Lit. No. 86834, Rev. 00

21

November 15, 2018

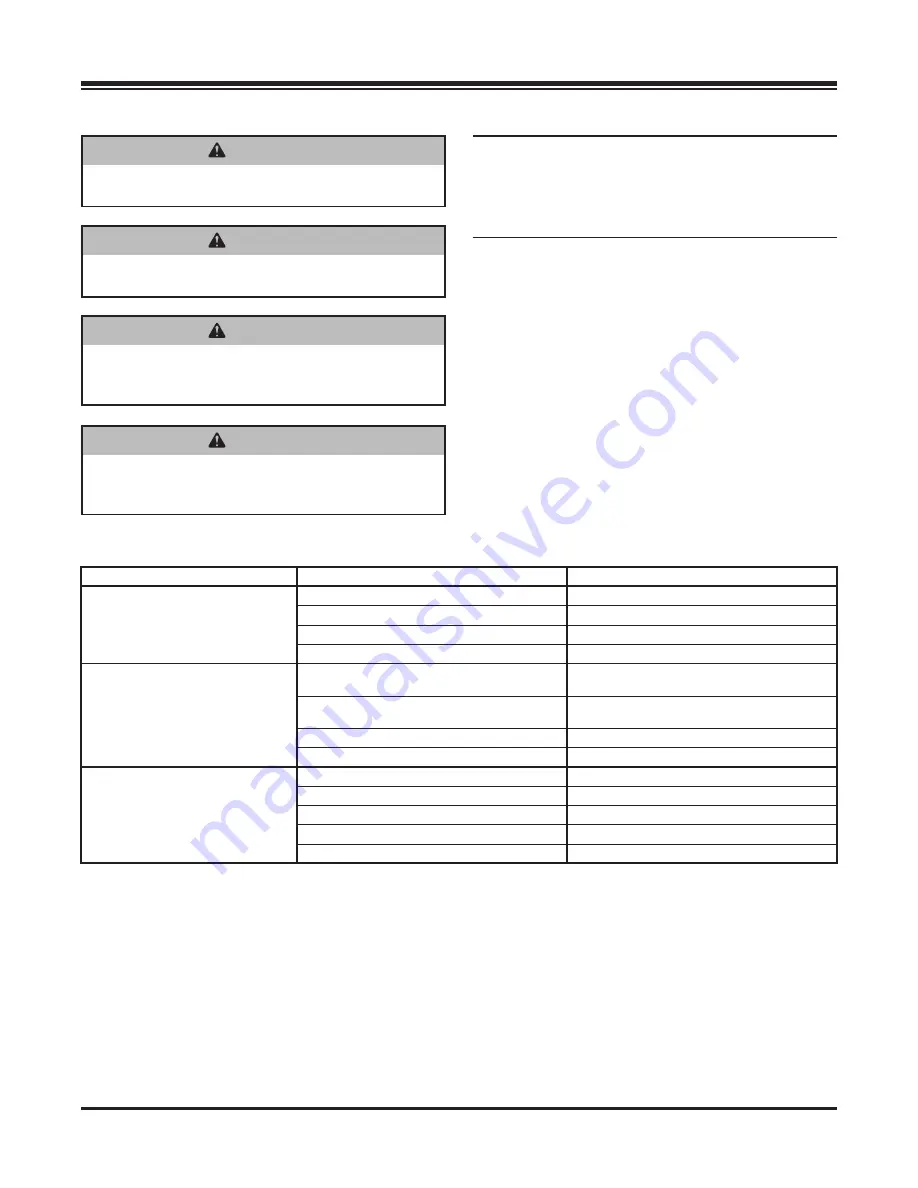

TROUBLESHOOTING

NOTE: To prevent leaks, use a thread-sealing

compound on all threaded connections. Do

not use Te

fl

on

®

tape, as fragments will clog the

spray nozzles. Clamped connections may require

periodic retightening.

Problem

Possible Cause

Suggested Solution

Pump doesn't run.

Loose electrical connections.

Check all connections.

Blown fuse.

Replace fuse.

Pump seized.

Replace pump.

Dead (or dying) battery.

Charge or replace battery.

Control shut down.

Poor electrical connections.

Clean or replace connectors. Use dielectric

grease.

Electrical short.

Check electrical connections. Check for

bare wires.

Dead (or dying) battery.

Charge or replace battery.

Control failure.

Replace control.

Liquid not spraying.

Empty tank.

Fill tank.

Full strainer.

Clean or replace element.

Pump not running.

Refer to Problem 1 ("Pump doesn't run").

Dead (or dying) battery.

Charge or replace battery.

Obstructed nozzle.

Remove and clean.

Te

fl

on

®

is a registered trademark of E. I. du Pont de Nemours and Company.

WARNING

Always shut vehicle OFF before attempting to

attach, detach, or service sprayer system.

WARNING

Do not operate a machine in need of

maintenance.

Whenever service is necessary, your local

SnowEx

®

dealer knows your de-icing system best.

Take your Accuspray™ De-Icing System to your local

dealer for any maintenance or service needs on your

unit. If this is not possible, the Troubleshooting Guide

below may assist you in identifying the problem.

Preliminary Checks:

• Make sure that all electrical connections are tight

and clean.

• Make sure that nothing is obstructing the nozzles.

WARNING

Read all warning instructions and safety

messages before servicing the sprayer

system.

WARNING

Always wear safety glasses with side shields

when servicing sprayer system. Failure to do

this could result in serious injury to the eyes.