Lit. No. 85757, Rev. 01

17

November 15, 2018

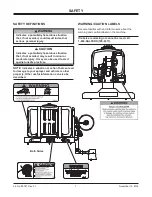

BEFORE SPRAYING

• Inspect and prepare sprayer before each use as

directed in this manual.

• Do not start sprayer until ready to spray in order to

avoid unintentional spray release.

• Wear additional personal protective equipment

if you will be spraying overhead. Wear

chemical-resistant head and neck protection,

full-face mask (or half-face mask with sealed

goggles), and consider using a respirator.

• Do not spray when wind speed exceeds 4 mph in

order to minimize spray drift.

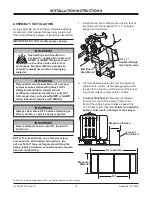

ADDING BRINE/LIQUID

Fill the tank to the desired level by

fi

lling through

the tank lid. Use the markings on the tank for

volume reference. During operation, if liquid is not

coming out of the tank, check the Maintenance

and Troubleshooting sections of this manual.

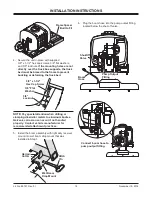

SPRAYER OPERATION

1. Be sure that the pump switch is in the "OFF" position.

2. Fill the sprayer with liquid through the port on the

top of the tank.

3. Select the desired application method by turning

the valve handle to the appropriate position:

• OPEN for the spray boom

• CLOSED for the spray wand

4. When ready to spray, turn the pump switch to the

"ON" position.

5. If using the spray wand, point the wand in the

desired direction and pull the trigger. Hold the

trigger until spraying is concluded.

6. When done spraying, be sure to turn the pump

switch to the "OFF" position.

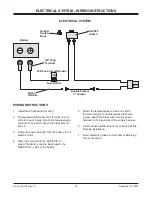

DURING SPRAYING

• Do not eat, drink, smoke, rub your eyes, or touch your

bare skin while handling chemicals and/or spraying.

• Never point the spray wand at people or animals.

• Always hold the spray wand

fi

rmly when using it to

spray at higher pressures in order to prevent wand

from whipping. Keep good footing and balance at all

times.

• Do not spray near open

fl

ames or sources of heat.

• Exercise extra caution when spraying near areas

accessible to children and/or pets.

• Clean up spills immediately per instructions on the

chemical label.

• Turn OFF vehicle and set brake or block wheels,

turn sprayer OFF, and relieve system pressure

before leaving sprayer unattended.

• See Troubleshooting section of this manual before

attempting any repairs. Wear personal protective

equipment and follow safety instructions.

OPERATING INSTRUCTIONS

Summary of Contents for Accuspray VSS-1000-1

Page 2: ......

Page 4: ...Lit No 85757 Rev 01 4 November 15 2018...

Page 6: ...Lit No 85757 Rev 01 6 November 15 2018...