19

ADJUSTMENTS

THE AIM OF MICRODOSING IS TO BETTER DIS-

TRIBUTE BOTH FINE AND REGULAR SEEDS IN

SMALL NUMBERS.

THE CORRECT VALUE TO USE F-MICRODOSING

MODE FOR FINE SEEDS CAN BE FOUND IN THE

DOSING TABLES (SEE SECTION 10- DOSAGE TA-

BLES).

CHECK THE CONDITION OF THE CLEANING

BRUSH BEFORE STARTING TO SOW FINE SEEDS.

WHEN MICRODOSING FINE SEEDS, DO NOT EX-

CEED NUMBER 25 IN ADJUSTING SCALE (1, FIG.

41)

OPEN THE SEED INLET TO THE METERING UNIT

(FIG. 44).

Fig. 44

A

6.3.1 REGULAR SEEDS (position N)

To adjust the sowing to

REGULAR SEEDS

, proceed as fo-

llowing:

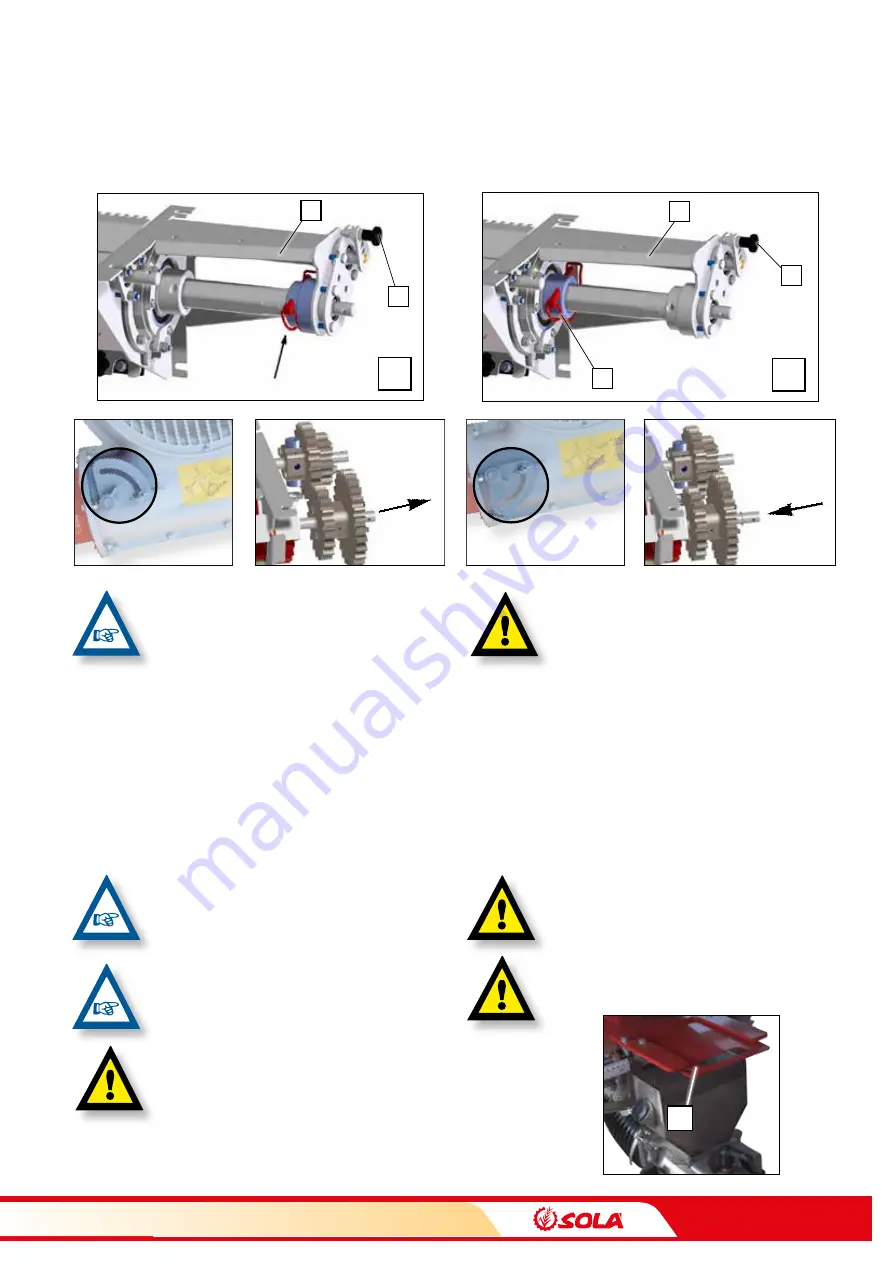

Fig. 40

1

4

Fig. 38

N

Fig. 39

N

F

THE LOCKING RING MUST BE IN NORMAL POSI-

TION (IN RED, FIG. 38).

1-

Slightly pull and turn the spindle (4, Fig. 38) to adjust the

dosing.

2-

Set the pinion gears in

position N

(Fig. 40).

3-

Set the fan adjusting switch to

position N

(Fig. 39).

6.3.2 FINE SEEDS (position F)

To adjust the sowing to

FINE SEEDS

, proceed as following:

Fig. 43

1

3

4

Fig. 41

F

Fig. 42

N

F

IN ORDER TO BE ABLE TO CHANGE THE PO-

SITION OF THE LOCKING RING TO MICRODO-

SING, IT IS ESSENTIAL THAT THE SPINDLE (4) OF

THE METERING UNIT CAN TURN FREELY AND

THE HOPPER IS EMPTY.

1-

Place the locking ring in

position F

(3, Fig. 41).

2-

Turn the spindle (4, Fig. 41) to adjust the dosing.

3-

Set the fan adjusting switch to

position F

(Fig. 42).

4-

Fit the pinion gears as shown in the picture (Fig. 43).

5-

Set the electronical controller to MICRO mode (see sec-

tion 8. ELECTRONICAL CONTROLLER).

Summary of Contents for 600/43

Page 40: ......

Page 41: ...41 NOTES 12 NOTES DATE NOTES ...

Page 42: ...42 NOTES DATE NOTES ...

Page 43: ......

Page 44: ...WWW INTEGRUM ES ...