12

INSPECT AND CLEAN UNIT AND LA-

BELS

S

After each use, inspect complete unit for

loose or damaged parts. Clean the unit and

labels using a damp cloth with a mild deter-

gent.

S

Wipe off unit with a clean dry cloth.

CLEAN AIR FILTER

A dirty air filter decreases engine perform-

ance and increases fuel consumption and

harmful emissions. Always clean after every

5 hours of operation.

1.

Clean the cover and the area around it to

keep dirt from falling into the carburetor

chamber when the cover is removed.

2.

Remove parts by pressing button to re-

lease air filter cover.

NOTE:

To avoid creating a fire hazard or

producing harmful evaporative emissions, do

not clean filter in gasoline or other flammable

solvent.

3.

Wash the filter in soap and water.

4.

Allow filter to dry.

5.

Add a few drops of oil to the filter;

squeeze the filter to distribute oil.

6.

Replace parts.

Air Filter

Air Filter

Cover

Button

REPLACE SPARK PLUG

Replace the spark plug each year to ensure

the engine starts easier and runs better. Set

spark plug gap at

0.025 in. Ignition timing is fixed and

nonadjustable.

1.

Twist, then pull off spark plug boot.

2.

Remove spark plug from cylinder and

discard.

3.

Replace with Champion RCJ-6Y spark

plug and tighten securely with a 3/4 in.

socket wrench.

4.

Reinstall the spark plug boot.

SERVICE AND ADJUSTMENTS

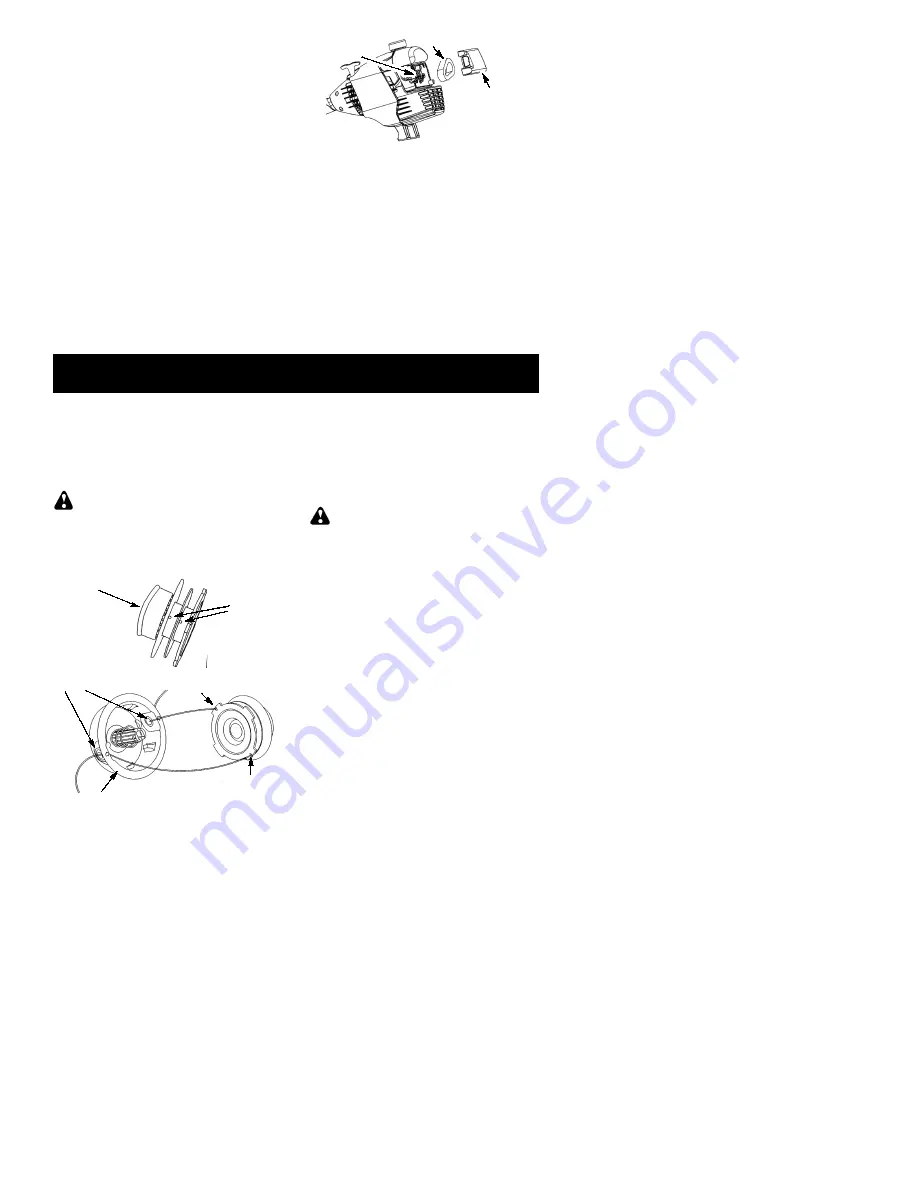

REPLACING THE LINE

1.

Remove spool by firmly pulling on tap

button.

2.

Clean entire surface of hub and spool.

3.

Replace with a pre-wound spool, or cut two

lengths of

12-1/2

feet of 0.080

!

(2 mm) di-

ameter

Snapper

t

/Weed Eater

r

brand line.

WARNING:

Never use wire, rope,

string, etc., which can break off and become a

dangerous missile.

4.

Insert ends of the lines about 1/2 inch (1

cm) into the small holes on the inside of

spool.

Small

Holes

Spool

Hub

Line in Notch

Line in Notch

Line exit holes

5.

Wind the line evenly and tightly onto the

spool. Wind in the direction of the arrows

found on the spool.

6.

Push the lines into the notches, leaving 3

to 5 inches (7 -- 12 cm) unwound.

7.

Insert the lines into the the exit holes in

the hub as shown in the illustration.

8.

Align the notches with the line exit holes.

9.

Push spool into hub until it snaps into

place.

10. Pull the lines extending outside of the hub

to release the lines from the notches.

CARBURETOR ADJUSTMENT

WARNING:

Keep others away when

making idle speed adjustments. The trimmer

head or any optional attachment will be spin-

ning during most of this procedure. Wear your

protective equipment and observe all safety

precautions. After making adjustments, the

trimmer head or any optional attachment

must not move/spin at idle speed.

The carburetor has been carefully set at the

factory. Adjustments may be necessary if you

notice any of the following conditions:

S

Engine will not idle when the throttle is

released.

S

The

trimmer

head

or

any

optional

attachment moves/spins at idle.

Make adjustments with the unit supported so

the cutting attachment is off the ground and

will not make contact with any object. Hold

the unit by hand while running and making ad-

justments. Keep all parts of your body away

from the cutting attachment and muffler.

Idle Speed Adjustment

Allow engine to idle. Adjust speed until engine

runs without trimmer head or any optional at-

tachment moving or spinning (idle too fast) or

engine stalling (idle speed too slow).

S

Turn idle

speed screw clockwise to

increase engine speed if engine stalls or

dies.

For Parts Call K&T 606-678-9623 or 606-561-4983

www.mymowerparts.com