31

EN

ATyS / ATyS r - 541630C - SOCOMEC

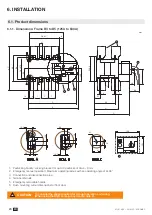

7. CONNECTIONS

7.1. Power circuits

7.1.1. Cable or bar connections

2A3 2A5 2A7

2A1

2A4 2A6 2A8

2A2

1A3 1A5 1A7

1A1

1A4 1A6 1A8

1A2

Recommended tightening torque:

• M6: 4,5 N.m

• M8: 8,3 N.m

• M10: 20 N.m

• M12: 40 N.m

Maximumtighteningtorque:

• M6: 5,4 N.m

• M8: 13 N.m

• M10: 26 N.m

• M12: 45 N.m

CAUTION

For B3 (8kV)

- Terminations must respect a minimum of 8 mm clearance from live parts to parts

intended to be earthed and between poles

For B4,5,6,7,8 (12kV)

- Terminations must respect a minimum of 14 mm clearance from live parts to

parts intended to be earthed and between poles

7.1.2. Power connection terminals

125A TO 630A

Refertosection“Productdimensions”,page20forpowerconnectionterminalsupto630A.

33

8.5

8.5

50

33

10

ø 9

ø 15

svr_077_a_1_x_cat

800A TO 1000A

16 x 11

60

28.5

15.75

15.75

28.5

15

svr_078_b_1_x_cat

1250A

15

5

5

12.5

25

25

30

30

45

45

90

ø12.5

1600A TO 3200A

Summary of Contents for ATyS r

Page 3: ...3 EN ATyS ATyS r 541630C SOCOMEC ...

Page 41: ...41 EN ATyS ATyS r 541630C SOCOMEC 9 CHARACTERISTICS ...

Page 51: ......