29

11. CHECKS AND ADJUSTMENTS

A DT is a precision instrument that requires fine adjustments. It must be inspected

and adjusted before use so that it always performs accurate measurements.

• Always perform checking and adjustment in the proper sequence beginning

from "11.1 Plate Level" to "11.4 Optical Plummet".

• In addition, the instrument should be inspected with special care after it has

been stored a long time, transported, or when it may have been damaged by a

strong shock.

• Make sure the instrument is securely set up and stable before performing

checks and adjustments.

The bubble tube is made of glass, so it is sensitive to temperature changes or to

shock. Check and adjust it as outlined below.

X

PROCEDURE Checking and adjusting

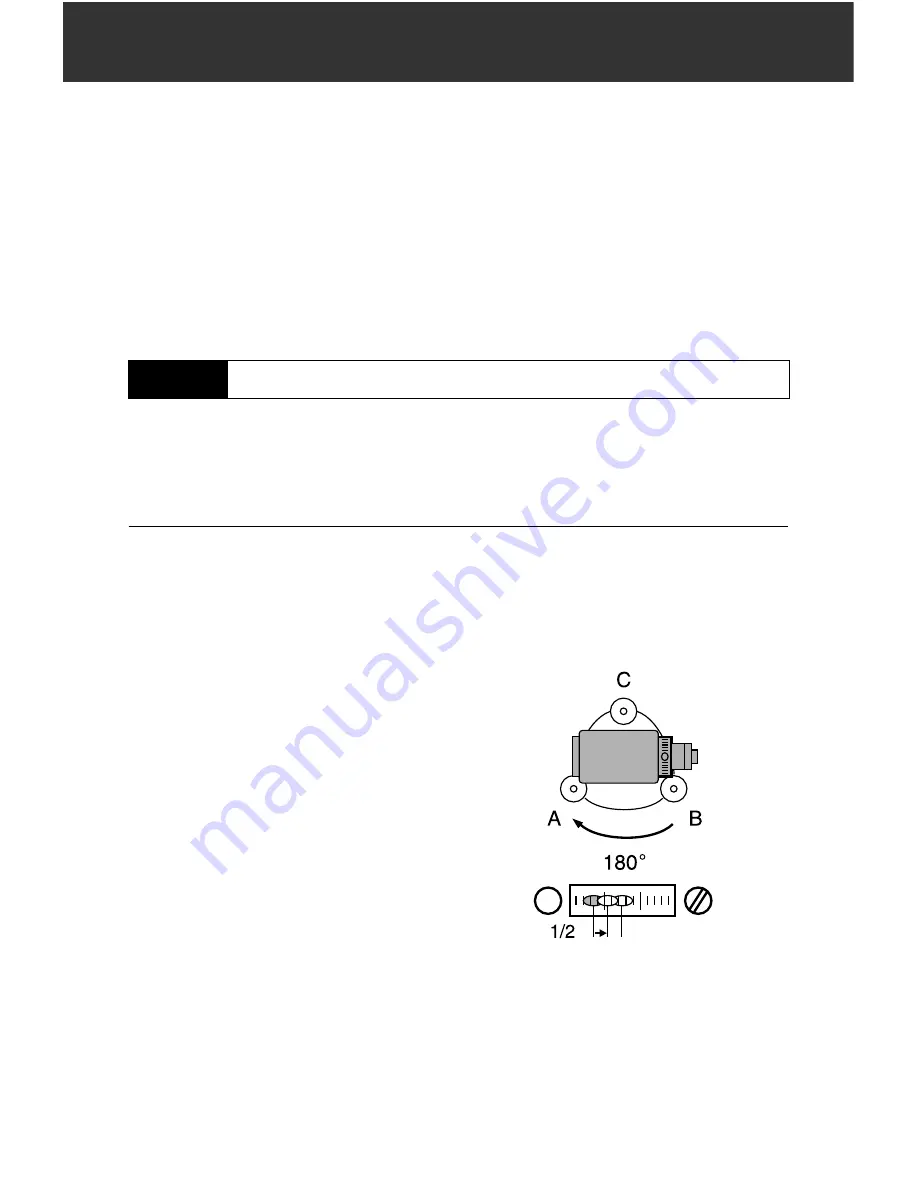

1. Level the instrument and check the

position of the bubble in the plate

level.

C

"5.2 Leveling", steps 3 to 5.

2. Turn the upper part through 180

°

and

check the bubble position.

If the bubble is still centered, no

adjustment is necessary.

If the bubble is off-center, adjust as

follows.

3. Correct half of the bubble

displacement using leveling foot screw

C.

11.1

Plate Level