!

!

3.3 Coupling on and uncoupling from the excavator

3.3.1. Coupling

1) Place the hammer horizontally with its axe parallel to the excavator boom on the ground in

a stable position.

2) Remove the clamps holding the bucket and take the bucket away.

- Stop the hydraulic system of the excavator

.

- Take the caps out of the system and in case they have no taps, collect the hydraulic oil in a

container, then fix the hoses connecting the hammer to the system (see scheme “Hammer

hoses connection” par. 3.2) and open the oil taps if present.

- Stock away the caps of the flexible hoses, which will be used again during the next

uncoupling of the hammer.

3.3.2. Uncoupling

- Place the hammer horizontally on the ground in a safe area.

- Stall the hydraulic system of the excavator.

- Close the hoses' flow if possible.

- Disconnect the hoses and close up the ends of the flexible hoses in order to prevent oil

leaking and dirt intake.

- Remove the connecting rod pin.

- Remove the boom pin.

- After unblocking the hydraulic system, take the excavator boom out of the adapting plate.

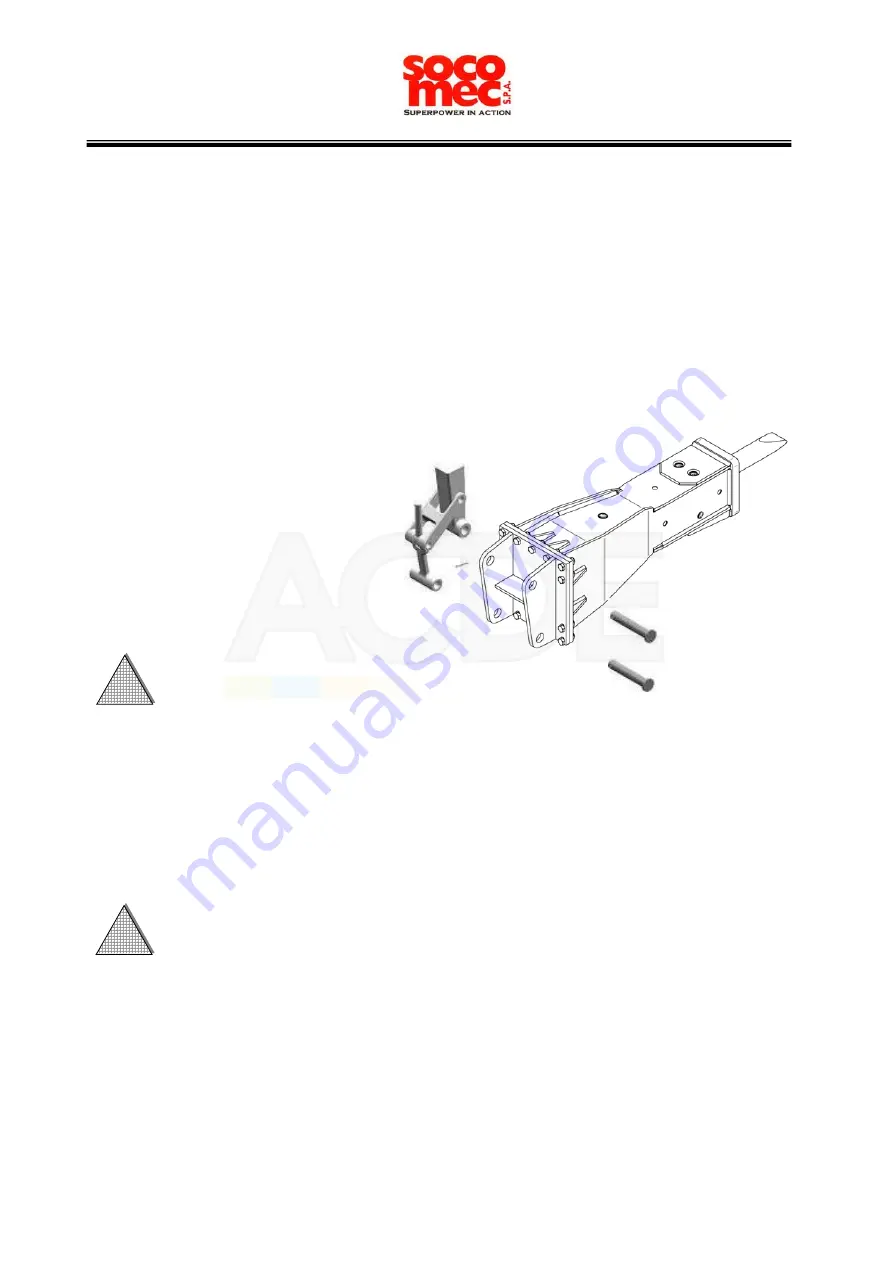

Insert the boom end in the middle of the

handles of the adapting plate.

- Line up the hole of the excavator boom

with the equivalent one on the adapting

plate, insert the first pin and fix its

clamps.

- Then line up the hole of the connecting

rod with the second hole on the adapting

plate, insert the second pin and fix well

its clamp.

TRANSPORT AND INSTALLATION

13

Page

of 48

3

Nederland B.V.

Summary of Contents for MDO 1600 TS

Page 34: ...44 39 41 43 45 36 35 38 40 42 46 37 STROKE CHANGER 34 Page of 48 10 Nederland B V ...

Page 40: ...101 96 98 100 99 97 DISTRIBUTOR GROUP 40 Page of 48 13 Nederland B V ...

Page 42: ...107 104 106 101 105 109 108 103 102 ACCUMULATOR GROUP 42 Page of 48 14 Nederland B V ...

Page 46: ...129 132 125 134 127 128 126 133 130 133 131 GREASING SYSTEM 46 Page of 48 16 Nederland B V ...