Professional, Vision

11

1408TU0710

J

Note:

Pay attention to the maximum load-bearing

capacity of the modules, with consideration of

wind and snow load zones, the terrain category

and the height of the building.

J

Installation data:

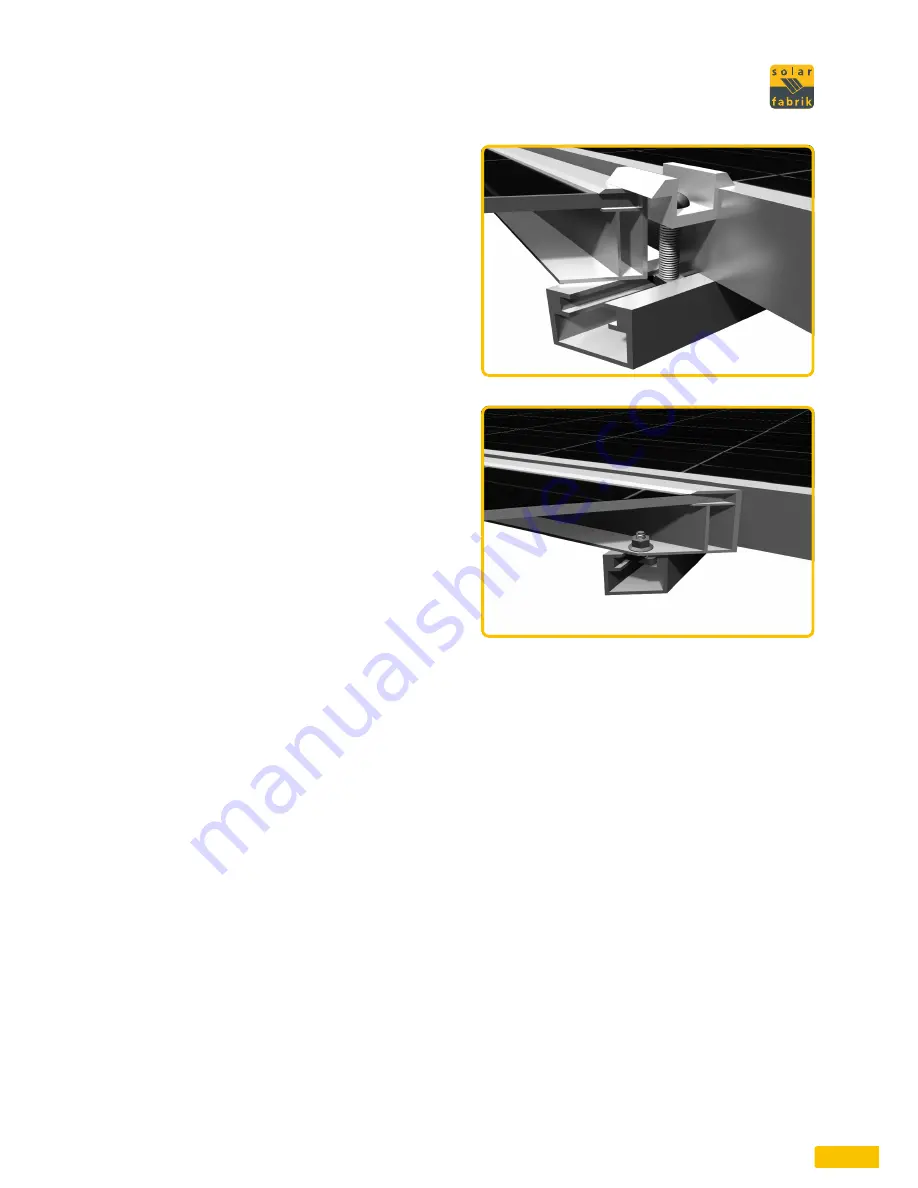

There are several methods to connect the modules

to substructure: by clamping the modules from

the front (example A) or by bolting the modules

from the back (example B) using the provided

attachment holes.

Use a torque wrench for installation. The required

tightening torque for the above samples is

14.8 lb ft (20 Nm). Use M6 bolts made of V2A.

Only use the provided holes for installation.

If any further holes are drilled, the warranty

will no longer apply. For laminates, use the

explicit installation instructions contained in the

installation manual of the selected mounting

system. Always use appropriate corrosion-proof

fixing materials for installation.

Example A: Clamping wing

Example B: Direct bolting