Lit. No. 85757, Rev. 01

11

November 15, 2018

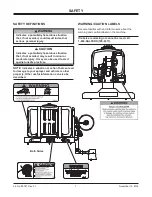

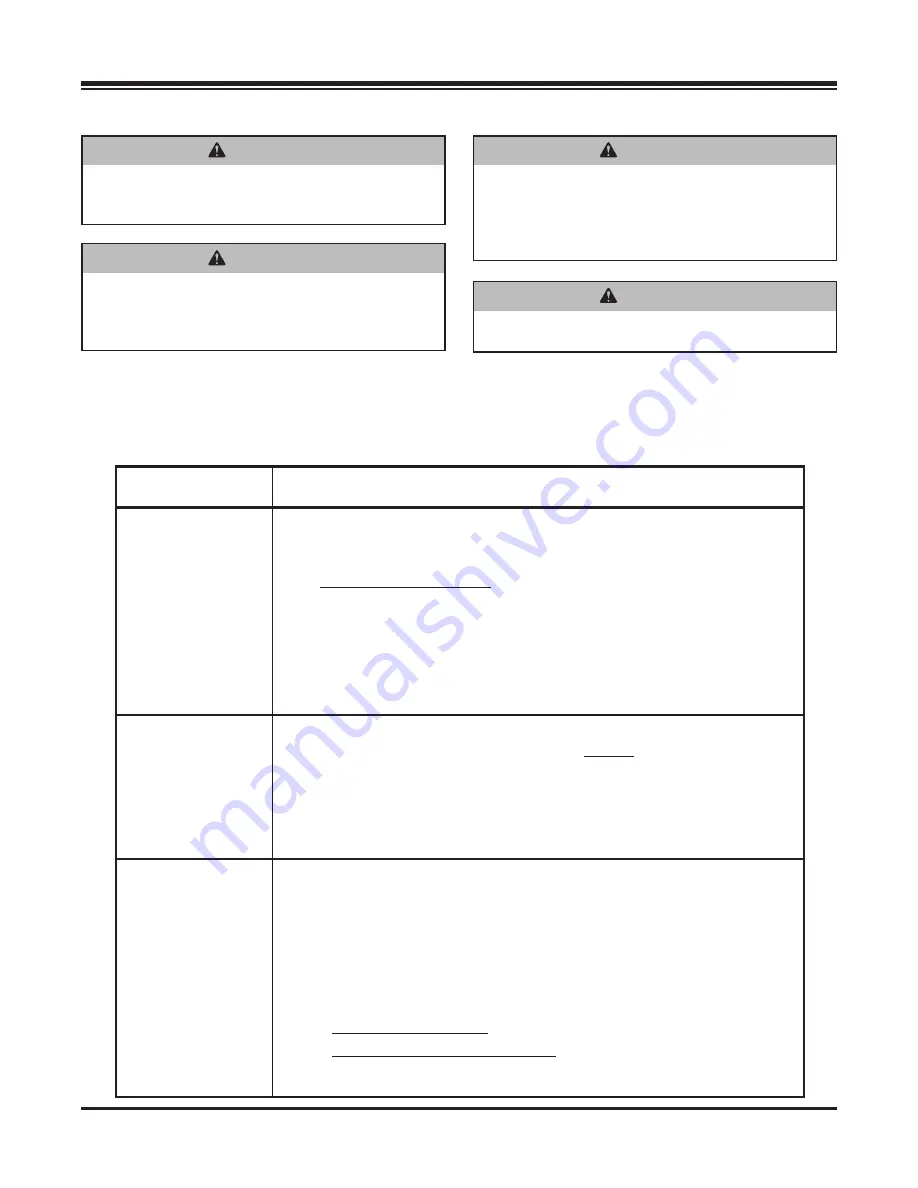

SAFETY

WARNING

Always shut vehicle OFF before attempting to

attach, detach, or service sprayer system.

WARNING

Overloading could result in an accident or

damage. Do not exceed GVWR or GAWR as

found on the driver-side cornerpost of vehicle.

CHEMICAL SAFETY

Immediate response is necessary in the event of sprayer leaks, bodily chemical contact, poisoning, or spills. See

instructions below:

Sprayer Leak

If the sprayer develops a leak, immediately stop spraying. Turn OFF power to

the sprayer and follow directions below, as applicable.

Bodily Chemical

Contact

Personal contamination can occur when chemicals splash, spill, or spray

directly onto a person.

1. Immediately follow First Aid instructions on chemical label.

General procedures include:

1a. Eyes – immediately

fl

ush with water.

1b. Skin – wash all contaminated skin surfaces with soap and water.

1c. Clothing – remove contaminated clothing. Dispose of heavily contaminated

clothing per chemical label instructions.

2. Seek medical advice if instructed on the label or if the victim experiences

symptoms of harmful effects. Bring the chemical label for reference.

Poisoning by

Ingestion or

Inhalation

In case of poisoning from ingestion or inhalation:

If the victim has collapsed or is not breathing, call 911. Otherwise:

1. If you are the victim, immediately seek assistance from nearby personnel, because

you may become incapacitated.

2. Immediately follow First Aid instructions on chemical label.

3. Call a poison control center for further advice. In the U.S., call 1-800-222-1222.

Have the chemical label available for reference.

Chemical Spills

Chemical spills must quickly be contained and properly cleaned up.

Refer to the chemical label for any speci

fi

c clean-up instructions.

General procedures include:

1. Control the spill by stopping the source of the spill.

2. Contain the spill so that it does not spread and get into water sources.

3. Clean up the spill immediately.

4. Seek additional advice from:

– Chemical manufacturer: See chemical label for contact information.

– State pesticide regulatory agency: In the U.S., call the National

Pesticide Information Center at 1-800-858-7378 for assistance in

contacting your state's agency.

WARNING

Never exceed 45 mph (72 km/h) when loaded

sprayer system is attached to vehicle. Braking

distances may be increased and handling

characteristics may be impaired at speeds

above 45 mph (72 km/h).

WARNING

Never operate equipment when under the

in

fl

uence of alcohol, drugs, or medication

that might alter your judgment and/or reaction

time.

Summary of Contents for Accuspray VSS-1000-1

Page 2: ......

Page 4: ...Lit No 85757 Rev 01 4 November 15 2018...

Page 6: ...Lit No 85757 Rev 01 6 November 15 2018...