3906

1381

+

-

Construction - Motor Mount Support & Drive Wheel

7

+

-

11

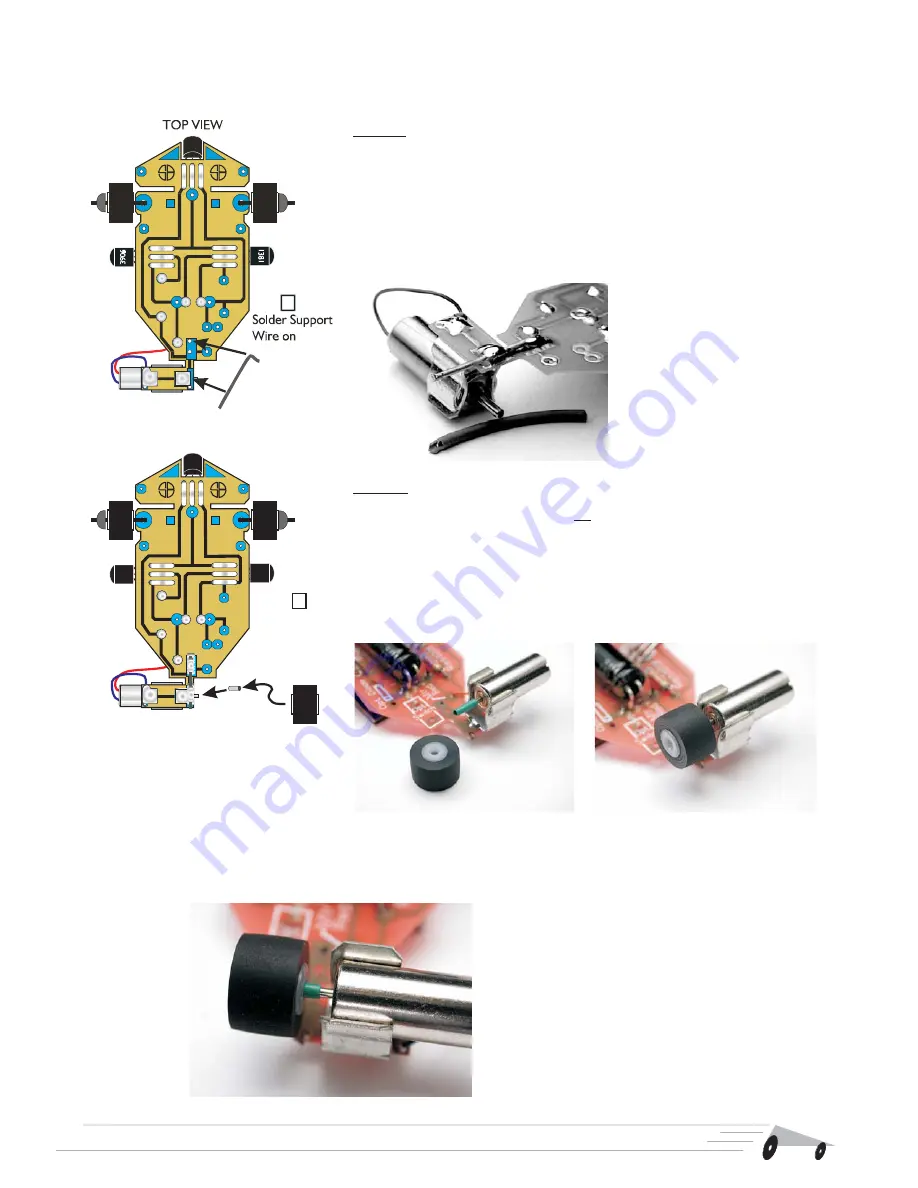

Step 11: Find your small thick piece of wire, and pull the insulation off

so you are left with a small piece of solid

copper wire.

Bend one end 90 degrees down, and

shown

on the illustration. This gives your motor mount more strength, and allows

you the option of aligning the motor so you can adjust where your

SolarSpeeder goes.

(SAVE

the insulation - you’ll need it!)

solder the wire onto the pads

Mount wire

insulation on

motor shaft,

then wheel

12

Step 12: Time to mount the wheel; Let’s start by taking that insulation you

saved from the last step, and cutting it down to a short length about 5/32 long

(here-make it as long as this line:

). Slide it onto the motor shaft, making

sure you

shove it all the way to the side of the motor (it rubs, and slows

it down).

Slide the wheel on top of the sleeve, and glue the sleeve, wheel, and motor

shaft together with the

amount of glue. You don’t need much, and you

don’t want to accidently glom up the motor with too much glue!

don’t

tiniest

Close-up of stripped copper wire

soldered onto motor mount support

pads

Slide the sleeve onto the motor

shaft...

...then add the wheel. A drop of glue

in the wheel hole to secure the

works, and you’re done!

This is how it looks finished... almost.

We’ve pulled the sleeve and motor apart a

bit so you can see how they go together.

When finished, the wheel sits right on top

of the sleeve.

Note that there’s a space between the

sleeve and motor body, so there’s no

chance of rubbing!