|

27

October 2019

24VDC Power Hub 2500 Operator Manual

Heat and Derating

The function and efficiency of all electronic equipment is related to and dependent upon the

temperature at which it is operating. All equipment performs optimally within a narrow temperature

range and less so as the temperature exceeds the upper end of that range. PV panel output drops

off significantly in high heat as well. The Power Hub generates heat as a by-product of processing

incoming PV power. Under normal circumstances, the amount of heat generated in this way will not

exceed the rated temperature for the Power Hub to function at its rated capacity.

Causes of Overheating

The two (2) most common reasons for the Power Hub to overheat are high ambient temperature

and solar loading (heat accumulation due to the sun shining directly the Power Hub). These two

factors work together to elevate the internal operating temperature to the point where the solar

chargers may automatically derate or even temporarily suspend output to prevent damage to

their internal electronics. The solar chargers are rated to provide full power up to 104 ºF (40 ºC).

Performance of the Power Hub will decline (charging current reduced) as the temperature increases

or is sustained above this value.

Note:

The charging current reported by the Power Hub battery monitor will also approach zero

(0) A as the batteries approach a fully-charged state.

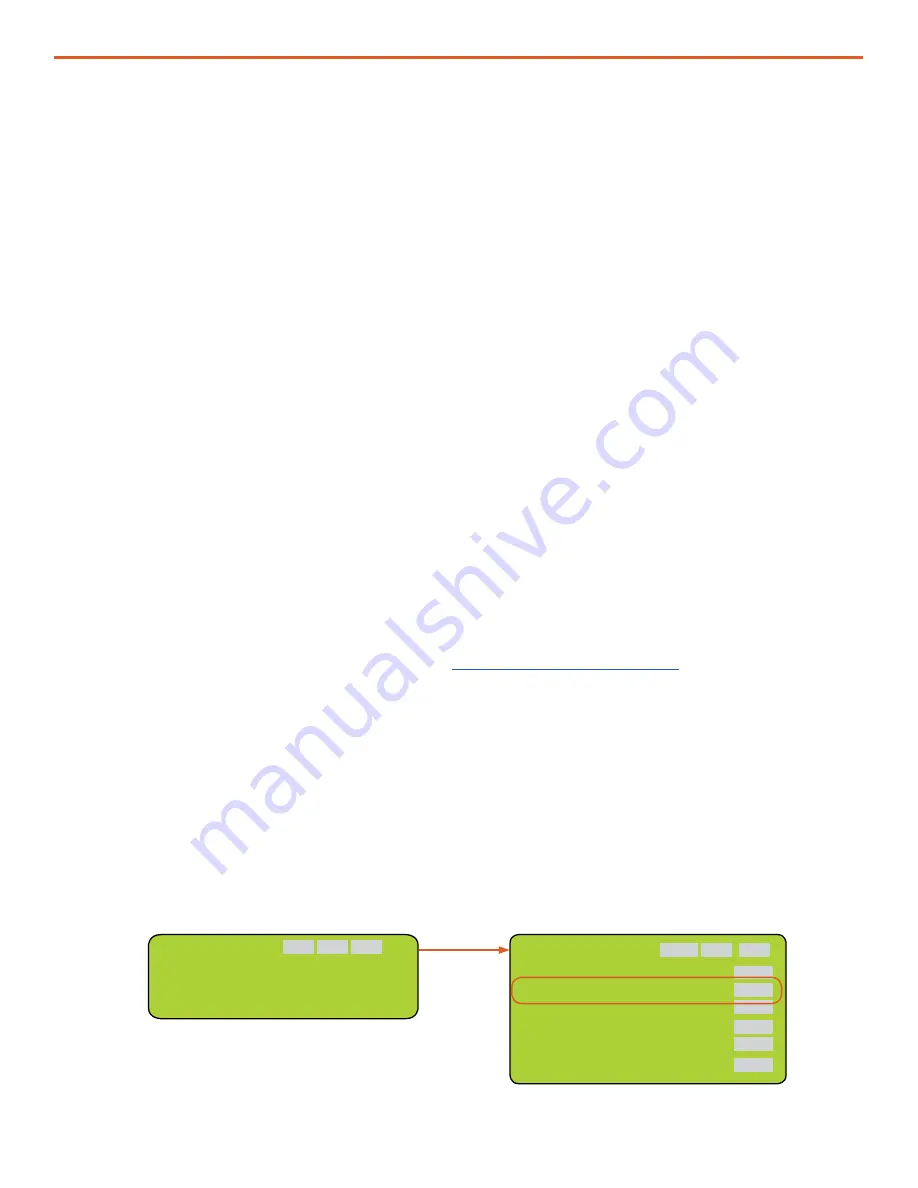

DEVICE LIST

Battery Monitor

Time

100% 0.0A

0.0W

Solar Charger #1

Solar Charger #2

Solar Charger #3

>

>

>

>

Battery Monitor

Battery

Time

26.33 V 0.0A

0.0W

State of charge

Temperature

Starter voltage

Consumed AmpHours

Time-to-go

Relay state

100%

0.01V

0.0Ah

--

Off

75 ºF

Figure 22. Power Hub internal temperature report on user interface

Power Hub Internal Cooling

Thermostat-controlled, internal cooling fans turn on at ~104 ºF (40 ºC) to maintain the internal

temperature within the optimal operating range. The fans are audible when operating. Clogged

air intake filters can significantly exacerbate heat-related problems, so they should be cleaned as

often as necessary to maintain maximum airflow.

Clean or replace the air filter

monthly, or more

frequently if operating in very dusty environments. Do not operate the Power Hub in direct sunlight

or directly on the ground. It should be placed in a shaded, well-ventilated location. Proper air filter

maintenance and shading the Power Hub will help to ensure that the internal temperature does not

reach critical levels.

Power Hub Internal Temperature Report

The Power Hub has a sensor that measures and reports the internal temperature. The internal

temperature of the Power Hub (NOT the batteries) is reported in the Battery Monitor menu page. To

access this and other battery-related data, press the Menu button to show the device list. Select/

highlight “Battery Monitor” and either right-click or press the Select button to display.