7

ASSEMBLY

WARNING:

If received assembled,

repeat all steps to ensure your unit is properly

assembled and all fasteners are secure.

Examine parts for damage. Do not use dam-

aged parts.

NOTE:

If you need assistance or find parts

missing or damaged, call 1-800-554-6723.

It is normal for the fuel filter to rattle in the

empty fuel tank.

Finding fuel or oil residue on muffler is normal

due to carburetor adjustments and testing

done by the manufacturer.

INSTALLING TRIMMER ATTACH-

MENT

CAUTION:

When installing trimmer attach-

ment, place the unit on a flat surface for stabil-

ity.

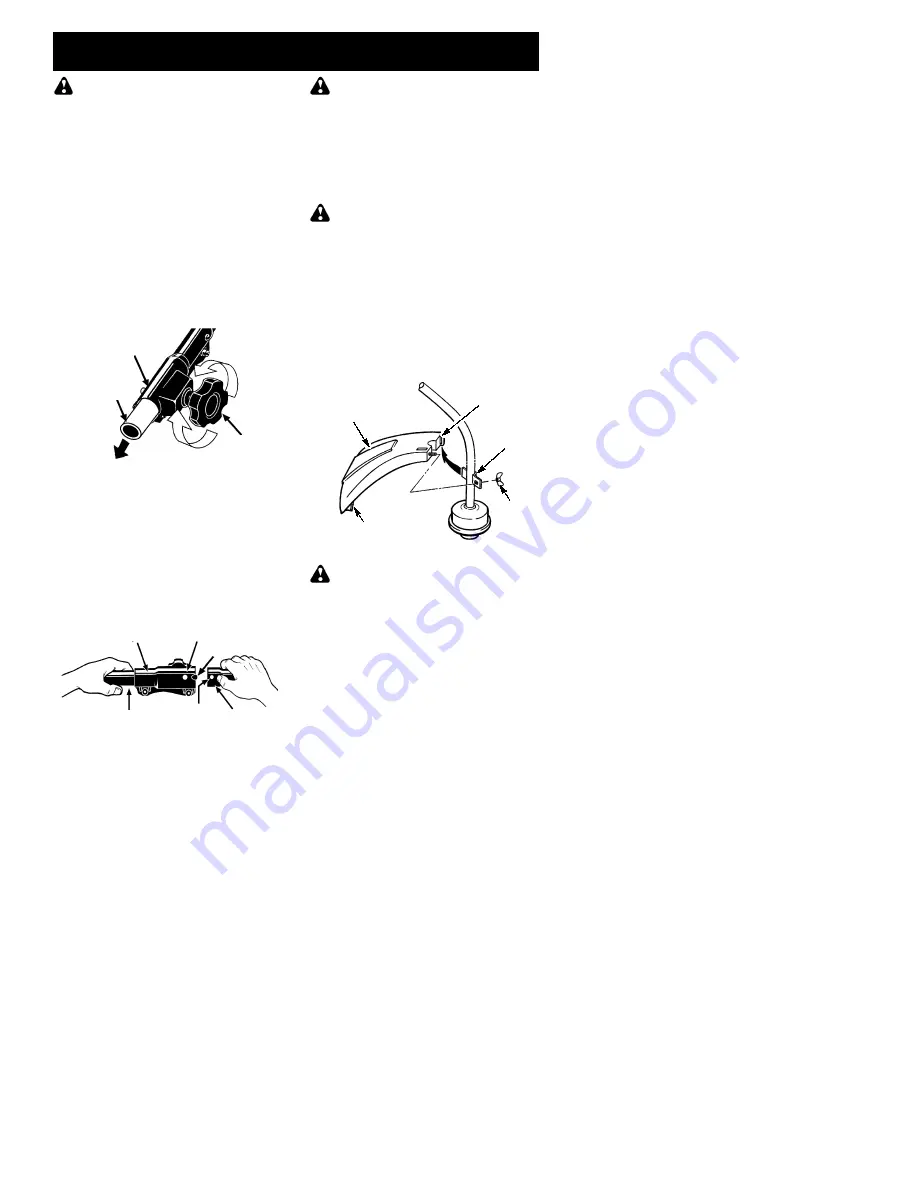

1.

Loosen the coupler by turning the knob

counterclockwise.

Coupler

Knob

LOOSEN

TIGHTEN

Shipping

protector

2.

Remove shipping protector from coupler.

3.

Remove the tube cap from the trimmer at-

tachment (if present).

4.

Position locking/release button of attach-

ment into guide recess of coupler.

5.

Push the attachment into the coupler until

the locking/release button snaps into the

primary hole.

6.

Before using the unit, tighten the knob se-

curely by turning clockwise.

Coupler

Primary Hole

Upper

Tube

Locking/

Release

Button

Lower

Attachment

Guide Recess

WARNING:

Make sure the locking/

release button is locked in the primary hole

and the knob is securely tightened before op-

erating the unit. All attachments are designed

to be used in the primary hole.

For optional

attachments,

see the AS-

SEMBLY section of the applicable attach-

ment instruction manual.

ATTACHING SHIELD

WARNING:

The shield must be prop-

erly installed. The shield provides partial protec-

tion from the risk of thrown objects to the opera-

tor and others and is equipped with a line limiter

blade which cuts excess line to the proper

length. The line limiter blade (on underside of

shield) is sharp and can cut you. For proper

orientation of shield, see KNOW YOUR TRIM-

MER illustration in OPERATION section.

1.

Remove wing nut from shield.

2.

Insert bracket into slot as shown.

3.

Pivot shield until bolt passes through hole

in bracket.

4.

Securely tighten wing nut onto bolt.

Slot

Shield

Wing

Nut

Bracket

Line Limiter Blade

ADJUSTING THE HANDLE

WARNING:

When adjusting the han-

dle, be sure it remains between the trigger

and the arrow on the safety label.

1.

Loosen wing nut on handle.

2.

Rotate the handle on the tube to an up-

right position; retighten wing nut.

For Parts Call K&T 606-678-9623 or 606-561-4983

www.mymowerparts.com