page 7 - 14

ATB 42/50 – 0161987

7. Daily Inspection and Maintenance

■

Placards and Decals

Look to see that all placards and decals are in place and legible. Replace any missing or illegible

placards or decals before placing the Snorkelift into service for the daily work shift.

Decal and placard kits for the ATB 42/50 are available from Snorkel dealers.

❑

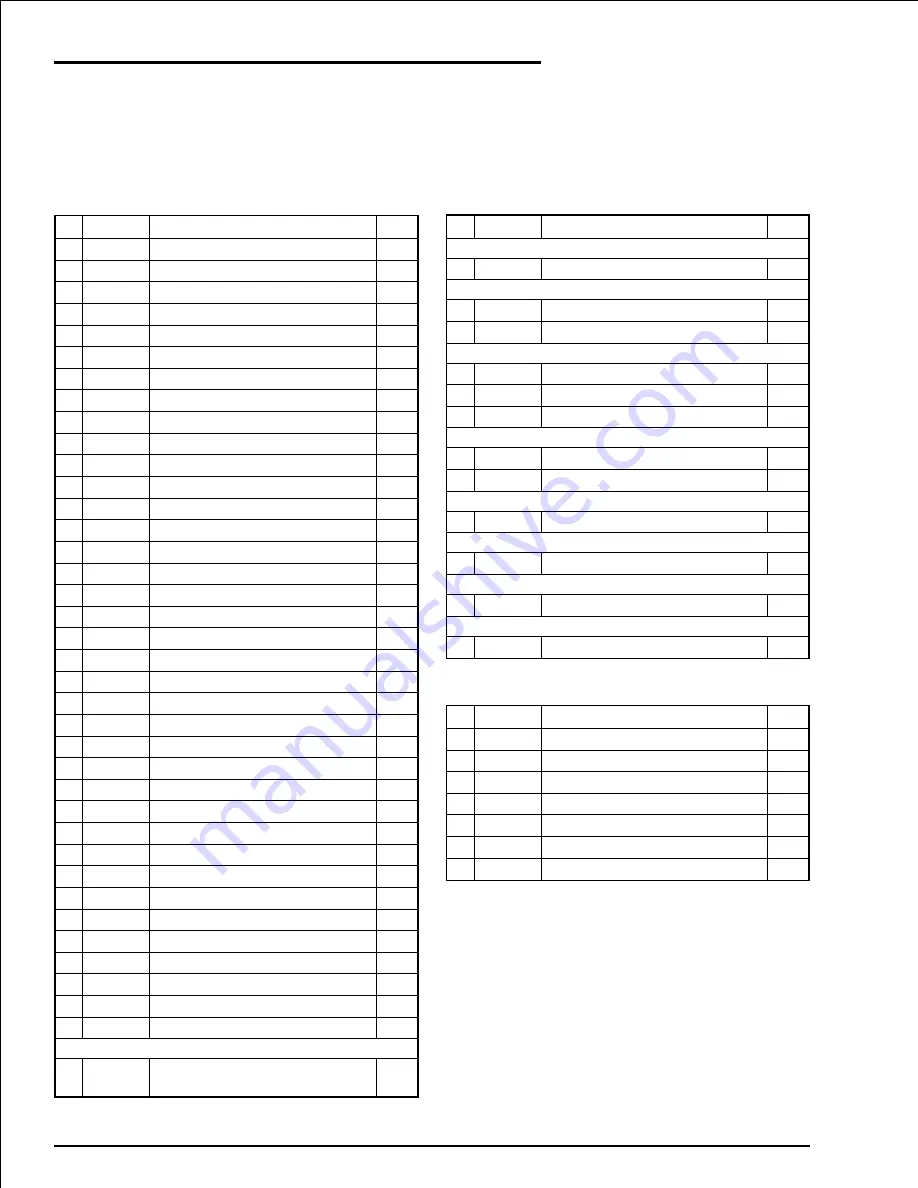

Standard Placards and Decals

No

Part No

Description

Req

1

0071927 Hydraulic oil

1

2

0070418 Snorkelift logo

2

3

0162337 Emergency lowering procedures

1

4

0070901 Caution serial number

1

5

0071425 Platform identification

1

6

0072277 Lug nut torque

4

7

0072531 Danger electrical hazard

1

8

0073224 Notice manual reorder

2

9

0074372 Engine RPM

1

10

0073492 Rotate while greasing

1

11

0073585 Made in USA

2

12

0074209 Pre-start instructions

1

13

0074311 Danger cylinder failure (1 per cyl)

10

14

0073491 Safe operating information

1

15

0150448 Attach fall restraint

2

16

0150452 Directional arrows forward/reverse

1

17

0150602 Danger descending boom

4

18

0073043 Manual reorder

1

19

0151410 Danger rotating engine parts

2

20

0151917 Directional arrows

1

21

0090589 Platform capacity 500 pounds

1

22

0161180 Snorkelift logo

2

23

0161205 Danger electrical hazards

2

24

7030003 Lube recommendations

1

25

0161329 Patents applied for

1

26

451986 Danger do not alter switch

1

27

0323899 Danger electrical hazard

1

28

0323897 Danger you must not operate

1

29

7030004 Omniquip logo

2

30

0161819 Emergency lowering procedures

1

31

0161937 Danger tipover hazard

1

32

0323896 Danger electrical hazard

2

33

0181562 ANSI standard

1

34

0181654 Danger inspect unit

1

35

0161402 Caution platform control box front

1

36

0161401 Danger platform control box top

1

37

0161212 Ground controls

1

Model identification

100

125

0161707

0161867

ATB 50 logo

ATB 42 logo

2

2

No

Part No

Description

Req

Diesel engine

150 0071926 Diesel fuel

1

Gasoline engine

175 0071925 Gasoline fuel

1

176 0074316 Caution governor damage

1

Dual fuel

200 0161667 Dual fuel system

1

201 0081441 Caution liquid withdrawal

1

202 0071925 Gasoline fuel

1

LP fuel only

225 0081441 Caution liquid withdrawal

1

226 0074316 Caution governor damage

1

Foam filled tires

250 0073298 Danger foam filled tires

2

Air filled tires

275 0070421 Tire pressure (1 per wheel)

4

4 wheel drive

300 0111390 4 x 4 logo

2

Crab steer

325 0161396 Crab steer

1

❑

Optional Placards and Decals

No

Part No

Description

Req

350 0161778 CE 5 station control valve

1

351 0161819E CE emergency lowering

1

352 0162194 CE mark logo

1

353 0162311 CE logo

1

375 0161699 Caution do not run engine

1

400 0181634 Engine block heater, Ford only

1

425 0150606 125 volt power to platform

1