Maintenance

Section

4-20

A38E Work Platform

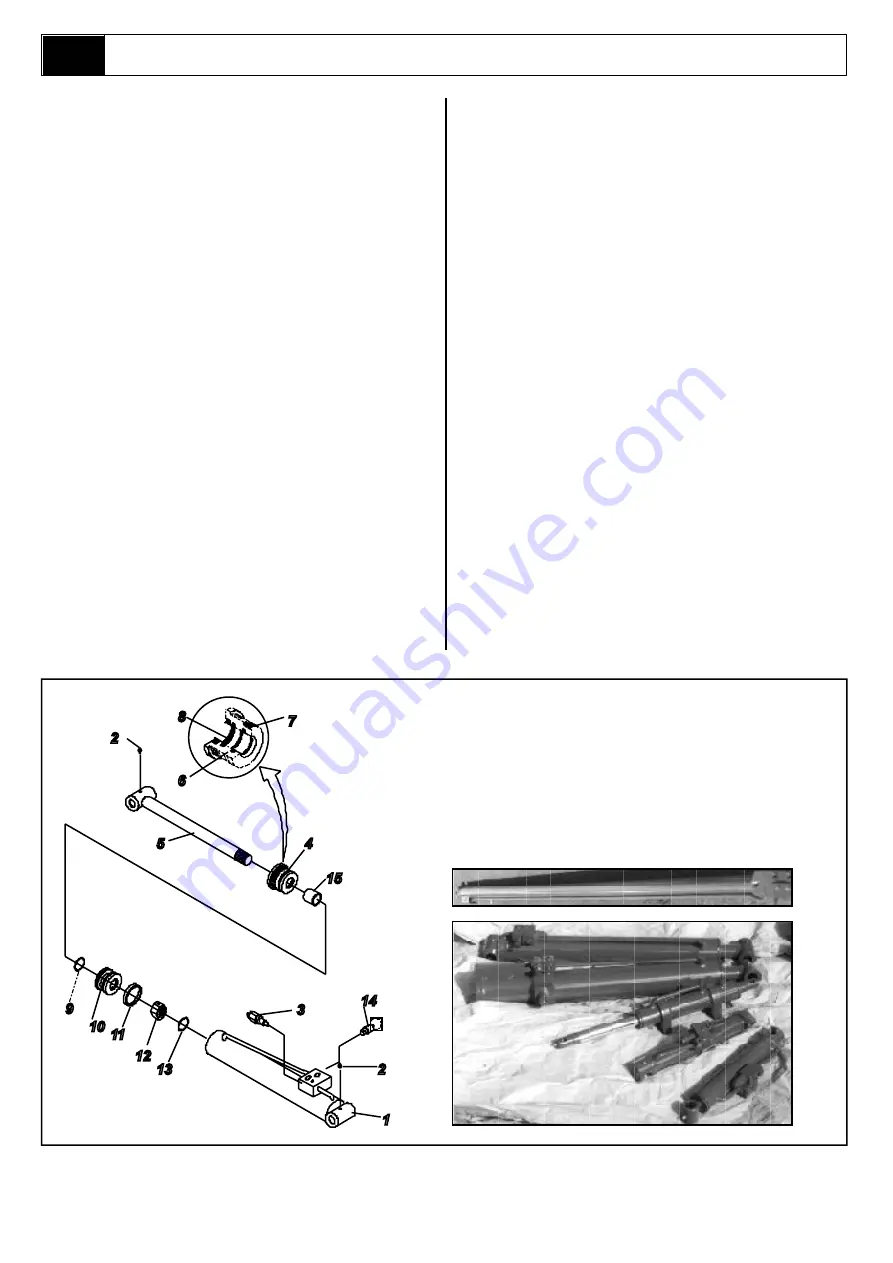

Figure 4-16: Hydraulic Cylinder Component Breakdown

2

7

8

13

12

11

10

15

4

5

6

3

14

2

1

1.

Cylinder Body

2.

Grease Nipple

3.

Overcentre Cartridge

4.

End Cap

5.

Rod And Pivot

6.

Rod Seal

7.

O-Ring

8.

Wiper

9.

Piston O-Ring

10. Piston Head

11. Piston Seal

12. Piston Locknut

13. Washer

14. Emergency Lowering

Valve

15. Spacer

4.14

with filtered compressed air.

2.

Check all threaded parts for stripped or

damaged threads.

3.

Check the bearing surfaces inside of the

headcap, outer edge surface of the piston,

inside of the cylinder barrel and the shaft for

signs of scoring, pits, excessive wear or

polishing. Scratches or pits deep enough to

catch a fingernail are unacceptable. Polishing is

a sign of uneven loading and if sufficiently

polished the affected parts should be replaced.

4.

Replace any parts or seals found to be

unserviceable.

REASSEMBLY/SEAL REPLACEMENT

Note: During seal replacement do not use sharp

edged tools to avoid cutting the seals, and allow

at least one hour for the seals to elastically

restore to their original shape before assembly.

1.

Lubricate and install new rod seal, rod wiper

and static seal on the headcap.

NOTE:

Multi-purpose lubricant should be used.

2.

Install a new piston seal on the piston.

3.

Install the headcap on the cylinder from the

piston end.

4.

Install the piston, piston nut and a new piston

static O-ring on the cylinder rod. Screw nut to

end of thread and secure with circlip.

9

Note: Diagram below shows a sample cylinder breakdown

for the Upper Lift Cylinder. Component Breakdowns of

the other cylinders are shown in the Illustrated Parts

Breakdown.

5.

Lubricate the piston seal and install the piston

and rod assembly in the barrel tube.

6.

Thread headcap onto barrel tube and hand

tighten, then turn 1/4 turn further.

7.

Install the lower cylinder Overcentre Valve.

INSTALLATION

NOTE:

Before installing Lift Cylinder check cylinder

pins, bearings and Trunnion Pivot for wear and

replace if necessary.

1.

Locate the Trunnion Pivot on the cylinder

and place the lift cylinder against the first post.

2.

Maintaining the Trunnion Pivot in place put the

first Allen Bolt in one turn. Repeat for all of the

bolts. When all bolts are in place tighten fully.

NOTE:

Take care in aligning the holes so that

the bolts can be made turn by hand. If holes are

not properly aligned the Trunnion Pivot will be

positioned incorrectly.

3.

Install rod end bearings (if removed).

4.

Lift rod end of cylinder into place and insert pin.

Install pin lock plate. Fix pin lock plate with bolt.

5.

Test with weight at rated platform load to check

system operation.

Summary of Contents for A38E

Page 1: ...A38E PARTS MANUAL S N 00715 AND AFTER ...

Page 3: ...SCHEMATICS 7 1 Appendix A Pages Index A Appendix B Parts Index B ...

Page 4: ...PARTS AND SERVICE AUG 2018 Serial Number 01 00715 Part number 514252 201 ...

Page 14: ...Page 6 A38E Work Platform Section 1 3 Introduction Specifications NOTES ...

Page 91: ...Maintenance 4 A38E ...

Page 98: ...A38E Maintenance 11 Major Repairs Date Part Number Part Description Repair Performed ...

Page 102: ...A38E Maintenance 15 ...

Page 106: ...Section 4 2 4 1 Notes ...

Page 140: ...Troubleshooting Section 5 6 A38E Work Platform 5 2 NOTES ...