Maintenance – 12 A38E

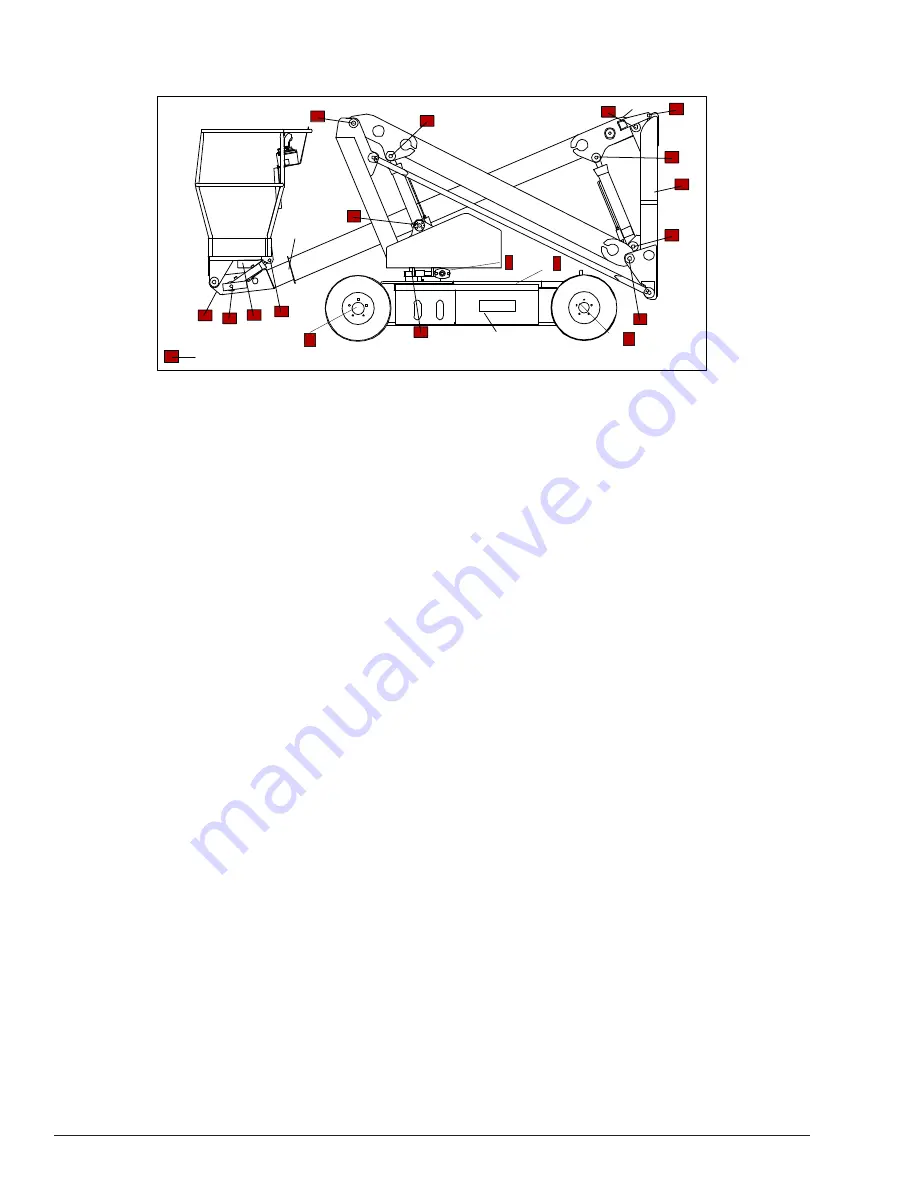

Lubrication Points

Lubrication

Specific lubricants as recommended by Snorkel, should

be used in maintaining the unit. If in doubt regarding

the use of lubricants other than those listed, contact

Snorkel Customer Service Department for evaluation

and recommendation.

