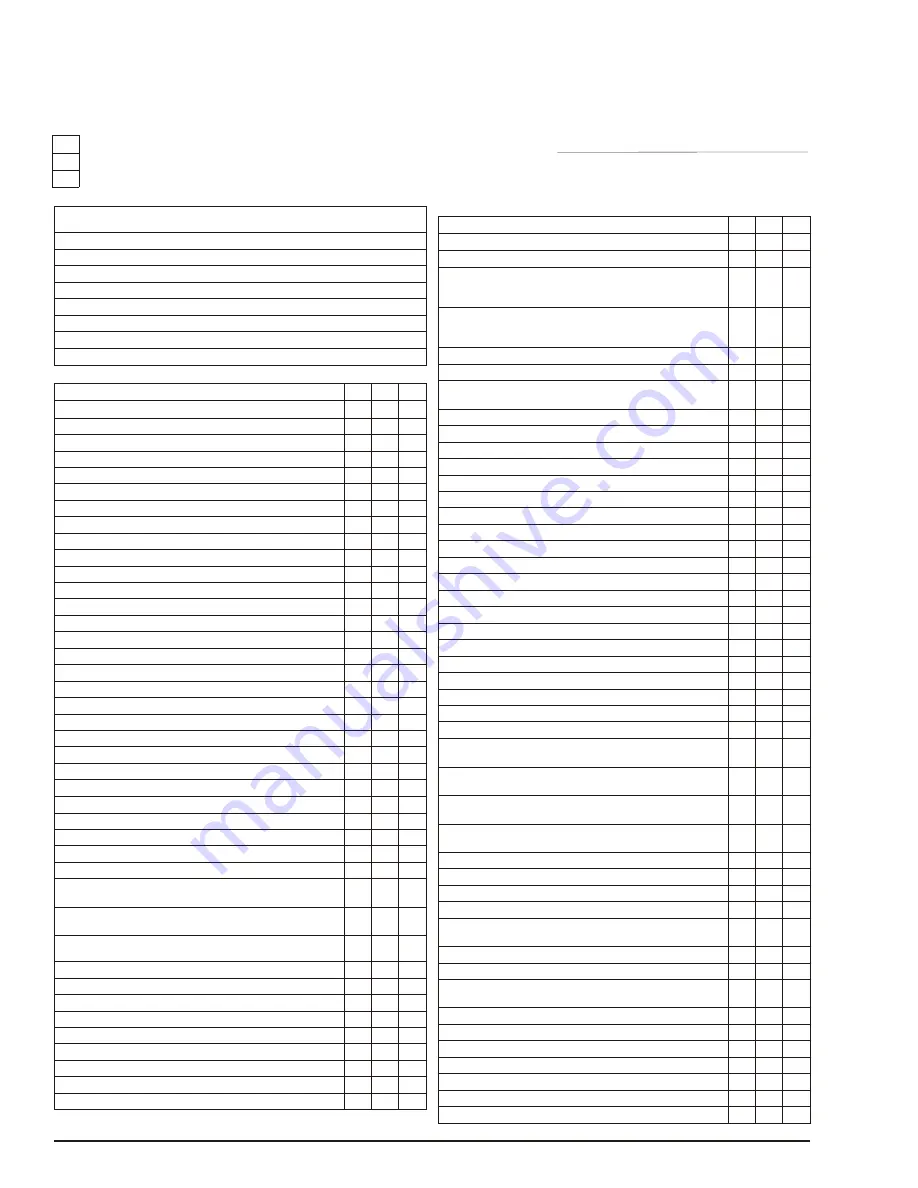

Inspection Procedures Codes

(1) Weld cracks, dents and/or rust

(2) Installation

(3) Leaks

(4) Operation

(5) Condition

(6) Tightness

(7) Residue buildup

(8) See placards and decals inspection chart

CHECK

OK

ü

X

BASEFRAME

Structural (1)

Steering cylinders (2,3,4,6)

Steering cylinder fasteners and linkage (2,4)

Tires and wheels (5)

Articulating axles, if so equipped (2,4,5)

Tray side covers (2,5,6)

Torque drive wheel lug nuts 90 - 100 ft. lbs. (2,6)

Torque steer wheel lug nuts 90 - 100 ft. lbs. (2,6)

Right drive motor(s) (3,6)

Left drive motor(s) (3,6)

Drive cut-out

Back-up horn (4)

