Lit. No. 85757, Rev. 01

16

November 15, 2018

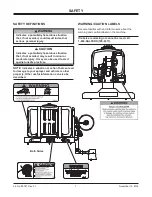

OPERATING INSTRUCTIONS

WARNING

Always make sure personnel are clear of

areas of danger when using equipment.

Maintain 60' distance from all bystanders

when operating the sprayer system.

WARNING

Vehicle handling and characteristics will

change with the unit installed. Avoid any

sudden steering maneuvers, starts, or stops

that could create sloshing and instability.

WARNING

Before operating the sprayer, verify that all

safety guards are in place.

WARNING

Unit must be strapped down and locked into

position before operating or transporting.

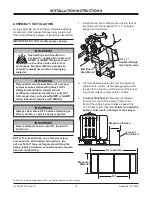

CAUTION

Starting the motor with no antifreeze

will damage the seal in the pump. Check

antifreeze levels before starting.

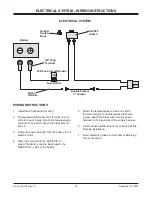

DURING OPERATION

• Read and follow each chemical label's instructions

and warnings.

• Avoid inhaling, ingesting, or coming into contact

with any chemicals.

• Know applicable licensing and regulatory

requirements for the chemical(s) you plan to use.

• Know emergency procedures before handling

chemicals. Carefully review the Chemical Safety

section. Also see First Aid instructions on the

chemical label.

• Wear protective clothing, eye protection, and

chemical-resistant gloves when

fi

lling, using,

and cleaning the sprayer. Wear additional

protective gear, such as a face mask or apron, as

recommended on the chemical label.

• Exercise extra caution around children and pets.

Keep sprayer and spray materials away from them

at all times.

• Do not mix or pour chemicals in an enclosed,

unventilated area.

• Do not use

fl

ammable or corrosive chemicals in

the sprayer.

• Flush the sprayer before switching chemicals in

order to prevent dangerous chemical interactions.

• Do not allow anyone younger than 16 years of age

to operate sprayer.

CAUTION

Never operate equipment when under the

in

fl

uence of alcohol, drugs, or medication

that might alter your judgment and/or reaction

time.

Summary of Contents for Accuspray VSS-1000-1

Page 2: ......

Page 4: ...Lit No 85757 Rev 01 4 November 15 2018...

Page 6: ...Lit No 85757 Rev 01 6 November 15 2018...