Refer to the above lubrication illustration to locate com-

ponent item numbers.

Service all fittings as indicated on the Frequent Mainte

-

nance schedule and lubrication illustration. Wipe away all

excess lubricant from exposed surfaces. Over lubrication

can collect dirt and foreign matter which acts as an abra

-

sive. Lubrication of accessory equipment should be in

accordance with the manufacturer's recommendations.

Slew Ring

Slew Ring – Item 1. Pressure gun lubricate bearing at

recommended interval using lubricant as outlined in the

maintenance schedule. Rotate while lubricating. The

lubrication fittings are located on the turntable motor

below the ballast.

Rotation Gear Teeth and Pinion

Rotation gear teeth and pinion – Item 2. Gear teeth and

gear box pinion should be lubricated with Interflon LS1/2

gear lubricant. Grease Slew Ring evenly and sparingly

every 10 hours or 7 days.

DO NOT subject this area to powerwashing.

Tie Rods

Tie rods – Item 3. Lubricate at recommended interval us

-

ing lubricant as outlined in the maintenance schedule.

Pivot Pins

Pivot Pins – Item 7 Apply grease liberally to the Pivot

Pin and Pin Lock Plate locations using a brush or cloth.

Force as much Interflon LS1/2 grease as possible be

-

tween the Pins & Pin Lock Plates and the Weldments.

Wipe away all excess grease.

Gear Hubs

Gear hubs – Item 4. To check and fill Gear hubs:

1. Rotate the Gearbox into the horizontal position with

one of the filler/drain plug holes in the 3 O’ Clock

-

position and the other plug hole above it.

2. Remove plug bolts with drive ratchet and extension.

3. Fill until half full 0.9 Litres (0.23 Gallons) ,oil will

just start to trickle out the plug hole in the 3 O’Clock

position.

Note

Do not overfill gear hubs as they are not vented and need

air space for expansion of oil to prevent damage to hubs.

Platform Rotator

Platform Rotator – Item 5. Platform rotators will require

lubrication only if disassembled for repairs. Consult

factory for proper lubricant if replacement of platform

rotator is required.

Hydraulic Oil Reservoir(Tank)

Hydraulic oil reservoir – Item 6. With platform fully low

-

ered i.e. stowed, oil should be visible on the dipstick. If

the oil is NOT visible, fill the tank until oil is then visible

on the dipstick. DO NOT fill above the upper line on the

dipstick or when the platform is elevated.

Note: oil grades may vary depending on machine

specification. Contact Snorkel Product Support for

further advice.

The interior of the reservoir should be wiped out and

cleaned each time the hydraulic oil is changed. The

reservoir filler/breather cap and the filter housing should

be removed and cleaned with Kerosene, fuel oil, or other

solvent at this time.

It is absolutely necessary that only new, clean hydraulic

oil is added.

Note

If it becomes necessary to add or use an oil other than

the recommended fluid, it is important that it be compat

-

ible and equivalent to the factory fill. Local oil suppliers

Grease Fitting

1

2

3

4

4

5

6

7

7

7

7

7

7

7

7

7

7

8

8

9

Summary of Contents for A38E

Page 1: ...A38E PARTS MANUAL S N 00715 AND AFTER ...

Page 3: ...SCHEMATICS 7 1 Appendix A Pages Index A Appendix B Parts Index B ...

Page 4: ...PARTS AND SERVICE AUG 2018 Serial Number 01 00715 Part number 514252 201 ...

Page 14: ...Page 6 A38E Work Platform Section 1 3 Introduction Specifications NOTES ...

Page 91: ...Maintenance 4 A38E ...

Page 98: ...A38E Maintenance 11 Major Repairs Date Part Number Part Description Repair Performed ...

Page 102: ...A38E Maintenance 15 ...

Page 106: ...Section 4 2 4 1 Notes ...

Page 140: ...Troubleshooting Section 5 6 A38E Work Platform 5 2 NOTES ...