Guides, rollers and slides (2,4,5)

Parking brake(s) (3,4)

Free wheeling valve (3,4)

Emergency lowering valve (3,4)

Lowering alarm (4)

Battery disconnect switch (4)

Lubrication points

Cords and wire assemblies (2,5,6)

Hydraulic tubes and hoses (3,5)

Decals and placards (2,8)

OUTRIGGERS AND CONTROLS

Right front outrigger (2,3,4)

Left front outrigger (2,3,4)

Right rear outrigger (2,3,4)

Left rear outrigger (2,3,4)

Platform elevated, outrigger controls

DO NOT WORK (4)

Outriggers lowered, platform elevated

DRIVE WILL NOT WORK (4)

SCISSOR ARM ASSEMBLY

Structural (1)

Scissor arm pivot pins (2,5)

Lift cylinders and valves (2,3,4)

Safety bar (2,4,5)

Hydraulic tubes and hoses (3,5)

Wires and electrical cables (2,5)

Decals and placards (2,8)

CHECK

OK

ü

X

BASE CONTROL STATION

Key switch, main power ON - OFF (4)

Selector switch base/platform controls -

BASE CONTROLS SELECTED

PLATFORM CONTROLS DO NOT WORK (4)

Selector switch base/platform controls -

PLATFORM CONTROLS SELECTED

BASE CONTROLS DO NOT WORK (4)

Toggle switch, platform UP - DOWN (4)

Key start switch (4)

Toggle switch, glow plug, timing light

diesel units only (4)

Fuel select switch GAS - LP FUEL (4)

Emergency stop switch (4)

Hour meter (4)

Circuit breaker reset (4)

Lowering alarm (4)

Engine kill alarm (4)

Low oil pressure alarm (4)

High temperature alarm (4)

Lift enable light (4)

PLATFORM

Structural (1)

Guardrails properly installed and fastened (2,5)

Platform entrance chain or gate (2,5)

Wires and electrical cables (2,5)

Decals and placards (2,8)

Correct operators manual in document holder

Roll out platform deck extension (2,4,5,8)

PLATFORM CONTROLS

Drive speed - platform elevated

SLOW DRIVE SPEED ONLY (4)

Drive speed - platform lowered

DRIVES FAST or SLOW (4)

Joystick control -

DRIVE/STEER and PROPORTIONAL LIFT (4)

Toggle type selector switch -

HIGH SPEED/HIGH TORQUE (4)

Toggle type selector switch - LIFT/DRIVE (4)

Low engine oil light (4)

Engine start/kill switch (4)

Lift enable light, if so equipped (4)

Raised platform drive enable light,

if so equipped (4)

Emergency stop button (4)

Joystick interlock switch (4)

Selector switch - ALTERNATOR/MACHINE

Units equipped with optional AC alternator (4)

page 14

Rev D

SR3370 & SR2770 – 13184B

Maintenance Information

■

Preventive inspection maintenance

90 day or 150 hour checklist

OK

OK - No Service Required

Serial Number

✔

Corrective Action Required

X

Corrected, (Record description of corrective action).

Summary of Contents for S2770BE

Page 2: ......

Page 10: ... Snorkel all rights reserved Printed in New Zealand ...

Page 44: ... Snorkel all rights reserved Printed in New Zealand ...

Page 62: ... Snorkel all rights reserved Printed in New Zealand ...

Page 66: ......

Page 83: ......

Page 87: ...TITLE Ground Box Sheet 1 Snorkel Models SR3370 SR2770 Ground box drawing sheet 1 Page 3 11 ...

Page 88: ...TITLE Ground Box Sheet 2 Snorkel Models SR3370 SR2770 Ground box drawing sheet 2 Page 3 12 ...

Page 89: ......

Page 98: ......

Page 99: ...Section 4 24Volt DC Option 24Volt DC Option SR3370 SR2770 13184B Rev D page 4 7 ...

Page 100: ...page 4 8 Rev D SR3370 SR2770 13184B ...

Page 114: ... ...

Page 115: ... ...

Page 116: ... ...

Page 117: ......

Page 118: ......

Page 119: ......

Page 124: ... ...

Page 125: ... ...

Page 126: ... ...

Page 127: ... ...

Page 128: ... ...

Page 129: ... ...

Page 130: ... ...

Page 131: ... ...

Page 132: ... ...

Page 133: ......