© Trynex International 2009 L1102

5 — 37

Spreader Maintenance

•

WARNING –

When servicing is necessary, perform it in a protected area. Do not use power tools in rain or snow because

of danger of electrical shock or injury. Keep area well lighted. Use proper tools. Keep the area of service clean to help

avod accidents.

•

WARNING –

Disconnect electricity to spreader before servicing.

•

CAUTION –

The controller is a solid state electronic unit and is not serviceable. Any attempt to service will void warranty.

•

CAUTION –

There are no serviceable parts in the motor/transmission assembly. Any attempt to service will void warranty.

•

CAUTION –

When replacing parts use only original manufacturer’s parts. Failure to do so will void warranty.

•

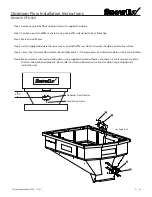

Use diaelectric grease on all electrical connections to prevent corrosion at the beginning and end of the season and each

time plugs are disconnected.

•

Gently wash unit after each use to prevent material build-up and corrosion.

•

CAUTION – When pressure washing motor enclosure area stay at least 36'' away from all electrical items.

•

Paint or oil all bare metal surfaces at the end of the season.

•

Apply small amount of light oil to latches as needed.

•

If motor cover is removed for any reason, use silicone sealant to ensure weather proofing of enclosure.

•

Grease bearings after every 20 hours’ use.

•

After first use, tighten all nuts and bolts on spreader and mount.

•

WARNING: Never remove spreader with material in hopper.

•

ATTENTION: Store control in cool dry place during the off season.

•

CAUTION – Spinner motor is not designed for continuous duty. Allow motor to cool between long cycle times.

Model # SP-3000/SP-6000

Summary of Contents for Vee Pro 3000

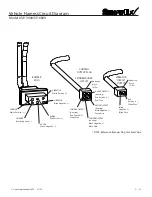

Page 8: ...Trynex International 2009 L1102 5 8 Side and Bottom View Model SP 3000...

Page 9: ...Trynex International 2009 L1102 5 9 Side and Bottom View Model SP 6000...

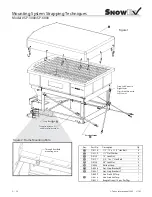

Page 11: ...Trynex International 2009 L1102 5 11 Main Assembly Parts Breakdown Model SP 3000...

Page 13: ...Trynex International 2009 L1102 5 13 Main Assembly Parts Breakdown Model SP 6000...

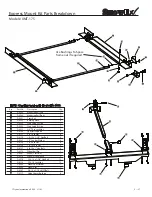

Page 18: ...Trynex International 2009 L1102 5 18 Assembly View Model SP 3000 SP 6000...

Page 39: ...THIS PAGE INTENTIONALLY LEFT BLANK Trynex International 2009 L1102 5 39...

Page 40: ...THIS PAGE INTENTIONALLY LEFT BLANK Trynex International 2009 L1102 5 40...

Page 41: ...THIS PAGE INTENTIONALLY LEFT BLANK Trynex International 2009 L1102 5 41...