Safety Instructions & Operator’s Manual for

21” STEEL DECK

WALK MOWERS

SERIES 17

PROPELLED MODELS

FRP2167517BV

MODEL NUMBER EXPLANATION

F R P 21

675

17

BV

MODEL DESIGNATION

ENGINE DESIGNATION

SELF-PROPELLED

SERIES DESIGNATION

CUTTING WIDTH

ENGINE HORSE POWER

F – Flange Type Deck

R – Recycling Model

675 – 6.75 HP (Engine Horse Power)

P – Self Propelled Model

17 – Series Designation

21 – 21” Cutting Width

B – Briggs & Stratton

V – Over Head Valve Engine

Thank you for buying a SNAPPER Product! Before operating your Walk Behind, read this manual carefully and pay

particular attention to the “IMPORTANT SAFETY INSTRUCTIONS” on Pages 2 & 3. Remember that all power

equipment can be dangerous if used improperly. Also keep in mind that SAFETY requires careful use in accordance

with the operating instructions and common sense.

COPYRIGHT © 2001

SNAPPER INC.

ALL RIGHTS RESERVED

MANUAL No. 7-4352 (I.R. 2/13/01)

Summary of Contents for FRP2167517BV

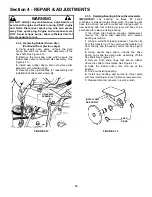

Page 22: ...22 PRIMARY MAINTENANCE...

Page 23: ...23 PRIMARY MAINTENANCE...

Page 24: ...24 PRIMARY MAINTENANCE...

Page 25: ...25 PRIMARY MAINTENANCE...