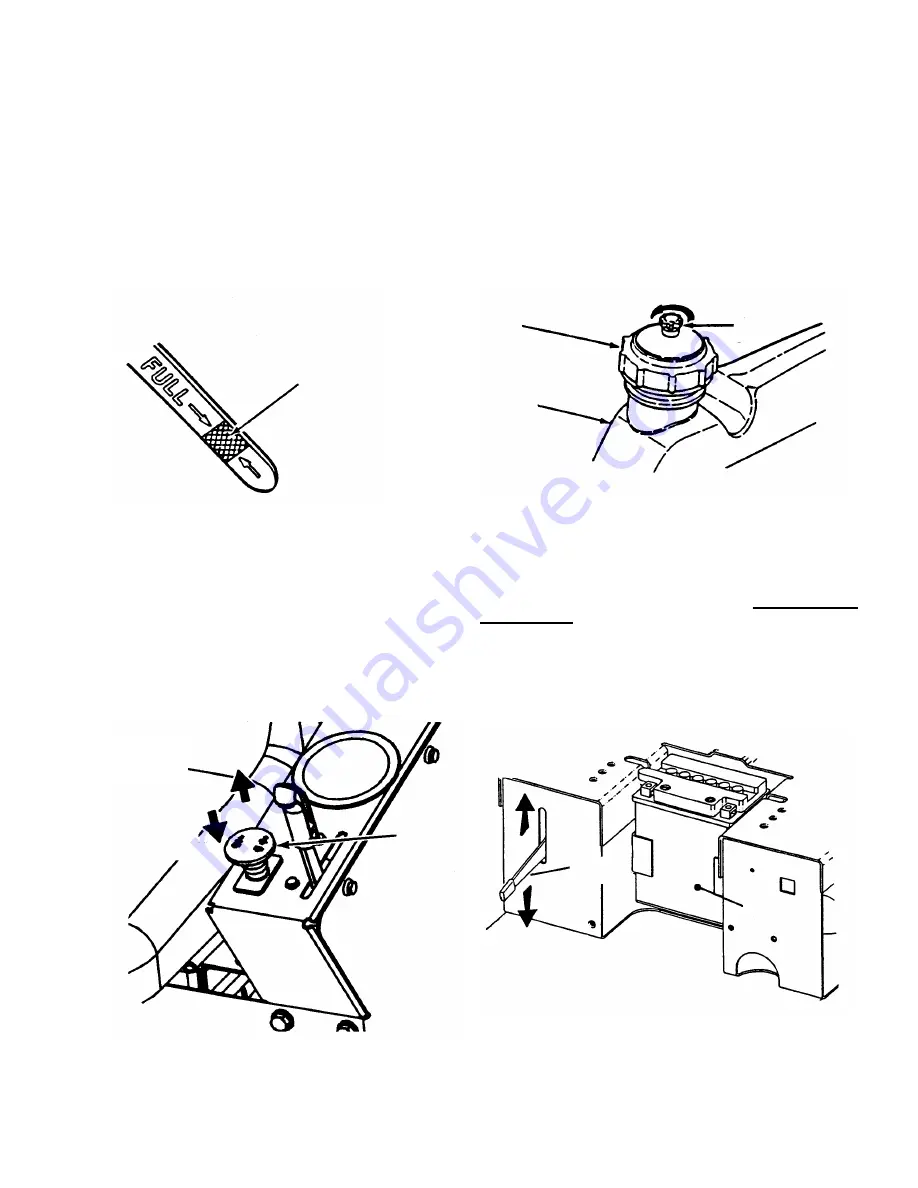

2.1.3. Check engine oil and add oil as needed to

bring level up to the FULL mark. Refer to engine

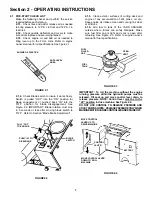

owner’s manual for oil specifications. See Figure 2.1.

FIGURE 2.1

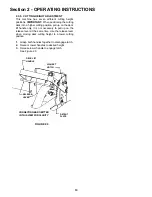

2.1.4. Check Blade switch to insure it works freely.

Switch is pulled “OUT” into the “ON” position for

blade engagement or pushed back “IN” into the

“OFF” position for blade disengagement. See

Figure 2.2. IMPORTANT: Blade rotation must stop

in 5 seconds or less after moving blade switch to

“OFF”. Refer to Section “Blade Brake Adjustment”.

FIGURE 2.2

2.1.5. Clean exterior surfaces of cutting deck and

engine of any accumulation of dirt, grass, oil, etc.

Keep engine air intake screen and cooling fins clear

at all times.

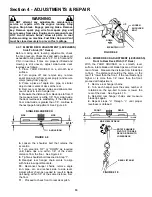

2.1.6. Add fuel to tank of the YARD CRUISER

outside where fumes can safely dissipate. Make

sure fuel filler cap is tight and vent is open after

refueling. See Figure 2.3. Refer to engine owner’s

manual for fuel specifications.

FIGURE 2.3

IMPORTANT: To roll the machine without the engine

running, pressure within the hydraulic pumps must be

released. Tilt seat up and move control lever down to

release pressure. NOTE: Control lever must be in the

“UP” position to drive machine. See Figure 2.4.

DO NOT USE CONTROL TO RELEASE PRESSURE AND

COAST DOWN SLOPES. RELEASE PRESSURE ONLY WHEN

MACHINE MOTION CAN BE CONTROLLED AND ENGINE OFF.

FIGURE 2.4

PULL “OUT”

TO ENGAGE

PUSH “IN” TO

DISENGAGE

BLADE

SWITCH

SAFE LEVEL

AREA

ENGINE OIL DIPSTICK

FUEL

FILLER

CAP

OPEN

VENT

FUEL

TANK

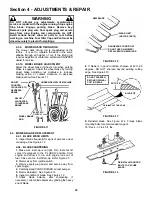

MOVE CONTROL

LEVER UP TO

DRIVE MACHINE

CONTROL

LEVER

BATTERY

MOVE CONTROL LEVER

DOWN TO ROLL

MACHINE

Summary of Contents for EYZ15334BVE

Page 27: ...28 PRIMARY MAINTENANCE...

Page 28: ...29 PRIMARY MAINTENANCE...

Page 29: ...30 PRIMARY MAINTENANCE...

Page 30: ...31 PRIMARY MAINTENANCE...