14

Section 3 - MAINTENANCE

3.1 INTRODUCTION

To retain the quality of the SNAPPER Out Front Z-Rider,

use genuine SNAPPER replacement parts only. Contact a

local SNAPPER dealer for parts and service assistance.

For the correct part or information for a particular SNAPPER

Out Front Z-Rider, always mention the model and serial

number. SNAPPER recommends returning the Out Front

Z-Rider to an authorized SNAPPER dealer annually for

inspection and addition of any new devices which might

upgrade the safety of the Out Front Z-Rider. For the nearest

SNAPPER dealer in your area, check the yellow pages

under the heading LAWN MOWERS. For engine parts and

service, look for the engine manufacturer’s dealers under

the heading, ENGINES - gasoline.

3.2

SERVICE - AFTER FIRST 5 HOURS

WARNING

DO NOT attempt any adjustments, maintenance or

service with the engine or blades running. Stop

blades. Stop engine. Set brake. Remove key.

Remove spark plug wires from spark plugs and (gas

only) secure wires away from spark plugs. Engine

and components are HOT. Avoid serious burns by

allowing all parts sufficient time to cool.

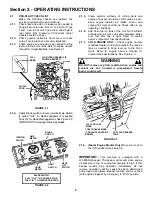

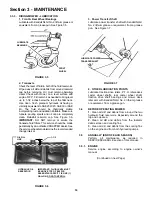

3.2.1. CHANGE ENGINE OIL

1. Place a 4 quart minimum capacity container

under the bottom of engine.

2. Remove the oil drain plug. See Figure 3.1.

FIGURE 3.1

3. After all the oil has drained, reinstall oil drain

plug and tighten securely. See Figure 3.1. Wipe

up any oil that may have spilled. Dispose of

drained oil properly.

4. Fill engine crankcase with new oil. Refer to your

engine owner’s manual for oil specifications.

5. Change oil filter at every oil change. Refer to

your engine owner’s manual for service

instructions.

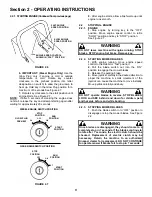

3.2.2.

CHECK MOWER BLADE

1. Stop Engine.

2. Engage parking brake.

3. Turn key to “ON” position but DO NOT start

engine. Raise mower deck off the ground using

deck lift switch located to the right of operator as

viewed from the operator’s position. Turn key to

“OFF” position. Remove key.

4. Use a hydraulic floor jack or hoist to raise deck

high enough to gain access to the underside of

deck. Secure deck with safety blocks.

WARNING

Wear heavy leather gloves when handling or working

around cutting blades. Blades are extremely sharp

and can cause severe injury. DO NOT use a cutting

blade that shows signs of excessive wear or

damage. Refer to Section “MOWER BLADE

REPLACEMENT” for proper blade inspection and

service procedures.

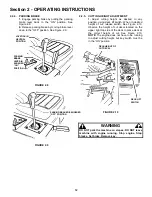

5. Check torque of blade mounting bolts. Torque

to 70 to 80 ft. lbs. See Figure 3.2.

6.

Check blade for sharpness, wear,

straightness and damage. Refer to Section

“BLADE WEAR LIMITS”.

FIGURE 3.2

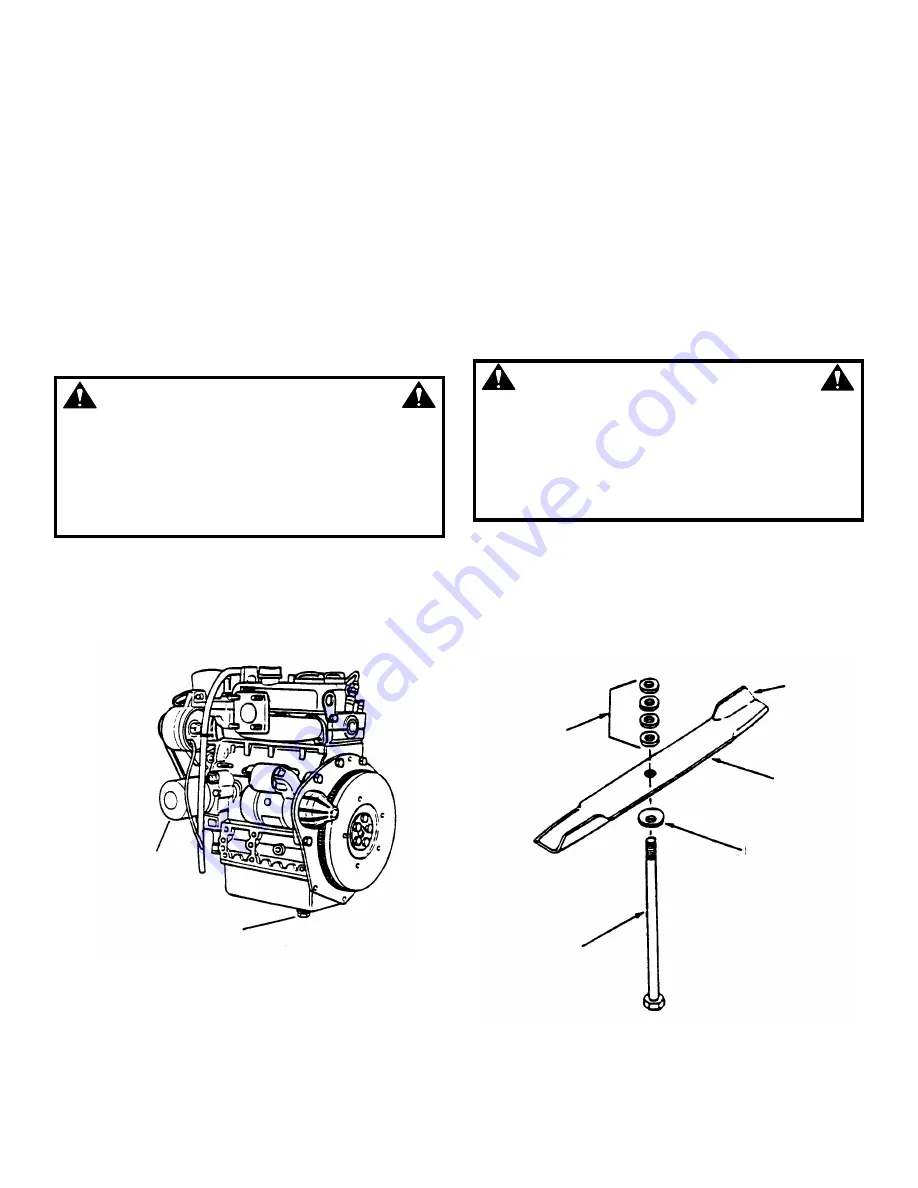

REMOVE OIL

FILTER

REMOVE OIL DRAIN

ENGINE IS VIEWED FROM THE REAR

(4) BLADE

SPACERS

AIR

LIFT

BLADE

BEVELED

WASHER

MOUNTING

BOLT

TIGHTEN TO 70-80

FOOT POUNDS

Summary of Contents for EZF2100DKU, EZF2300GKU, EZF520

Page 30: ...30 NOTES...

Page 31: ...31 NOTES...