1

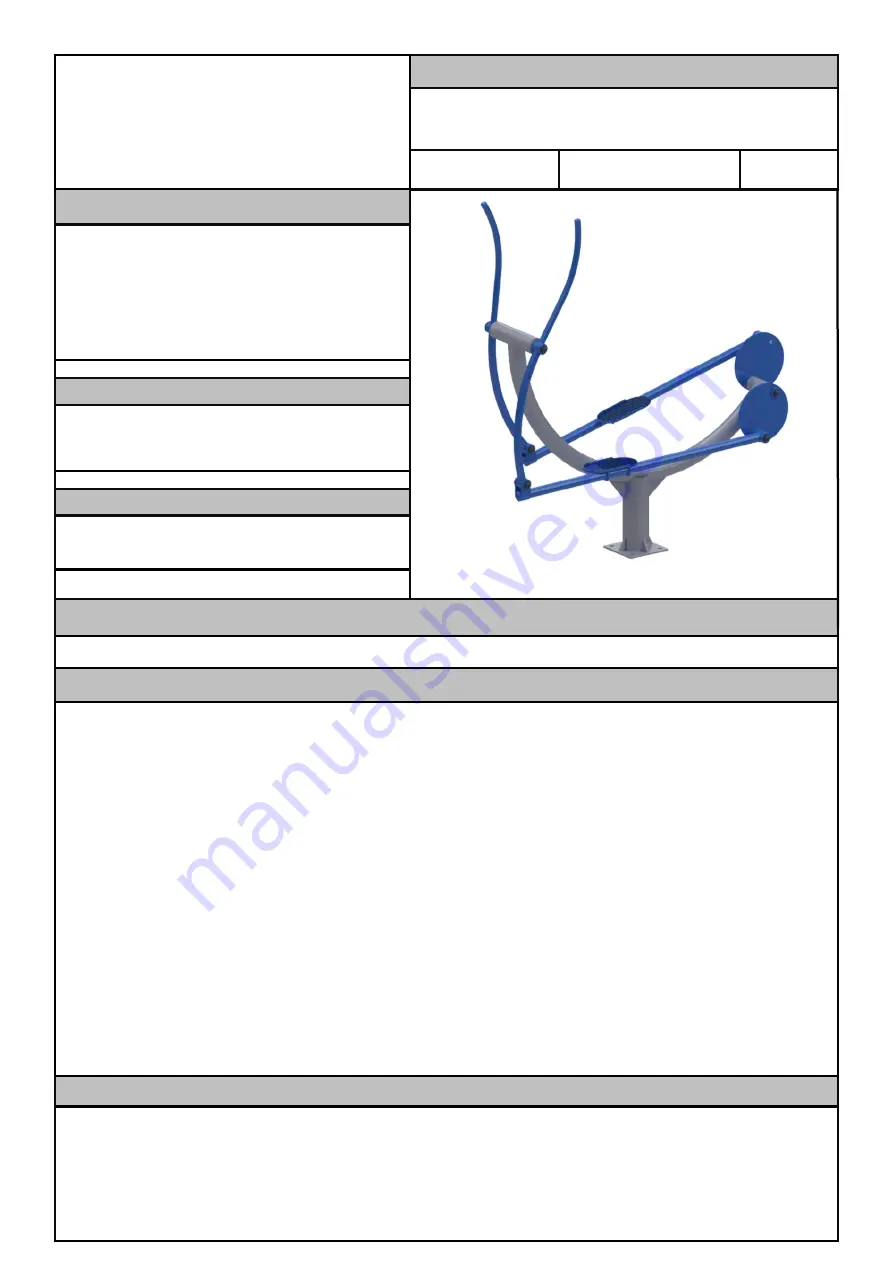

DESCRIPTION

Steel structure Ø90

Powder coated

CONFORM

European norm

NF EN 16630

PRODUCT SHEET

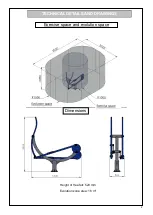

ELLIPTICAL TRAINER

PRODUCT REF

:

S80102

UNIT

ASSEMBLY TIME

The assembly time for this elliptical trainer is estimated at 30 minutes with 2 people (without concreting).

MAINTENANCE

The equipement has to be regularly maintained by the owner. If one of the modules has to be repaired,

users should not be able to access to it until the repair is done. To ensure good use, routine visual ins-

pections are required, paying special attention to the following points: The cleanliness, ground clearance,

surface condition, visible foundations, sharp edges , missing parts, excessive wear of moving parts and

the structural integrity. Moreover, a more thourough functional check should be carried out every two

months on the following points:

- Check that all the screws are correctly tightened

- Remove all the non expected elements (ex: stickers, clothes, ropes,…)

- Fix paint defects if the module has been damaged, using the adapted paint, specified by the manufactu-

rer.

- Replace all damaged or missing parts with a spare part recommended by the manufacturer.

- Check that all the instruction labels stuck on the modules are in condition and are readable. Replace

them if necessary.

- Check the stability of the modules. If one of them is sligthly unfixed from the foundation,

- Check that all the anchors are secure in the ground.

- Clean all dirty parts with soapy water.

Every year, it is recommended to check carefully the ground fixation. In order to do this, remove the dirt

covering the attachment plate, and inspect cautiously the wear of the fixations and of the concrete. Re-

place them if necessary. Check that the screws are firmly tightened.

Note : If the screws untighten too easily, do not hesitate to use Loctite !

WARRANTY

One full year parts and labor guarantee. Every claim regarding condition of the delivered equipment has to

be done within the legal period of the reception of the material. The warranty will not apply to:

- all degradation during the transport.

- all degradation due to use differing from which was intended.

- all degradation due to poor maintenance.

- any defect claimed after the end of the legal period.

- any damaged due to a faulty installation and assembly of the module