SAB12-0669_02_Installation and Maintenance Manual SFxxx-S

10

7. Electrical Installation

7.1 Electrical Wiring Safety Precautions

The sum of Voc of modules in series must not exceed the maximum system voltage of the module under any

condition. Reverse current applied to the modules must not exceed 7 A.

Do not touch or handle the PV module, terminal box or the end of output cables with bare hands.

Do not carry out installation when PV modules, installation tools or installation area are exposed to water.

Ensure that the connection parts between SF PV modules and power receiving devices are isolated and waterproof.

Using SF PV modules with insufficient isolation and waterproofing could result in an electric shock, an electric leak or

an accident.

Keep the junction box and the module connector away from any liquids until connectors are mated. Failure to do this

may cause faulty wiring.

Components interconnecting the modules must be compatible with the connectors, and must provide proper system

operation and fault protection.

Inverters must meet the technical requirements of SF modules.

Do not connect the PV modules directly to loads such as motors. Variation in output power may damage the motor.

Observe and understand the safety instructions of batteries. Their misuse can result in serious bodily injury due to

high electrical current.

Cables should be adequately protected from damage by wildlife.

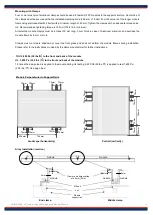

7.2 Grounding

Grounding Cautions

Be aware of the necessary grounding requirements prior to installation. Your local authorities can help you further.

Install arrestors, surge absorbers or any other appropriate lightning protection tools as needed.

Module frames, mountings, connection boxes and metal conduits should be connected to an earth ground for lightning

protection, in accordance with local, regional and national standards and regulations.

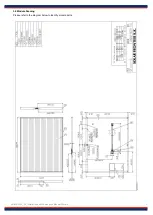

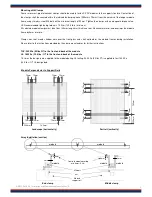

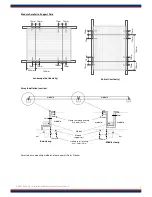

Grounding holes

( 4

mm) on the aluminum frame of the SF PV modules are provided to accommodate grounding.

Use a grounding wire made of copper, not smaller than 2 mm sq (14 AWG). Temperature rating of the conductors

must be between - 40

°

C to 85

°

C. Ensure that the crimping terminal is tightly tied to the module frame with a rolling

thread screw and a lock washer to ensure electrical contact.

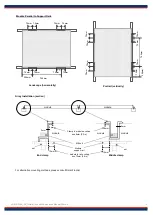

Grounding devices such as module clamps with an integrated grounding pin, serrated washers, grounding clips or

lugs, designed for bonding photovoltaic modules to the mounting structures may also be used for grounding as

described in National Electrical Code Section 250. These grounding devices shall be made in conformance with the

grounding device manufacturer instructions. Consult with the grounding device manufacturer to identify the

appropriate grounding and bonding device for your mounting structure or design.

For alternative grounding methods, please consult Solar Frontier.

UL: The module with exposed conductive parts is considered to be in compliance with UL1703 only when it is electrically

grounded in accordance with the instructions presented below and the requirements of the National Electrical Code.

Summary of Contents for SF135-S

Page 10: ...6 9...

Page 11: ......

Page 14: ...8 9 B B BB 1 BB BB BB ABBB B CCC 1...

Page 18: ......

Page 49: ...SAB12 0669_02_Installation and Maintenance Manual SFxxx S 13...