13

SECTION 3 – OPERATING INSTRUCTIONS

3.4 MACHINE MOVEMENT -

(Continued from previous page)

NOTE:

Releasing the Operator’s Presence Control

(OPC) while Transmission is in

GEAR

and/or Blades

are

ON

will ground the Ignition Circuit and cause the

Engine to

STOP

, allowing the

Machine to travel only a

few feet

before coming to a complete

STOP.

WARNING

During initial training time with machine, it is

advised that the operator(s) practice all mower

movements while operating the mower with the

transmission shift lever in no. 1 (first gear) travel

speed position and blade clutch switch in off

position! DO NOT make sharp turns at high speeds!

IMPORTANT: Always STOP machine movement and

lock traction levers before changing to a different

ground speed. Transmission damage could result if

ground speed is changed when machine is moving.

3.4.2. TURNING AND BRAKING.

WARNING

Machine should always be in forward motion before

attempting a turn. DO NOT attempt a turn from a

stopped position.

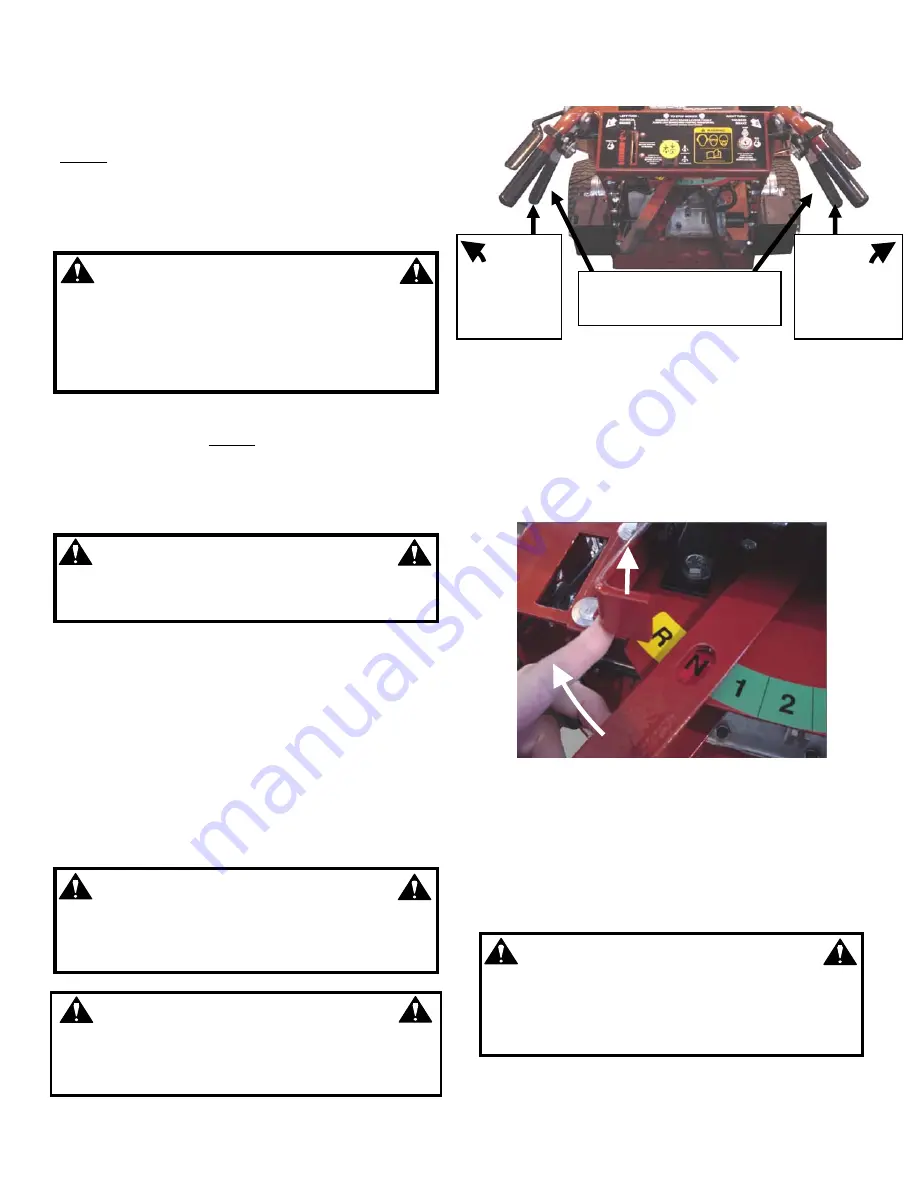

1. To Turn Left

, gradually squeeze left Traction Lever

against handle grip. See Figure 3.18. NOTE: The

harder the lever is squeezed, the sharper the turn

will be.

2. To Turn Right

, gradually squeeze right Traction

Lever against handle grip. See Figure 3.18.

NOTE: The harder the lever is squeezed, the

sharper the turn will be.

3. To Stop Machine Motion,

squeeze both Traction

Levers firmly against handle grips. See Figure

3.18. NOTE: The harder the levers are squeezed,

the harder the stop will be.

WARNING

Brakes require maintenance. Inspect for proper

operation before operating machine. Refer to

Section “ADJUSTMENTS, LOWER TRACTION ROD

ADJUSTMENT”.

WARNING

To avoid sudden and unexpected turning, both

Traction Levers must be depressed or released at

the same time when stopping or starting machine

motion.

FIGURE 3.18

3.4.3. REVERSE MOTION.

1.

With both Traction Levers locked, depress

Operator’s Presence Control (OPC) against handle.

See Figure 3.19.

2.

Lift up on reverse lockout lever, and move

transmission shift lever from the neutral (‘N’)

position into reverse (‘R’) gear. See Figure 3.19.

FIGURE 3.19

3.

Squeeze both Traction Levers firmly against handle

grips. Traction Locks are spring-loaded and will

snap back to the “Unlocked” position. Using

caution, slowly and simultaneously release

pressure on both Traction Levers. The machine

will begin to move in reverse.

WARNING

DO NOT operate blades in reverse. Stop blades.

LOOK and SEE behind and down for children, pets

and hazards before and while backing. Engine

speed must be set to SLOW before operating in

reverse.

(Continued on next page)

SQUEEZE

RIGHT

TRACTION

LEVER TO

TURN

RIGHT

SQUEEZE

LEFT

TRACTION

LEVER TO

TURN

LEFT

SQUEEZE BOTH TRACTION

LEVERS SIMULTANEOUSLY

TO STOP MACHINE

Summary of Contents for SGV13321KW

Page 27: ...27 PRIMARY MAINTENANCE...

Page 28: ...28 PRIMARY MAINTENANCE...

Page 29: ...29 PRIMARY MAINTENANCE...

Page 30: ...30 PRIMARY MAINTENANCE...

Page 31: ...31 NOTES...