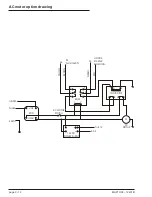

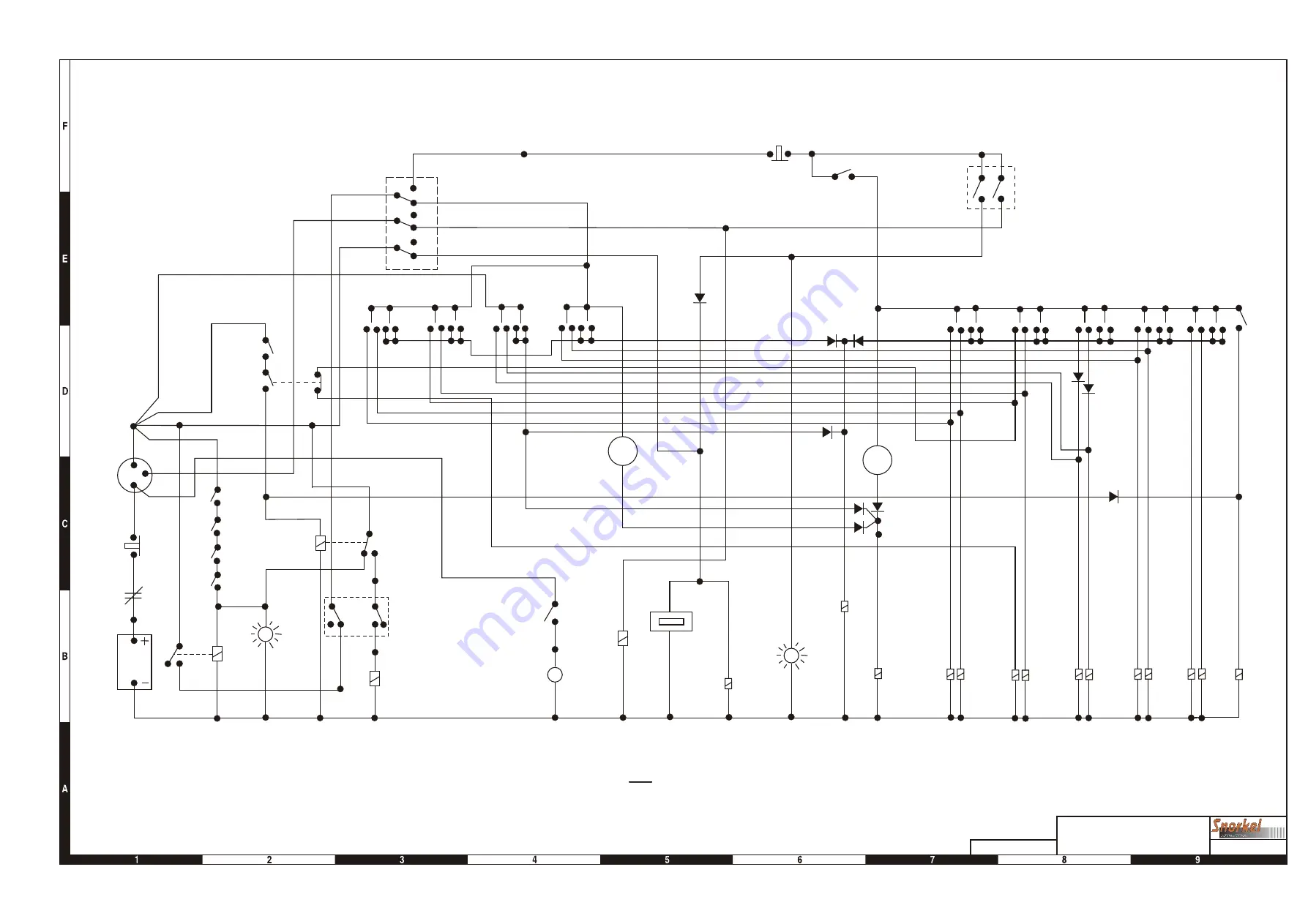

R1 = INTERLOCK RELAY

R2 = IGNITION RELAY

R3 = STABILISER RELAY

o

P/N 1650-010

o

P/N 1650-010

o

P/N 1650-010

Note:

(A1 - A12) and (B1 - B12) REPRESENT TERMINALS

ON TERMINAL STRIP IN THE LOWER CONTROL BOX

TITLE

Electrical Schematic for

Lombardini diesel option

Snorkel model MHP13/35

B1

A5

EMERG

STOP

FOOT

SW

LOWER

BOOM

UPPER

BOOM

JIB

BOOM

SLEW

BLEED

DOWN

B11

SPEED

CONTROL

RHEOSTAT

SPEED

CONTROL

RHEOSTAT

PROPORTIONAL

COIL

CONTROL

COIL

DOWN

DOWN

UP

UP

EXT

RET

RIGHT

LEFT

BLEED

DOWN

LIFT

ENABLE

LIGHT

LIFT

ENABLE

LIGHT

A8

FUEL

SOLENOID

HOUR

METER

A4

A7

R3

R3

R2

R2

87A

87

A12

A11

A1

A3

STAB

COIL

START

SOLENOID

STAB/

BOOM

SW

A10

STAB

SW

A9

R1

85

30

87

87A

86

A2

IGN

START

BATT

EMERG

STOP

CIRCUIT

BREAKER

BATTERY

LOWER

BOOM

SWITCH

UPPER

BOOM

SWITCH

P

G

PLATFORM / GROUND

SELECTOR SWITCH.

LOWER

BOOM

UPPER

BOOM

JIB

BOOM

SLEW

A6

B12

85

85

86

86

30

B9

B8

B7

B6

B5

B4

B3

B2

LEFT

RIGHT

ROTATOR

OPTION

IGN

BATT

START

30

87

Electrical schematic, Lombardini diesel

Page 3-5

Summary of Contents for MHP1335

Page 6: ......

Page 24: ...page 1 2 MHP13 35 12431B ...

Page 34: ......

Page 41: ......

Page 56: ......

Page 58: ...page 2 2 MHP13 35 12431B ...

Page 72: ......

Page 74: ...Page 3 4 Electrical schematic Auto stabiliser ...

Page 76: ......

Page 84: ......

Page 96: ......

Page 106: ......