Chapter 13 - Tips and tricks for cable testing

48

PROFIBUS Tester BC-700-PB - User Manual

13.2

List of fault indications and remedial measures

The classifying text messages in the graphical user interface of PROFIBUS Tester 5

which describe the cabling errors are kept concisely. The table below lists possible

cabling error messages and provides a detailed description of the discovered fault

indications. The column on the right contains "remedial measures" and further starting

points in order to correctly interpret and to repair the indicated fault.

The PROFIBUS Tester 5 uses amongst other methods impulse reflectometry for

assessing the cabling and classifying and locating errors on the cable. Multiple cable

errors, which exist simultaneously on the cable may result in an imprecise cable test

result. Please bear in mind, the more the corrective repair of the cable is proceeding, the

more precise the cable test results in the corresponding PROFIBUS cable segment will

be.

Electromagnetic interferences may influence PROFIBUS cable testing in a negative

manner because cable conductors may act like an antenna. Please bear this in mind

during cable testing and take care of proper functional earthing of your plant respectively.

Existing high frequency noise voltage may negatively influence the PROFIBUS Tester 5 if

operated by means of the external power supply. We recommend operating on the

PROFIBUS-Tester 5 by means of the built-in battery under the above mentioned prevailing

conditions.

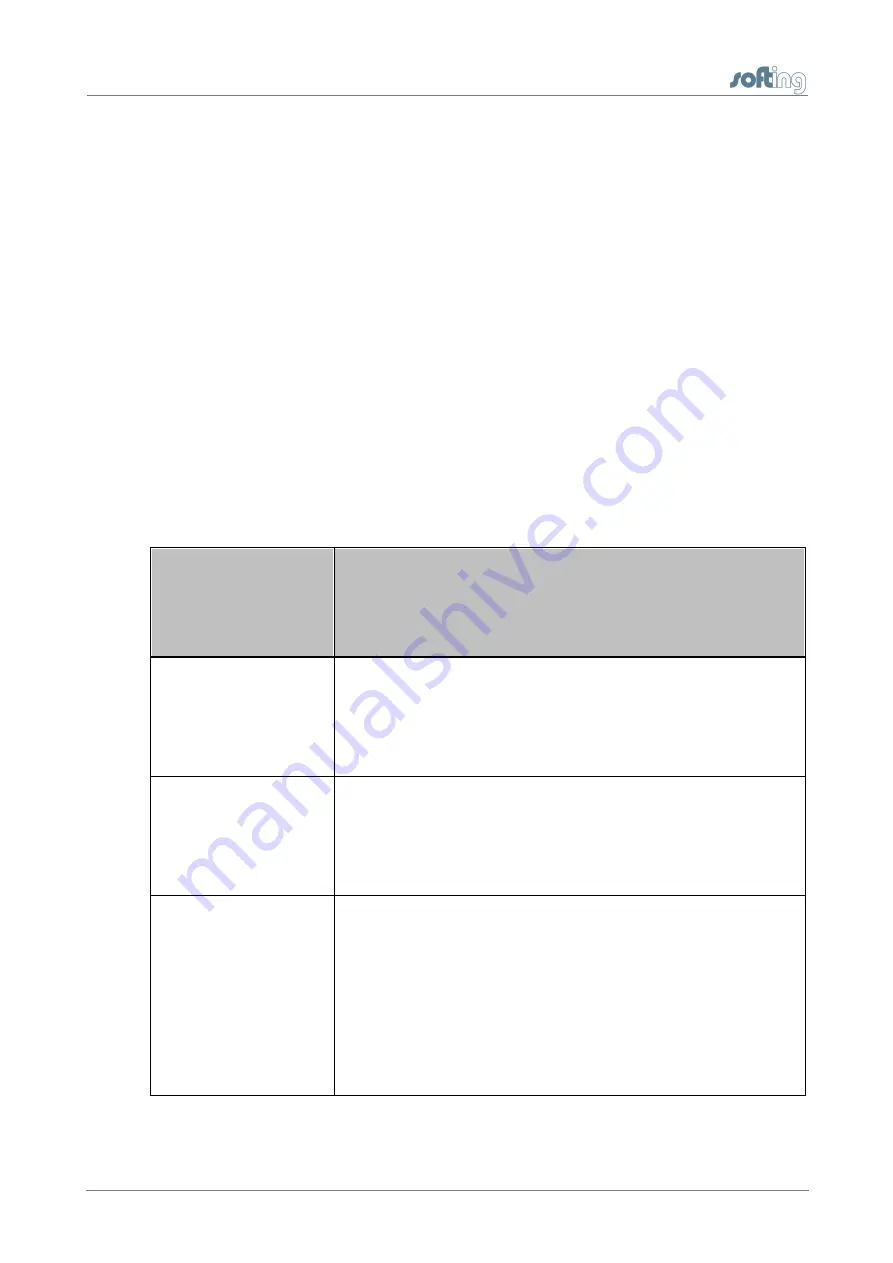

Cable testing error

message from

graphical user

interface of

PROFIBUS-Tester 5

Remedial measures - starting points for correctly

interpreting and repairing the indicated fault

Break on line A

The green signal line of the PROFIBUS-cable is broken. Please

search for damage on the cable in the vicinity of the indicated

error location. Possibly the error could come from a fatigue

breakage or a faultily assembled PROFIBUS-connector. The

green signal line typically is connected to Pin 8 of the

PROFIBUS Sub-D type connector.

Break on line B

The red signal line of the PROFIBUS-cable is broken. Please

search for damage on the cable in the vicinity of the indicated

error location. Possibly the error could come from a fatigue

breakage or a faultily assembled PROFIBUS-connector. The

red signal line typically is connected to Pin 3 of the PROFIBUS

Sub-D type connector.

Break on shield

The shielding conductor is broken in the tested cable segment.

Alternatively electromagnetic shielding is not applied for in a

continuous manner. Please search for damage on the cable in

the vicinity of the indicated error location. Possibly the error

could come from a fatigue breakage or a faultily assembled

PROFIBUS-connector.

In rare cases electromagnetic shielding may be disrupted

intentionally in order to avoid electromagnetic interferences.

Please check this issue with the planning personnel of the

PROFIBUS-facility.