Controls and Indicators

8

T40RT/T46JRT – 1430001

Battery Disconnect Switch

The battery disconnect is located at the right front of the

turntable (refer to Figure 2).

The battery disconnect removes electrical power from all

electrically controlled functions when in the off position.

Place the switch in the on position to electrically con-

nect the battery to the electrical system.

Caution

Only authorized personnel should operate the aerial

platform. Unqualified personnel may cause injury

to coworkers or property damage. Lock the battery

disconnect switch in the off position before leaving

the aerial platform unattended.

Lock the battery disconnect switch in the off position

to prevent unauthorized use of the aerial platform.

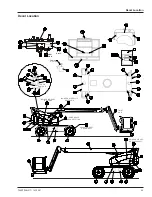

Lower Controls

The lower controls (refer to Figure 3) are located on the

left side of the turntable. Boom and platform functions

can be operated from the lower controls.

Emergency Stop Button

The emergency stop (refer to Figure 3) is a two-position,

red push button.

Push the button inward to disconnect power to all

control circuits.

Pull the button outward to restore power.

Controls Selector Switch

Use the controls switch (refer to Figure 3) to select be-

tween lower control and upper control operation.

Place the switch in the upward position to operate the

aerial platform from the upper controls.

Place the switch in the downward position for lower

control operation.

An alarm sounds when the switch is turned on to warn

others that the machine engine is being started.

Preheat Button

The preheat button (refer to Figure 3) is a two-position,

black push button. This button operates the glow plugs

to aid in starting the engine when the start switch is in

the on position.

When the engine is warmed up or the ambient tem-

perature is above 10°C (50°F), it is not necessary to

operate the glow plugs before starting the engine.

When the ambient temperature range is 10°C (50°F)

to -5°C (23°F), press and hold the preheat button for

five seconds before starting the engine.

•

•

•

•

•

•

•

•

When the ambient temperature is below -5°C (23°F),

press and hold the preheat button for ten seconds

before starting the engine.

Start Button

The start button (refer to Figure 3) works like an automo-

bile ignition switch.

Push the start button until the engine starts, then

release it to on.

If the engine dies, the control switch must be turned

to off before the engine can be restarted.

Ground Operation Switch

Hold the ground operation switch (refer to Figure 3) up-

ward continually to operate the machine from the lower

controls. The engine speed increases when the switch

is held upward. This switch is spring returned to the off

position.

Rotation Switch

The rotation switch (refer to Figure 3) is used to rotate the

turntable in a clockwise or counterclockwise direction. The

switch is spring returned to the center off position.

Hold the switch to the right to rotate the turntable

counterclockwise.

Hold the switch to the left to rotate the turntable

clockwise.

Boom Elevation Switch

The boom elevation switch (refer to Figure 3) is used

to raise or lower the main boom. The switch is spring

returned to the center off position.

Hold the switch upward to raise the main boom.

Hold the switch downward to lower the main boom.

Boom Extension Switch

The boom extension switch (refer to Figure 3) is used to

extend or retract the booms. The switch is spring returned

to the center off position.

Hold the switch to the right to extend the boom.

Hold the switch to the left to retract the boom.

Jib Articulation Switch – T46JRT

The jib switch (refer to Figure 3) is used to raise or lower

the jib. The switch is spring returned to the center off

position.

Hold the switch upward to raise the jib.

Hold the switch downward to lower the jib.

Platform Level Switch

The platform level switch (refer to Figure 3) is used to level

the platform floor with respect to the ground. The switch

is spring returned to the center off position.

•

•

•

•

•

•

•

•

•

•

•

Summary of Contents for 16GTRD

Page 2: ......