© Trynex International 2009 L1102

5 — 36

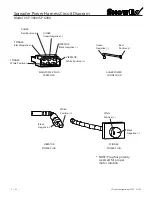

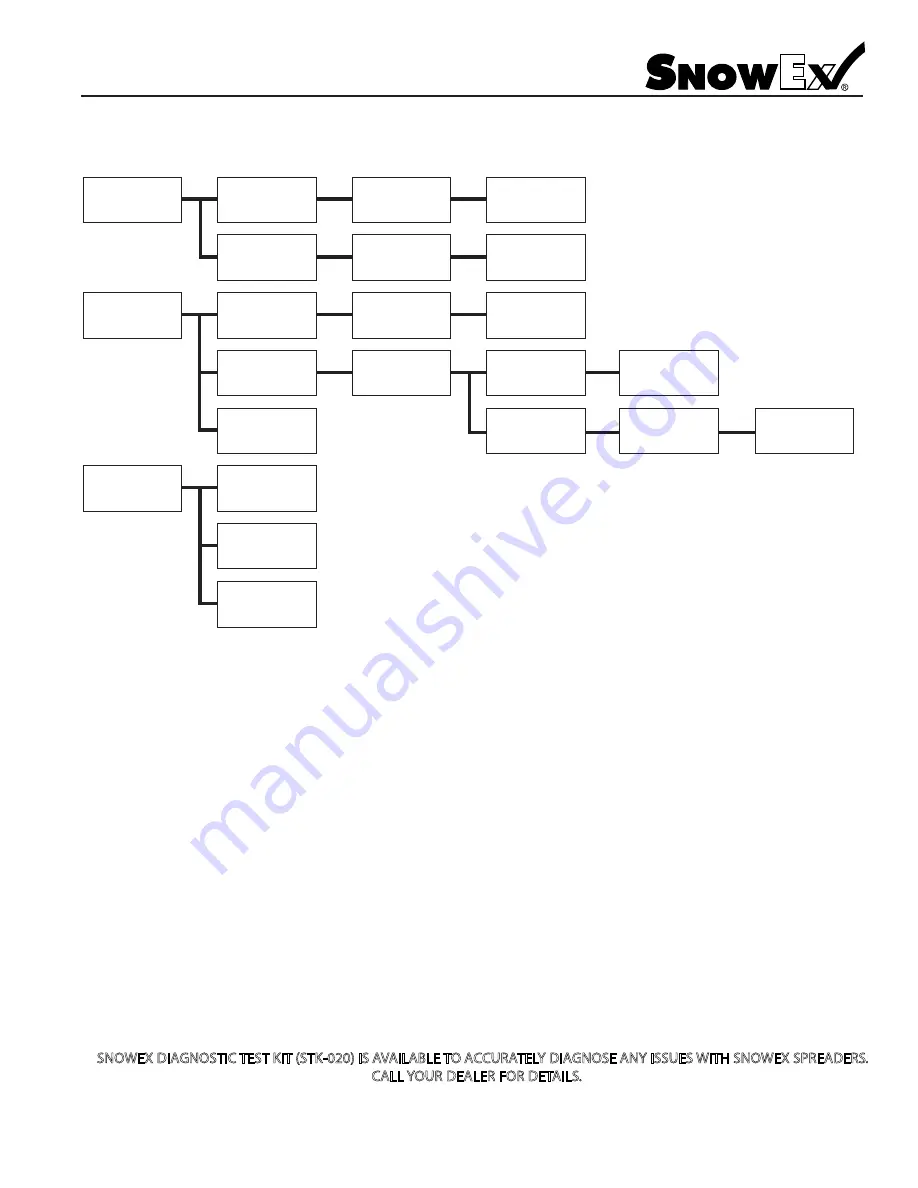

Troubleshooting Material Flow

Model # SP-3000/SP-6000

NOTE: Optional Optimum Flow Kit Available, To Increase Material Flow

* Spreader capable of speading most granular bulk material, including

coarse 50/50 salt/sand mix with Optimum Flow Kit.

MATERIAL

FREE FLOWS

MATERIAL ISSUE

CHECK BAFFLE

LENGTH

18" CORRECT

MATERIAL ISSUE

CHECK BAFFLE

POSITION

SHOULD TOUCH HOPPER

ON 3 SIDES

MATERIAL

DOES NOT FLOW

MATERIAL ISSUE

AUGER RUNS

PROPER DIRECTION

AUGER RUNS

BACKWARDS

REPLACE VEHICLE

HARNESS

CHECK CONNECTIONS

AT AUGER MOTOR

FOR REVERSE POLARITY

POLARITY CORRECT

REPLACE SPREADER

HARNESS

MATERIAL

OBSTRUCTION

REMOVE

OBSTRUCTION

AUGER RUNS

BACKWARDS

RUN 12 VOLT TO

AUGER CIRCUIT ON

SPREADER POWER CORD

TURN ON

VIBRATOR

SLOW

MATERIAL

FLOW

TURN ON

VIBRATOR

INCREASE

AUGER SPEED

MATERIAL ISSUE

SNOWEX DIAGNOSTIC TEST KIT (STK-020) IS AVAILABLE TO ACCURATELY DIAGNOSE ANY ISSUES WITH SNOWEX SPREADERS.

CALL YOUR DEALER FOR DETAILS.

Summary of Contents for Vee Pro 3000

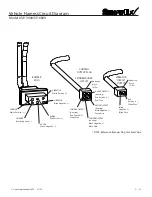

Page 8: ...Trynex International 2009 L1102 5 8 Side and Bottom View Model SP 3000...

Page 9: ...Trynex International 2009 L1102 5 9 Side and Bottom View Model SP 6000...

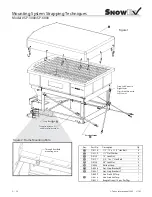

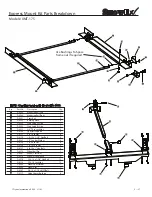

Page 11: ...Trynex International 2009 L1102 5 11 Main Assembly Parts Breakdown Model SP 3000...

Page 13: ...Trynex International 2009 L1102 5 13 Main Assembly Parts Breakdown Model SP 6000...

Page 18: ...Trynex International 2009 L1102 5 18 Assembly View Model SP 3000 SP 6000...

Page 39: ...THIS PAGE INTENTIONALLY LEFT BLANK Trynex International 2009 L1102 5 39...

Page 40: ...THIS PAGE INTENTIONALLY LEFT BLANK Trynex International 2009 L1102 5 40...

Page 41: ...THIS PAGE INTENTIONALLY LEFT BLANK Trynex International 2009 L1102 5 41...