5

STEP 10 (Continued)

INSTALL OPERATOR’S AND PASSENGER’S

SEAT

FIGURE 1.7

STEP 11

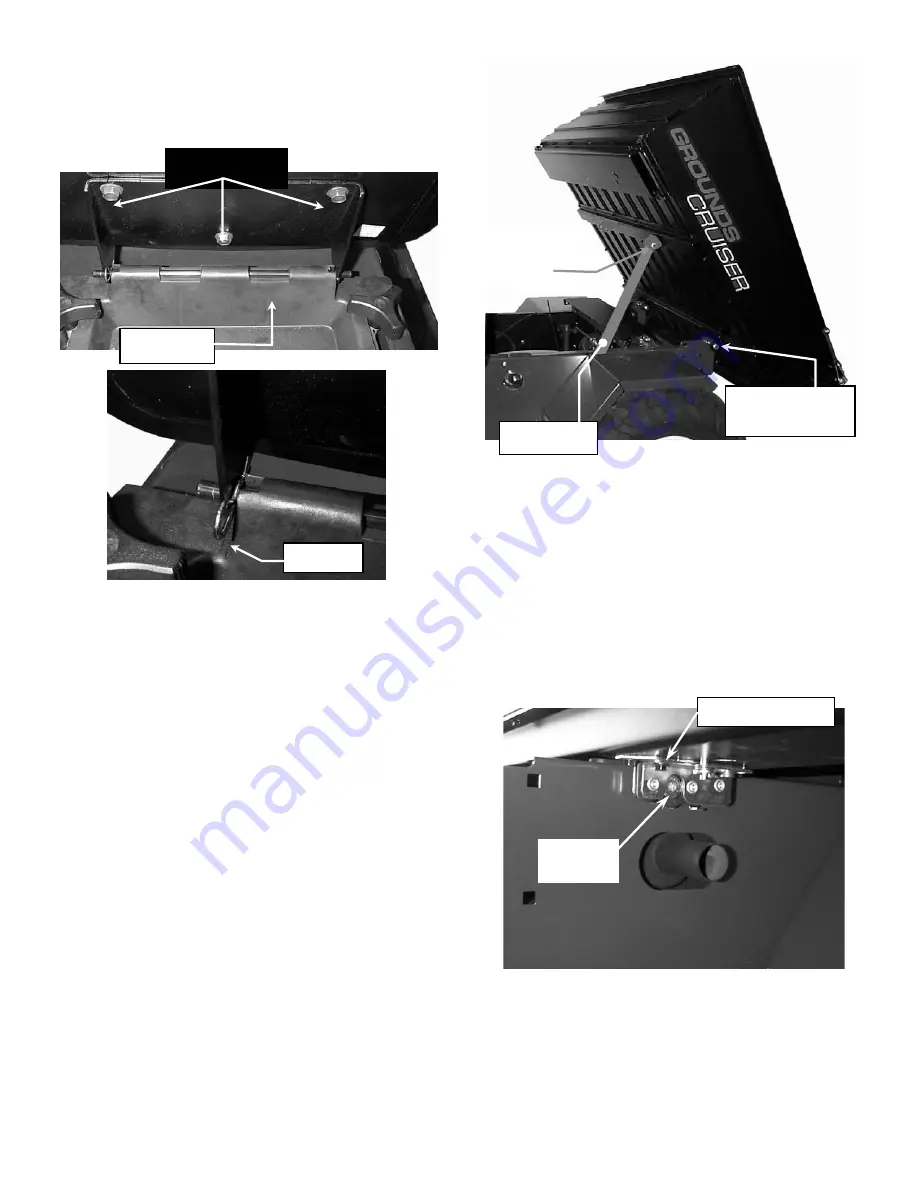

ATTACH CARGO BED

Attach bed to pivots at rear of frame. A prop rod is

provided to support an empty cargo bed only in a raised

position.

1. Align brackets on bottom rear of cargo bed with left

and right pivots located at rear of frame. See Figure

1.8.

2. Insert (1) 1/2-13 x 3 3/4” bolt into each left and right

pivot and secure with 1/2-13 NyLoc nuts. Tighten

securely.

3. Attach prop rod to bracket on bottom of cargo bed

using (1) 1/2-13 x 3” bolt and (1) 1/2-13 NyLoc nut.

Tighten to a snug rotating fit.

FIGURE 1.8

STEP 12

ALIGN LATCH IF NECCESARY

Lower the Cargo bed slowly until the latch contacts the

striker pin. The head of the striker pin should be inside

of the latch as shown in figure 1.9. If it is not aligned

correctly, loosen the bolts that attach the left and right

bed pivot brackets. Then, position the latch over the

striker pin as shown in figure 1.9 and re-tighten the bed

pivot bracket bolts.

FIGURE 1.9

(3) SEAT BOLTS

HINGE ROD

HAIRPIN

PROP ROD

1/2-13 X 3”

BOLT & 1/2-13

NYLOC NUT

1/2-13 X 3 3/4”

BOLT & 1/2-13

NYLOC NUT

LATCH ASSEMBLY

STRIKER

PIN