Lit. No. 85757, Rev. 01

21

November 15, 2018

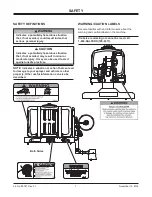

PERIODIC MAINTENANCE

• When servicing, you may need to close the

shut-off valve and/or the return valve, to prevent

stored brine from exiting the holding tank.

• Wash unit after each use to prevent material

build-up and corrosion.

• Use dielectric grease on all electrical connections

to prevent corrosion each time power or signal

plugs are disconnected.

• Paint or oil all bare metal surfaces as needed.

• Inspect unit for defects: broken, worn, or bent

parts, and similar.

• Inspect all tubing, hoses, and harnesses for

cracks and leaks.

• Clean the brine

fi

lter as needed. Close the shut-off

valve and access the

fi

lter by unscrewing the top

cap, then unscrewing the

fi

lter cover.

• Retighten bolts, screws, and other connections

after

fi

rst use and as needed.

END OF SEASON AND STORAGE

• Before long periods of storage,

fl

ush out the

tank, pumping system, and boom to remove salt

build-up and prevent corrosion.

• Do not leave unused material in the unit for a

prolonged period of time.

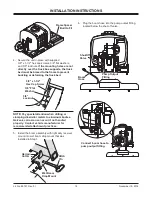

NOZZLE MAINTENANCE

Remove nozzles by pushing in and rotating the nozzle

cap counterclockwise and clean as necessary.

When reassembling nozzles, make sure that the

nozzle holes are in line with the boom. Failure to

align the nozzle holes will result in inconsistent brine

application.

MAINTENANCE

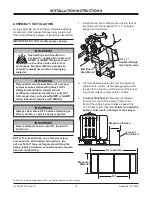

NOTE: To prevent leaks, use a thread-sealing

compound on all threaded connections. Do

not use Te

fl

on

®

tape, as fragments will clog the

spray nozzles. Clamped connections may require

periodic retightening

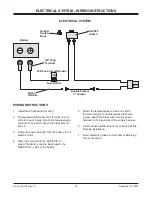

CLEAN OUT

1. Disconnect nozzle assemblies at rear of vehicle at

quick-disconnect point.

2. Make yourself a hose with matching male

quick-disconnect to hook up at quick-disconnect

point.

3. Install hose at quick-disconnect point and put the

other end in the storage tank.

4. Turn ON pump and run it until the tank is empty.

5. Add water and RV antifreeze; mix into tank.

6. Reinstall quick-disconnect from nozzle

assemblies.

7. Run pump until clear liquid is running out of each

nozzle.

Te

fl

on

®

is a registered trademark of E. I. du Pont de Nemours and Company.

WARNING

Inspect the unit periodically for defects. Parts

that are broken, missing, or worn out must be

replaced immediately. Do not alter any part of

the unit without prior written permission from

the manufacturer.

WARNING

Always shut vehicle OFF before attempting to

attach, detach, or service sprayer system.

WARNING

Do not operate a machine in need of

maintenance.

Summary of Contents for Accuspray VSS-1000-1

Page 2: ......

Page 4: ...Lit No 85757 Rev 01 4 November 15 2018...

Page 6: ...Lit No 85757 Rev 01 6 November 15 2018...