Series 200 Power Conditioners

Instruction Manual

2.3

SELECTION OF INPUT CIRCUIT BREAKERS

As with all transformer based equipment, ferroresonant transformers are characterised by an

inrush current when switched on. For this reason it is recommended that delayed-trip type

circuit breakers are used when switching power conditioner circuits. In Australia the Heinemann

CF1 and CF3 (for 1 and 3 phase circuits respectively) breakers are appropriate. These are

hydraulic/magnetic type breakers with variable sensitivity. A “Curve 1” type circuit breaker will

provide the correct protection characteristics whilst delaying the trip function during the

transformer in-rush. Select the breaker appropriate to the next current rating above the nominal

rating of the power conditioner.

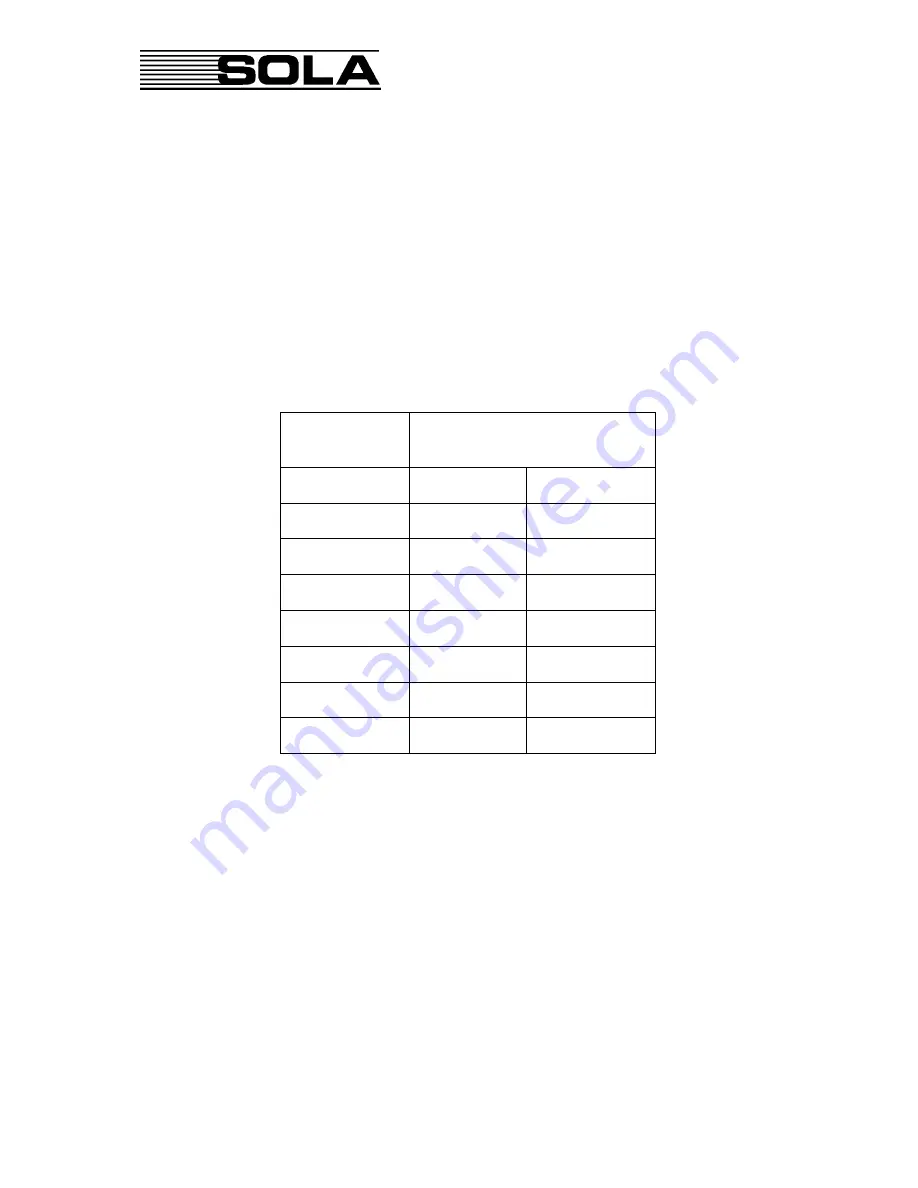

Table 2 is a guide for cabling between the circuit breaker and power conditioner. The installer

must satisfy himself that the cable size is correct for the installation.

Cross

Sectional Area

Current Rating

(sq. mm.)

3 Phase

1 Phase

4

25

25

6

32

32

10

40

50

16

50

63

25

80

80

35

92

105

50

110

125

70

140

155

Table 2. Cable Selection Guide

2.4

POWER UP

When the installation has been approved by the local power authority, the power conditioner

may be energised with load equipment switches in the OFF position. A few seconds after

energisation, load equipment may be switched on. Whilst no special commissioning procedure

is required, the following may prove useful for future reference:

Using a good quality (preferably True-RMS) voltmeter and current tongs, measure and record

all input and output voltages and currents. Also record details of load equipment and running

time of the power conditioner from cold. Output voltage will be 1 or 2% higher than normal until

the unit has operated for 2 hours or more. Check output voltage against nameplate and

performance data - Section 3.1. If output voltage is incorrect, call Invensys Service on 1300 303

059

- 7 -