11

Section 2 - OPERATING INSTRUCTIONS

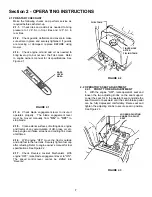

2.6. ROLLING TRACTOR WITH ENGINE OFF

2.6.1. Rolling Hydro Models

1.

With engine "OFF", move to rear of tractor.

2.

Pull the roll release control all the way out to

disengage the hydro transmission. See Figure 2.15.

FIGURE 2.15

3.

Move tractor to desired location.

4.

Push roll release control all the way in to engage

hydro transmission. See Figure 2.15.

5.

Set park brake.

NOTE:

The transmission will not propel the tractor if it is

left in the "ROLL" position.

WARNING

DO NOT disengage the hydro transmission and coast

down slopes. DO NOT use Roll Release Control to

disengage the hydro transmission unless machine

motion can be controlled and engine is off.

PUSH ROLL RELEASE

CONTROL ALL THE WAY

IN TO ENGAGE HYDRO

TRANSMISSION

ROLL RELEASE

CONTROL

ROLL RELEASE

CONTROL

PULL ROLL RELEASE

CONTROL ALL THE WAY

OUT TO DISENGAGE

HYDRO TRANSMISSION

Summary of Contents for LT180H33 IBV

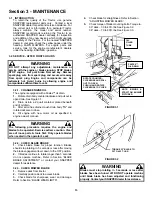

Page 39: ...39 PRIMARY MAINTENANCE...

Page 40: ...40 PRIMARY MAINTENANCE...

Page 41: ...41 PRIMARY MAINTENANCE...

Page 42: ...42 PRIMARY MAINTENANCE...