Introduction

S3219E/S3220E/S3226E/S4726E/S4732E – 1500842

5

Introduction

This manual covers the S3219E, S3220E, S3226E,

S4726E, and S4732E Aerial Work Platforms.

This manual must be stored on the machine at all times.

Read, understand and follow all safety rules and operating

instructions before attempting to operate the machine.

When contacting Snorkel for service or parts information,

be sure to include the MODEL and SERIAL NUMBERS

from the equipment nameplate. Should the nameplate

be missing, the SERIAL NUMBER is also stamped on

the front of the chassis.

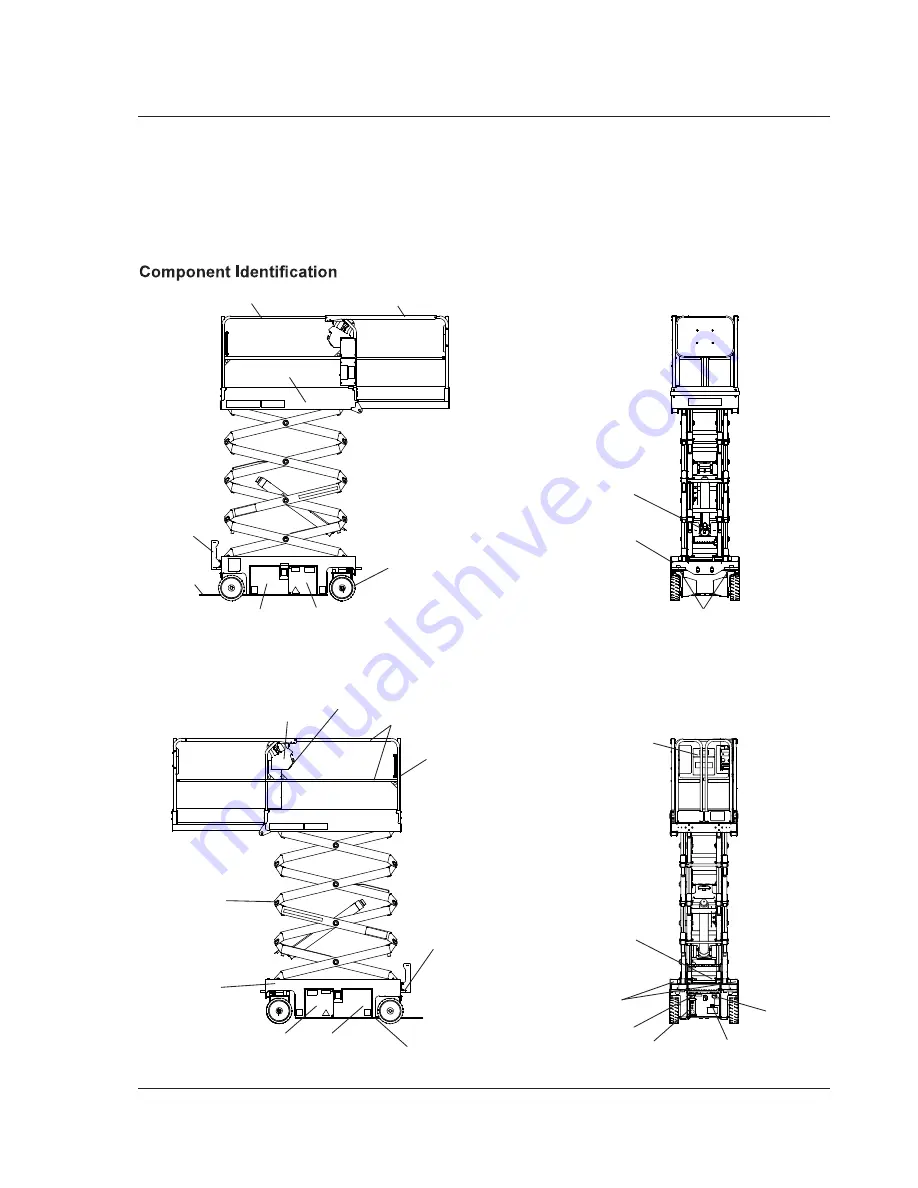

Scissors

Structure

Right Side

Platform

Guardrails

Left Side

Chassis

Upper

Controls

Entry

Doors

Platform Extension

Battery Tray

Drive and Steer

Wheels

Pothole

Protector Skid

Groundstrap

Tie-Down/Lifting

Lugs

Electrical

Power Outlet

Battery Tray

Hydraulic Tray

Pump/Reservoir/Fluid Filter

Control Valve Tray

Freewheeling Valve/Brake Release Valve

Hand Pump/Diagnostic Display

Entry

Step

Toeboards

Lower

Controls

Operator’s

Manual

Battery Charger

LED Charge Indicators

Tie-Down/Lifting Lugs

Rear

Front

Forklift

Pockets

Emergency Lowering

Lever – S3219E

Serial

Number

Power to Platform

Receptacle

Battery

Charger

Receptacle

Emergency Lowering

Handle – S3220E

S3226E, S4726E, S4732E