9

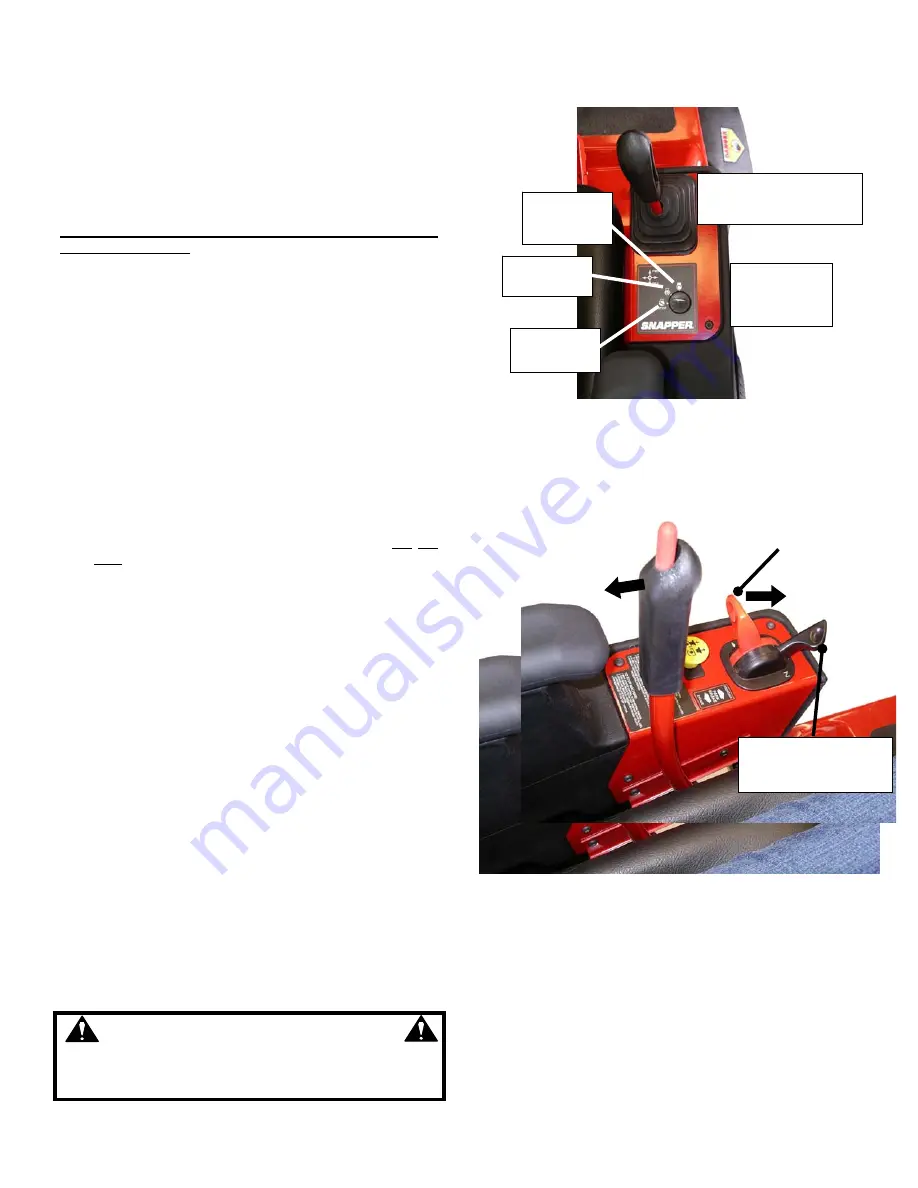

Section 2 - OPERATING INSTRUCTIONS

IMPORTANT: This SCRAMBLER is equipped with

hydrostatic drive. The forward, rearward and steering

movement of the machine is controlled by a joystick

lever. Joystick operations should be performed only

from the operator’s position in the seat. A small

movement of the joystick can cause the machine to

move instantly. Move joystick very carefully and slowly.

1. Always move the joystick to the center position to

“STOP” machine. IMPORTANT: To stop machine

always return the joystick with hand assistance to the

neutral position. Always engage parking brake when

leaving operator’s seat.

2. Move the joystick forward to propel the machine

forward.

3. Move the joystick rearward to propel the machine

backward.

4. Move the joystick to the right to rotate the front of

the machine in circular motion to the right, as in

turning around to go in a different direction.

5. Move the joystick to the left to rotate the front of the

machine in circular motion to the left, as in turning

around to go in a different direction.

2.2 STARTING & OPERATION

2.2.1. ENGINE (ELECTRIC START)

IMPORTANT:

When the ignition key is turned to

“START”, the engine will not turn over and will not

start unless the Parking Brake is engaged and the

Blade Switch is in the “Off” position. The operator

should be in the seat. Start engine as follows:

1.

Move joystick lever to (N) Neutral position. See

Figure 2.5.

2.

Make certain the blade switch is in the “Off”

position. See Figure 2.6.

3.

Make certain the parking brake is engaged. See

Figure 2.5.

4.

Open vent on fuel cap by turning

counterclockwise. Open fuel valve located in fuel

line.

IMPORTANT:

Failure to open vent and fuel

valve will cause engine to stall or not to start.

5.

Move choke control forward to the choke “ON”

position. See Figure 2.6.

6.

Move engine speed control forward to the “Fast”

(Rabbit) position. See Figure 2.6.

7.

Turn key to the “START” position until engine

starts. See Figure 2.5. NOTE: If after 5 seconds of

cranking the engine and it does not start, release the

key. Attempt starting again after waiting for

approximately 20 seconds.

8.

After engine starts, move choke control rearward

to the “OFF” position. Move engine speed control to

the desired speed position. Allow a brief warm-up

until engine runs smooth.

WARNING

DO NOT leave machine with engine running. STOP

engine. STOP blades. Engage park brake. Remove

key. DO NOT park machine on slopes.

FIGURE 2.5

FIGURE 2.6

RUN

POSITION

TURN KEY

TO START

POSITION

JOYSTICK IS IN

NEUTRAL POSITION

STOP

POSITION

START

POSITION

PARKING BRAKE

ENGAGED

MOVE CHOKE CONTROL

FORWARD TO “ON”

MOVE ENGINE

SPEED CONTROL

FORWARD TO FAST

(RABBIT) POSITION

Summary of Contents for EYZ16335BVE

Page 28: ...29 PRIMARY MAINTENANCE...

Page 29: ...30 PRIMARY MAINTENANCE...

Page 30: ...31 PRIMARY MAINTENANCE...

Page 31: ...32 PRIMARY MAINTENANCE...