8

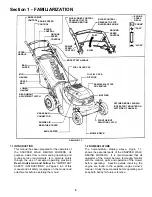

Section 2 - OPERATING INSTRUCTIONS

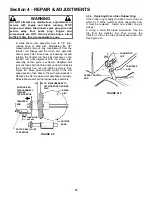

WARNING

DO NOT attempt any maintenance, adjustments or

service with engine and blade running. STOP

engine and blade. Disconnect spark plug wire and

secure away from spark plug. Engine and

components are HOT. Avoid serious burns, allow

sufficient time for all components to cool. Wear

heavy leather gloves when handling or working

around cutting blades. Blades are extremely sharp

and can cause severe injury.

2.6 RECYCLING OPERATION - OPTIONAL

ACCESSORY

Recycling operation requires optional accessory.

NOTE: For best recycling results, cut up to a maximum

of 1/3 of grass blade length and recycle ONLY when

grass is dry.

1. Set all wheels in the highest cutting position

(Notch 6).

2. Move engine speed control to “FAST” (Rabbit)

position.

3. Move ground speed control to slowest speed

setting.

4. Proceed mowing slowly. If grass is very dense,

lower each rear wheel latch one notch lower than

the front wheel latches to improve recycling

performance.

2.7 INSTALLATION of GRASS CATCHER

Position grass bag between handles. See Figure 2.8.

Install grass catcher by sliding connector over flange

of adapter. Attach grass bag hooks over middle

handle cross bar. See Figure 2.9.

FIGURE 2.8

FIGURE 2.9

WARNING

DO NOT operate without entire Grass Catcher or

guard in place. Grass Catcher components are

subject to deterioration during normal use. Inspect

frequently and replace worn or damaged

components immediately.

LOWER HANDLES

HANDLE

BAG CONNECTOR

ADAPTER

FLANGE

HOOK BAG

HANDLE OVER

LOWER HANDLES

SLIDE CONNECTOR

OVER END OF

ADAPTER FLANGE

Summary of Contents for VCP216012RV

Page 22: ...22 PRIMARY MAINTENANCE ...

Page 23: ...23 PRIMARY MAINTENANCE ...

Page 24: ...24 PRIMARY MAINTENANCE ...

Page 25: ...25 PRIMARY MAINTENANCE ...