[16]

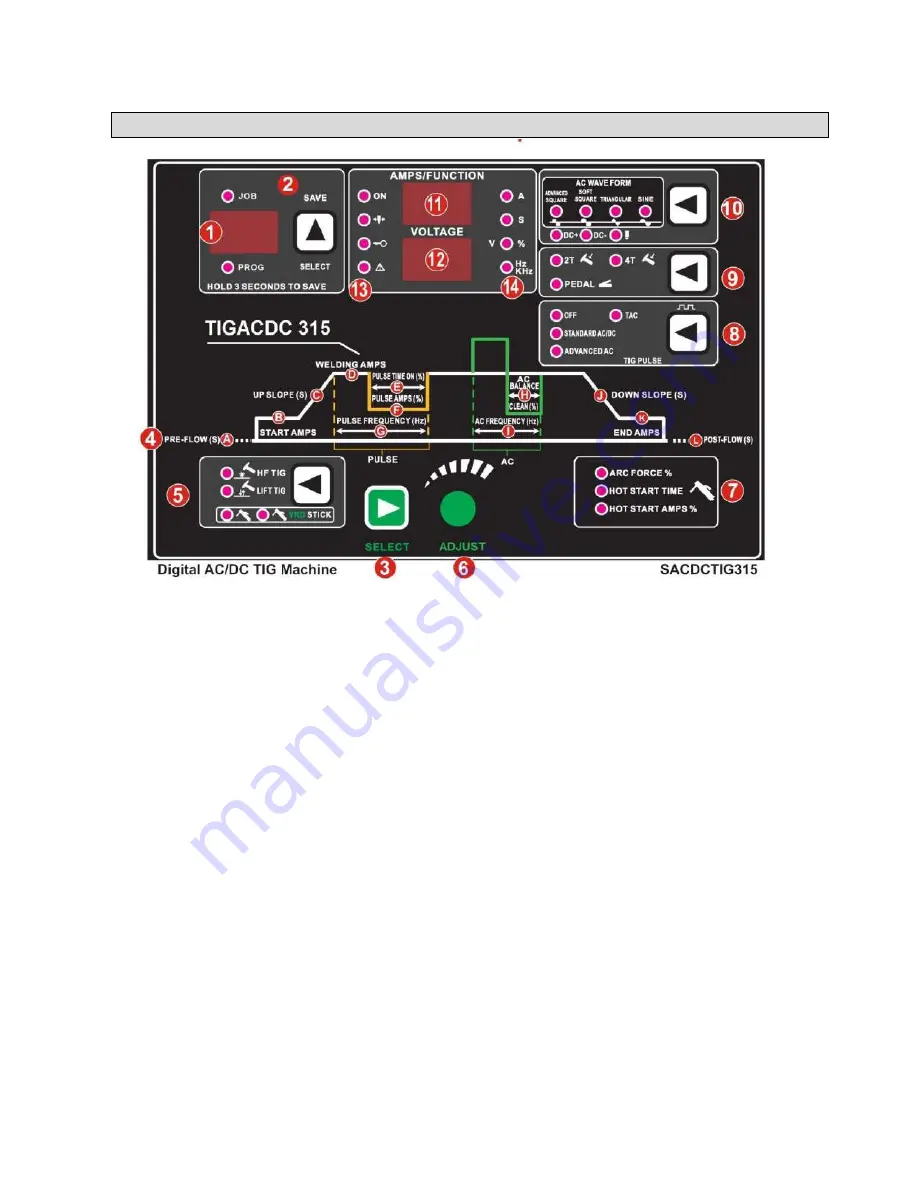

1. Memory store function :

There are memory store programs to enable you to select required parameters for job in hand and then

store to select channel. Press memory button until required program you wish to store is showing in

LED Then enter parameters as required, now press and hold save button for 3 seconds and release,

the green save LED will now light for about 2 seconds and then go out. The parameters have now

been stored. The red select LED will then come back on, if you make any more adjustments these will

not be save until you save again

2. Save button:

to save the parameters on control panel

3. Select :

Parameter selector Button :

Press this button to scroll from left (A) to right (L) to select the

machine parameters an adjust the value of the same within 2 seconds or you have to repeat the

procedure again as LED will move to its initial (D) position.

4. Parameter Sequence : From A to L as explained below :

A. Pre-flow gas :

Adjustable from 0 - 25 seconds, this enables the backed up gas pressure to be

released from torch before actual arc is started. Common settings for most application is about .3 to.5

seconds - If welding stainless steel etc sometimes a longer pre-flow is required.

6.

WELDING PARAMETER SELECTION AND SETTING [ FRONT PANEL]

Summary of Contents for SI-TIG-300

Page 31: ... 28 9 TIG WELDING TORCH DETAILS ...

Page 32: ... 29 ...

Page 33: ... 30 10 ARGON FLOWMETER REGULATOR DETAILS ...

Page 34: ... 31 ...